PRODUCT

Contact withus for any advice

Need help? Talk to an expert

+86 19068026712

Cleaningsonic S-Series Benchtop Ultrasonic Cleaner | Normal Wave+Heating+Timer

Cleaningsonic offers full series benchtop ultrasonic cleaners from 1.3L to 30L capacity, 40KHz industrial transducers, digital temp/time control, 60W-900W power. Suitable for lab, electronics, hardware, medical industries. OEM supported, global power adapters.

S-Series Benchtop Ultrasonic Cleaner

- Function: normal wave+Heating+Timer

- Capacity: 1.3L-30L

- Sonice Power: 60W-900W

- Frequency: 40KHz

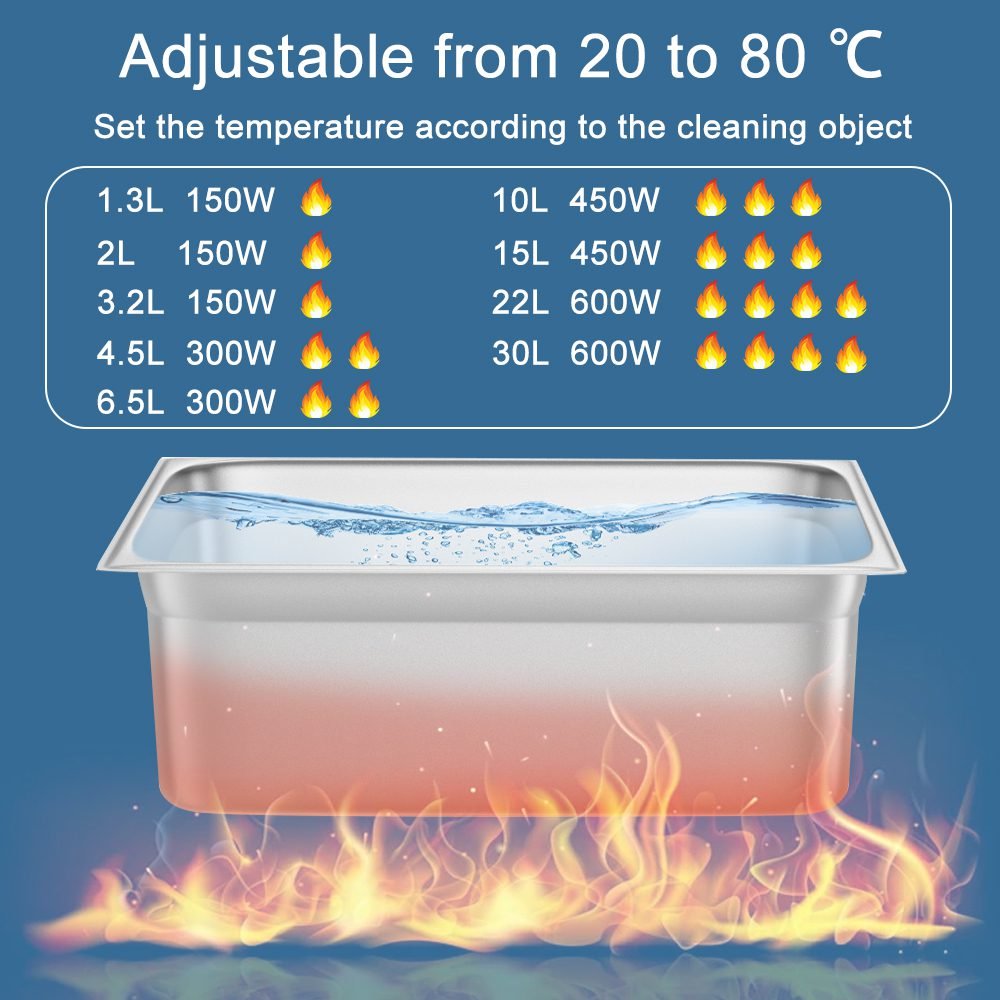

- Temp Range:0-80°C

- Timer Range: 0-99 min

Benchtop Ultrasonic Cleaner - 1.3L to 30L Capacity | 40KHz | Smart Digital Control

Product Overview of Ultrasonic Cleaning for Engine Components

Benchtop Ultrasonic Cleaner Full Series – Comprehensive Cleaning Solutions from Lab to Workshop

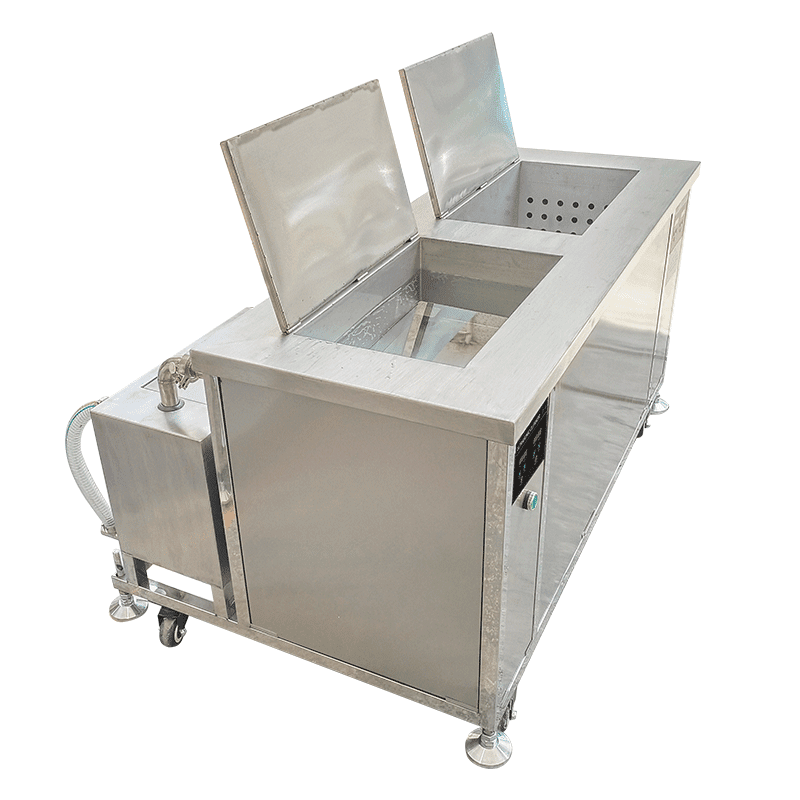

The Cleaningsonic benchtop ultrasonic cleaner series covers 12 capacity specifications from 1.3L to 30L, providing complete solutions from micro laboratory cleaning to medium industrial cleaning. This product series adopts unified 40KHz industrial sandwich piezoelectric transducer technology, combined with intelligent digital control systems and adjustable heating functions, ensuring excellent cleaning performance in various application scenarios.

As a professional industrial ultrasonic equipment manufacturer, we provide global customers with standardized, modular, and customizable cleaning equipment solutions. From small electronics repair shops to large manufacturing enterprises, from scientific research laboratories to medical service institutions, our benchtop cleaner series can find suitable models for all.

Series Overview of Ultrasonic Cleaning for Electric Vehicle (EV) Parts

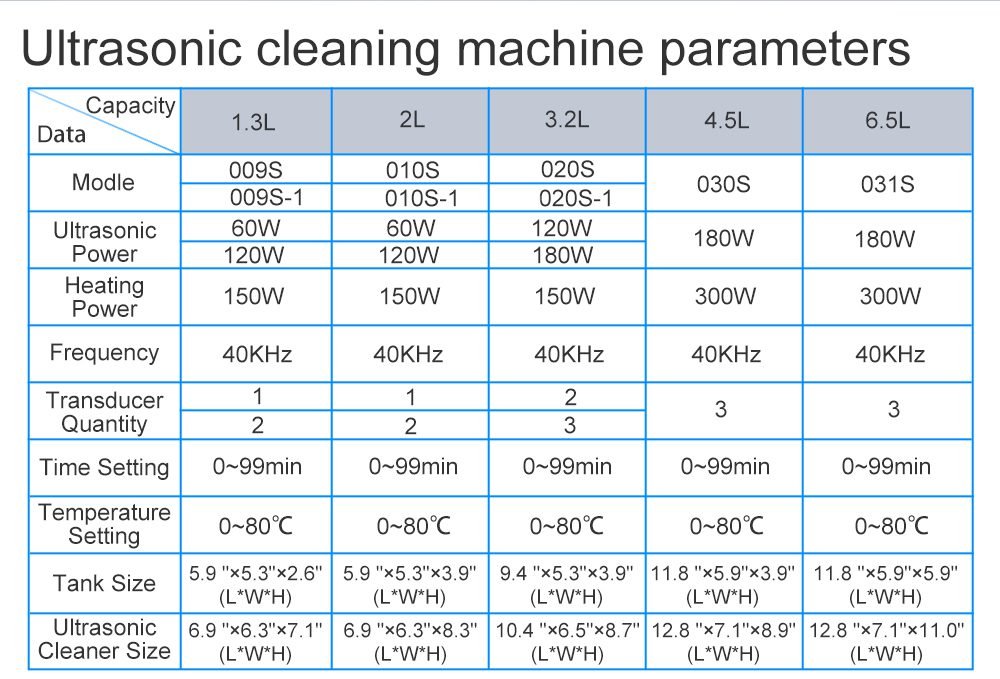

Small Series (1.3L-6.5L) - Precision Cleaning Experts

Capacity

Model Series

Ultrasonic Power

Heating Power

Transducers

Applications

1.3L

009S/009S-1

60W/120W

150W

1/2 units

Jewelry, glasses, watches

2L

010S/010S-1

60W/120W

150W

1/2 units

Dental tools, small parts

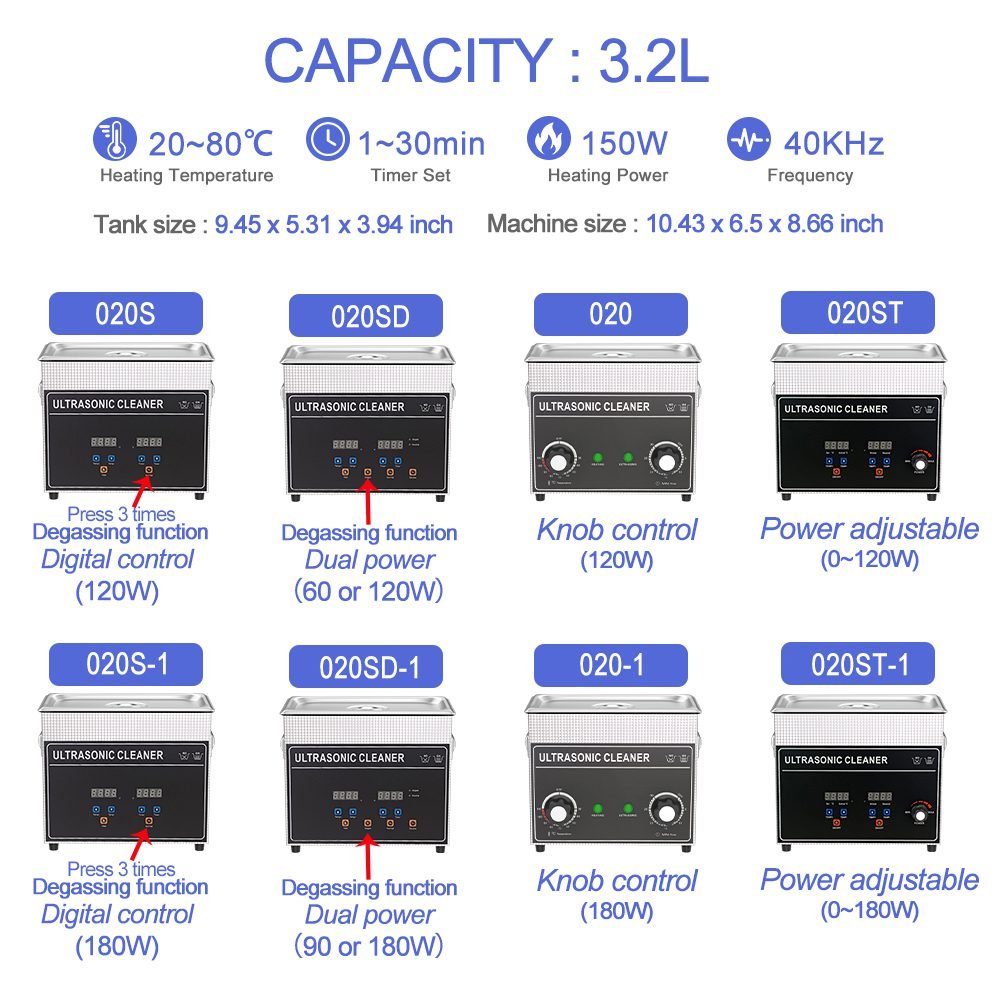

3.2L

020S/020S-1

120W/180W

150W

2/3 units

Labware, electronic components

4.5L

030S

180W

300W

3 units

Small molds, tools

6.5L

031S

180W

300W

3 units

Automotive small parts, repair tools

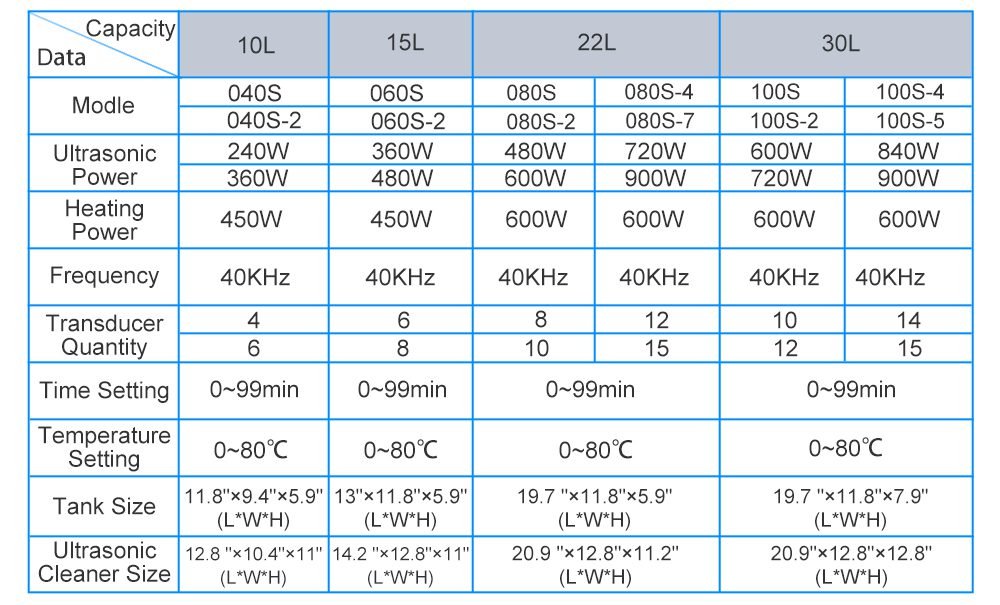

Medium Series (10L-30L) - Industrial Cleaning Main Force

Capacity

Model Series

Ultrasonic Power

Heating Power

Transducers

Applications

10L

040S/040S-2

240W/360W

450W

4/6 units

Laboratory batch cleaning

15L

060S/060S-2

360W/480W

450W

6/8 units

Small-medium workshops

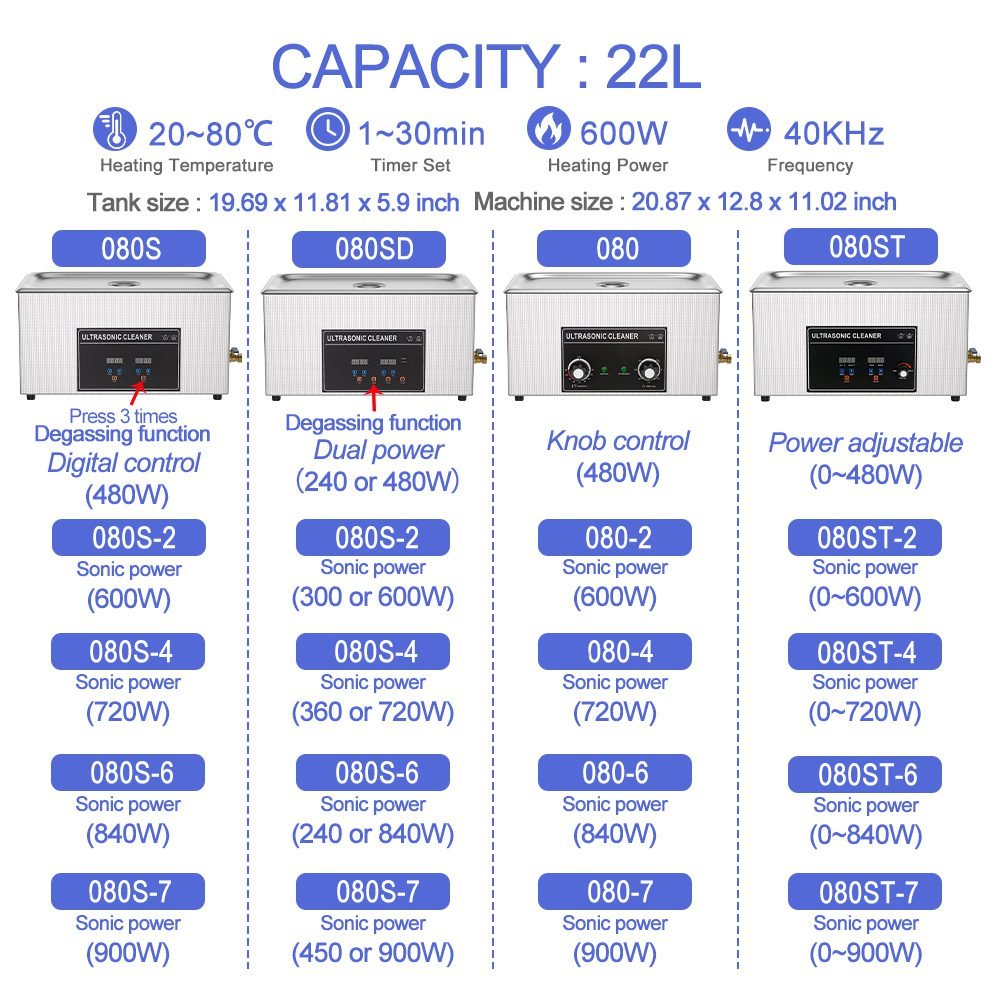

22L

080S series

480W-900W

600W

8-15 units

Auto repair, mold cleaning

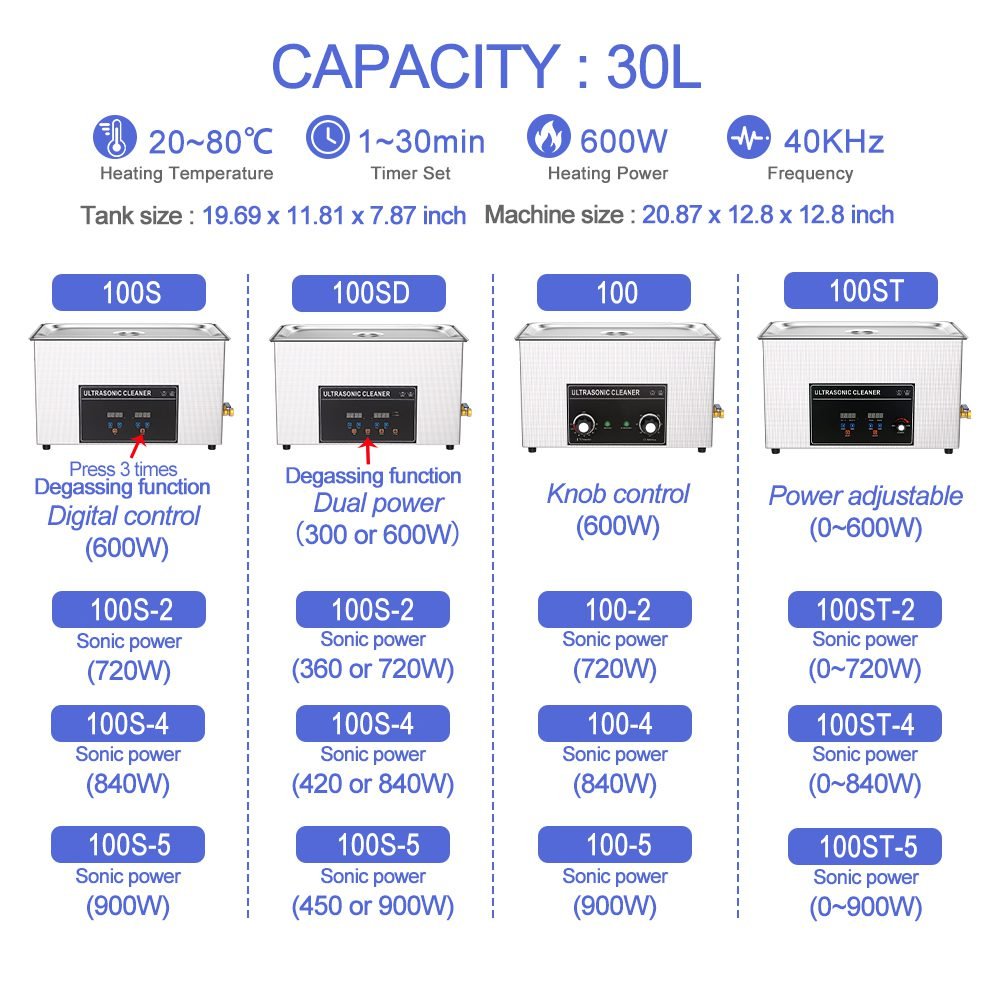

30L

100S series

600W-900W

600W

10-15 units

Industrial batch production

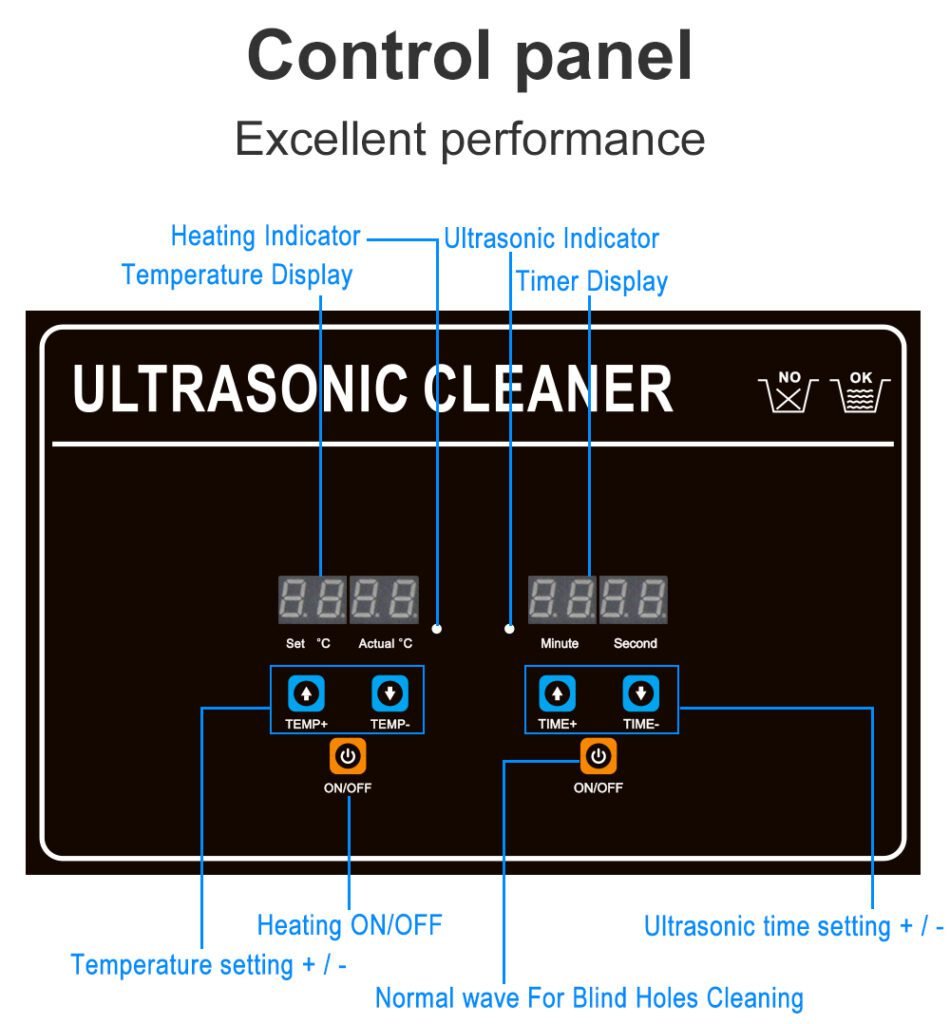

Core Technical Specifications of Ultrasonic Cleaning for Power Tools

Unified Technology Platform

Ultrasonic Frequency: All series 40KHz (±3%)

Control Method: Digital intelligent control (S series)

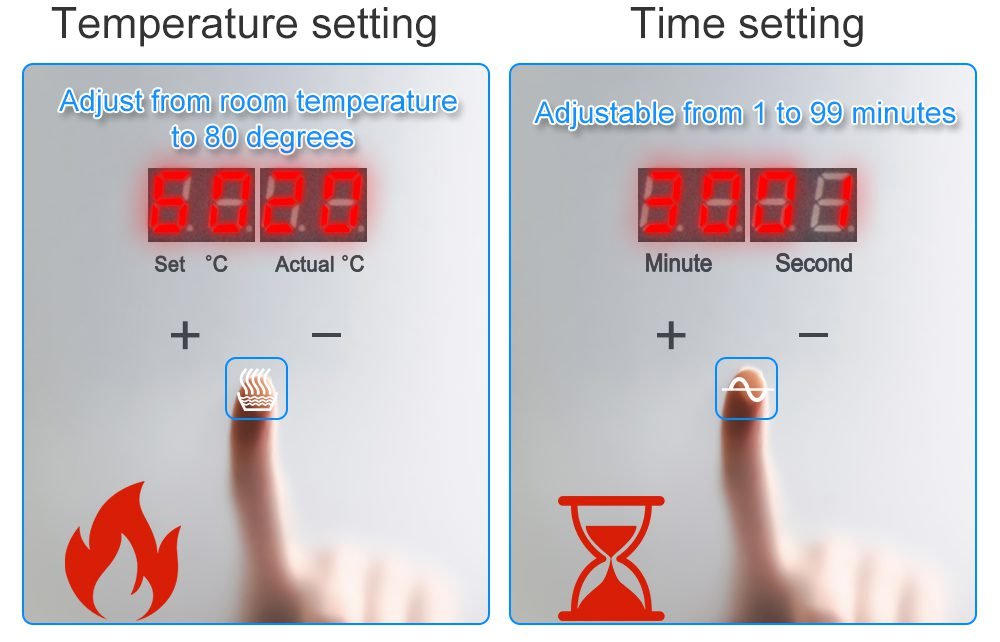

Temperature Control: Room temp-80°C adjustable, ±1°C accuracy

Timer Range: 1-99 minutes adjustable

Heating Function: Standard for all series, 150W-600W power

Display System: Dual digital display (set temp/actual temp, time)

Technical Features

Sandwich Piezoelectric Transducer Structure

High energy conversion efficiency

Long-life design, stable and reliable

40,000Hz high-frequency vibration

Intelligent Digital Control System

Independent heating/ultrasonic switches

Independent temperature/time adjustment

Real-time operation status display

Industrial-grade Structure Design

304 stainless steel cleaning tank

Corrosion-resistant, easy to clean

Compact benchtop design, space-saving

Detailed Specifications Tables of Ultrasonic Cleaning for Injection Molding Tools

Small Series Technical Parameters

Medium Series Technical Parameters

Product Advantages of Ultrasonic Die Cleaner

Advanced Ultrasonic Technology

40KHz High-frequency: Uniform frequency across all series

Sandwich Transducers: Patent structure, >85% efficiency

Uniform Sound Field: Scientifically arranged transducers

Intelligent Control System

Dual Digital Display: Real-time monitoring

Independent Control: Separate heating/ultrasonic switches

Long Timer Range: 1-99 minutes for various needs

Precise Temp Control: ±1°C accuracy

Industrial-grade Quality

304 Stainless Steel Tank: Food-grade material

Corrosion-resistant: Suitable for various chemicals

Compact Design: Space-saving benchtop design

Safety Features: Overheat protection, leakage protection

Global Adaptability

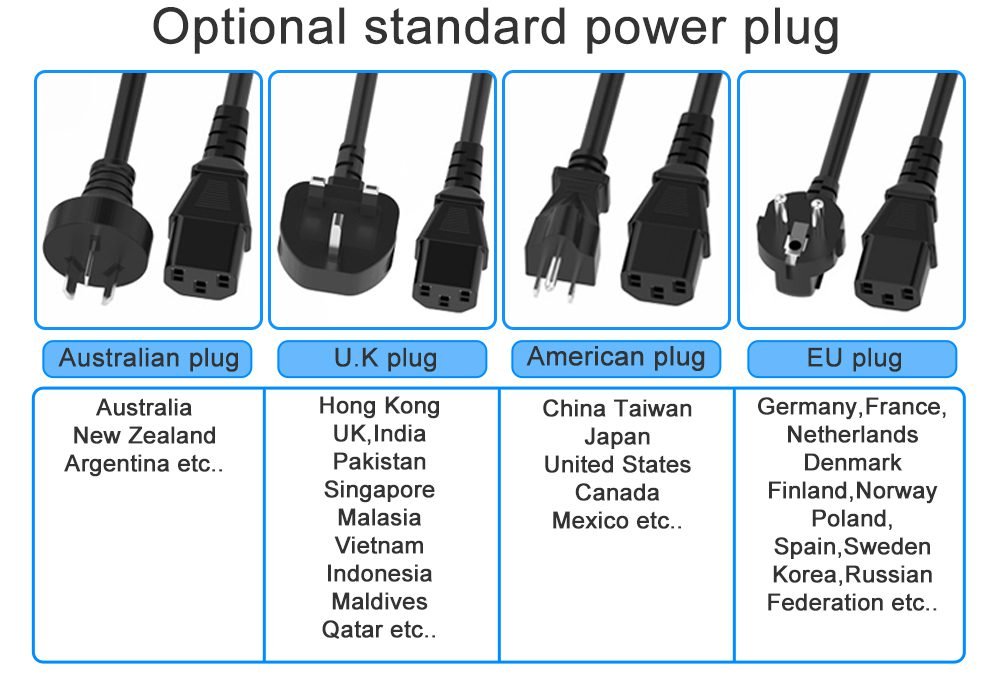

Multi-voltage Options: 110V/220V selectable

Global Plugs: AU, UK, US, EU plugs supported

Multi-language Interface: Customizable operation interface

International Certifications: CE, RoHS compliant

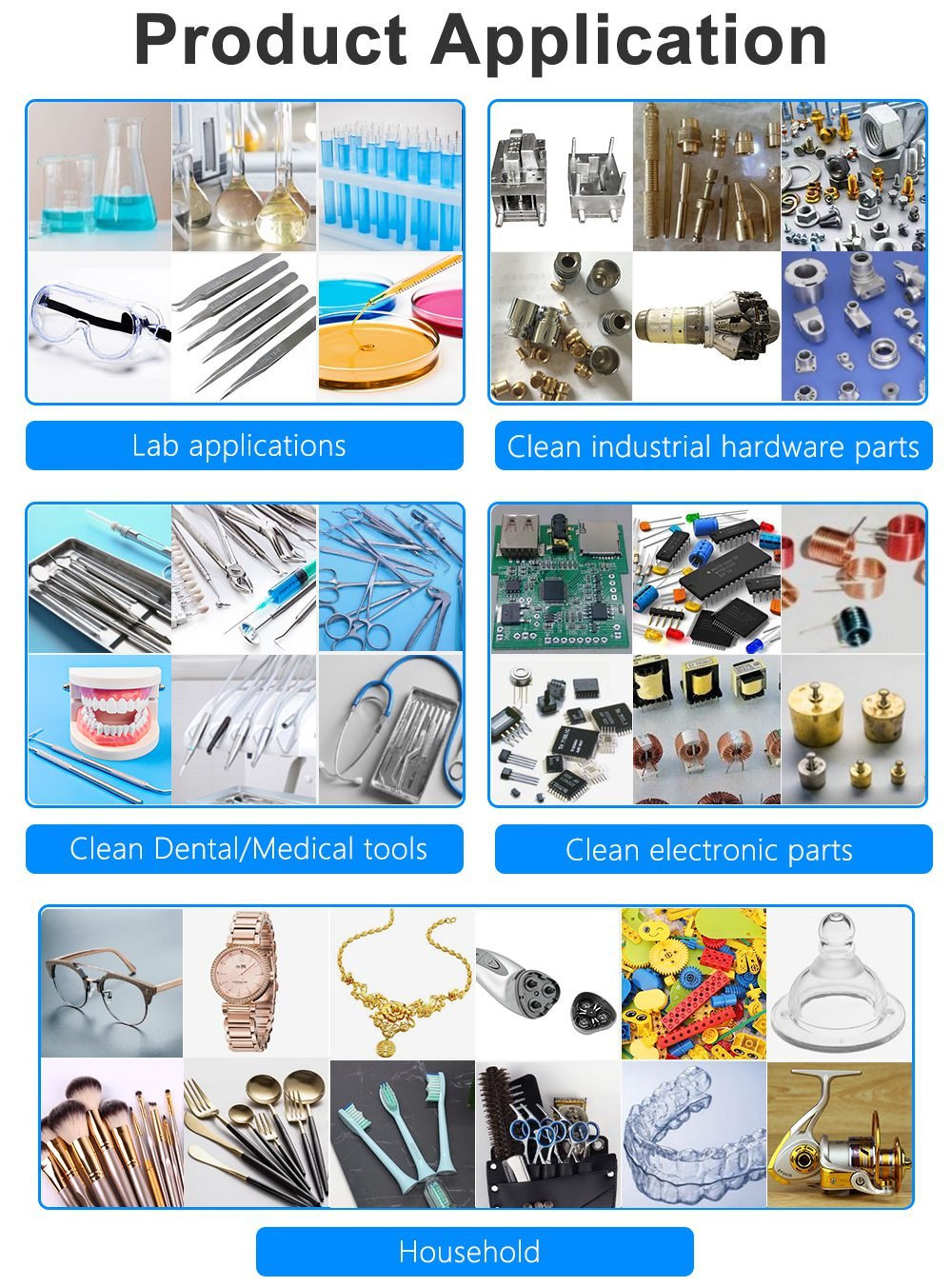

Application Solutions of Ultrasonic Cleaning for Electric Motors

Laboratory & Research

Recommended Models: 1.3L-10L series

Cleaning Objects: Labware, glass instruments, sample containers

Special Requirements: Contamination-free, residue-free

Support Services: Laboratory-specific cleaning solutions

Electronics Manufacturing

Recommended Models: 3.2L-15L series

Cleaning Objects: PCB boards, components, connectors

Technical Advantage: Effective flux removal, no damage

Quality Improvement: Higher yield rates, less rework

Jewelry & Optical

Recommended Models: 1.3L-4.5L series

Cleaning Objects: Jewelry, watch parts, eyeglasses

Cleaning Feature: Gentle yet thorough, no surface damage

Business Value: Enhanced appearance, customer satisfaction

Medical Equipment

Recommended Models: 2L-10L series

Cleaning Objects: Surgical instruments, dental tools

Hygiene Standards: Pre-disinfection cleaning requirements

Safety Assurance: Thorough cleaning, reduced infection risk

Automotive & Mechanical

Recommended Models: 6.5L-30L series

Cleaning Objects: Engine parts, tools, molds

Cleaning Results: Complete removal of grease, carbon, debris

Efficiency Improvement: 5-10 times faster than manual

Mold Manufacturing

Recommended Models: 15L-30L series

Cleaning Objects: Injection molds, die-casting molds

Economic Benefits: Extended mold life, reduced downtime

Technical Support: Mold-specific cleaning solutions

Model Selection Guide of Ultrasonic Cleaning for Machine Parts

Small Applications (Personal/Small Business):

├── Jewelry & Glasses: 1.3L-2L

├── Dental Tools: 2L-3.2L

├── Electronics Repair: 3.2L-4.5L

└── Laboratory Ware: 4.5L-6.5L

Medium Applications (Enterprise/Institution):

├── Lab Batch: 10L-15L

├── Workshop Repair: 15L-22L

├── Small Batch Production: 22L-30L

└── Mold Cleaning: 22L-30L

Operation & Maintenance of Ultrasonic Cleaning for Plastic Molding Tools

Standard Operation Process

Preparation

Select appropriate model and capacity

Prepare cleaning solution and water

Check power compatibility

Equipment Setup

Fill with appropriate cleaning liquid

Set cleaning temperature

Set cleaning time

Operation Monitoring

Start heating function

Begin ultrasonic cleaning

Monitor operation status

Post-processing

Remove cleaned objects

Drain cleaning liquid

Clean equipment inside and out

Maintenance Schedule

Daily: Rinse with water after use

Weekly: Check drainage system

Monthly: Clean transducer surfaces

Quarterly: Complete electrical inspection

Annually: Professional maintenance

Troubleshooting Guide

Symptom

Possible Cause

Solution

No Heating

Heater failure

Contact support

Weak Ultrasound

Transducer issue

Check connection or replace

Temp Inaccurate

Sensor failure

Recalibrate

Water Leakage

Seal damage

Replace seals

Customer Value Proposition of Ultrasonic Cleaning for Industrial Gaskets

Value for Distributors

✓ Complete Product Line: Covers 1.3L-30L full series

✓ Flexible Purchasing: Support mixed model orders

✓ Technical Support: Complete documentation & training

✓ Market Coverage: Meets different customer needs

✓ Profit Optimization: Series products increase sales opportunities

Value for End Users

✓ Precise Selection: Multiple capacities for different needs

✓ Quality Assurance: Unified high-quality standards

✓ Easy Operation: Standardized operation interface

✓ Easy Maintenance: Universal parts and consumables

✓ Upgrade Path: Capacity and power can be upgraded gradually

Quality Control System of Ultrasonic Cleaning for Precision Bearings

Production Standards

Raw Materials: Food-grade 304 stainless steel

Production Process: Automated welding and assembly

Testing Standards: 48-hour aging test for each unit

Packaging Requirements: Export standard packaging

Quality Certifications

Product Certifications: CE, RoHS, ISO9001

Safety Standards: International electrical safety standards

Environmental Compliance: WEEE and REACH compliant

After-sales Service

Warranty Policy: 1 year for whole machine, 2 years for main parts

Technical Support: Multi-language support and training

Spare Parts Supply: Long-term inventory of common parts

Repair Services: Global repair network support

Customization Services of Ultrasonic Cleaning for Industrial Valves

OEM/ODM Options

Brand Customization: Housing logo and color customization

Function Customization: Special control logic development

Accessory Customization: Special baskets and racks

Packaging Customization: Brand packaging design

Small Batch Services

Sample Orders: From 1 unit, fast samples

Mixed Orders: Different models mixed shipment

Trial Order Policy: Discounted trial order prices

Logistics Services

Fast Delivery: Standard 15-20 working days

Global Logistics: FOB, CIF, DDP terms available

Local Support: Local warehouse support in key markets

Why Choose Our Benchtop Series?

Technical Advantages

Full Series 40KHz Technology: Uniform cleaning performance

Modular Design: Easy maintenance and upgrades

Continuous Innovation: Constant improvement based on feedback

Manufacturing Advantages

Scale Production: Significant cost advantages

Quality Consistency: Ensured by automation

Quick Response: Flexible production planning

Service Advantages

Professional Team: 10+ years industry experience

Global Network: Service support in key markets

Continuous Support: Full product lifecycle support

Market Advantages

Mature Products: Long-term market validation

Wide Applicability: Multiple industry applications

Good Reputation: Over 96% customer satisfaction

- Reply within 24 hrs

Get A Quote

Partner with Cleaningsonic to access high-quality ultrasonic cleaning machines that meet the needs of industries like automotive, electronics, and medical equipment. Our OEM/ODM capabilities, flexible small-order support, and global export experience help you expand your market with confidence. Contact us today to explore how we can elevate your distribution business!

Main Product

Compact Ultrasonic Cleaners for Jewelry

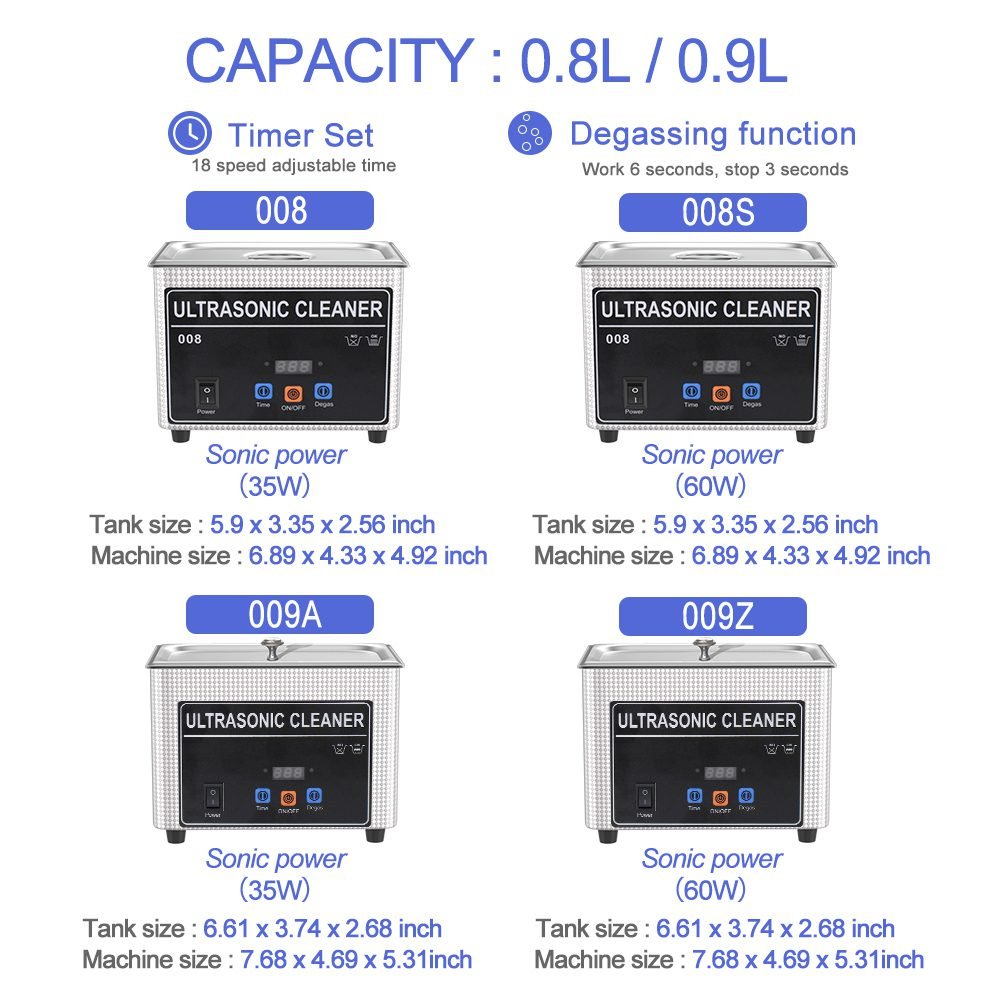

008 Series (0.8L/0.9L)

Heated Ultrasonic Cleaner

009 Series (1.3L)

Ultrasonic Cleaner for Tool Cleaning

010 Series (2L)

Laboratory Medical Cleaning Equipment

020 Series (3.2L)

Professional Grade Cleaning Solutions

030 Series (4.5L)

Industrial Grade Deep Cleaning Equipment

031 Series (6.5L)

Industrial Batch Cleaning System

060 Series(15L)

Industrial Ultrasonic Cleaner

080 Series (22L)

Industrial Ultrasonic Cleaning Machine

100 Series (30L)

Blue Light Ultrasonic Cleaner

CS010 Series(480ML)

Ultrasonic Cleaner for Eyeglass Jewelry

CS020 Series (680ML)

2-in-1 Ultrasonic UV Cleaner

200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Neoclassical Sofa

Model 200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Neoclassical Sofa

Model 200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Hot Tags & Keywords

Primary Keywords:

Benchtop Ultrasonic Cleaner Laboratory Ultrasonic Cleaner Small Ultrasonic Cleaner Industrial Ultrasonic Cleaning Equipment 40KHz Ultrasonic Cleaner

Capacity Keywords:

1.3L Ultrasonic Cleaner 10L Ultrasonic Cleaner 30L Ultrasonic Cleaner Small Benchtop Cleaner Medium Industrial Cleaner

Application Keywords:

Laboratory Cleaning Equipment Electronic Components Cleaner Jewelry Cleaning Equipment Medical Equipment Cleaner Mold Ultrasonic Cleaning

Technical Keywords:

Digital Temperature Control Ultrasonic Heated Ultrasonic Cleaner 40KHz High-frequency Cleaning Sandwich Transducer Intelligent Control Cleaning Equipment

Commercial Keywords:

Ultrasonic Cleaner Full Series OEM Cleaning Equipment Customization Small Batch Cleaner Purchase Industrial Equipment Distribution Global Export Ultrasonic Equipment

.png)

.png)

.png)