PRODUCT

Contact withus for any advice

Need help? Talk to an expert

+86 19068026712

Basic Series Ultrasonic Cleaner | Mechanical Knob Control | 1.3L-30L Economy - Cleaningsonic

Cleaningsonic Basic Series ultrasonic cleaner, mechanical knob control, simple & reliable operation, 1.3L-30L multiple capacities, 40KHz industrial transducers. Ideal for daily cleaning needs in homes, labs, repair shops. Top choice for value.

ST Series Adjustable Power Ultrasonic Cleaner

- Ultrasonic+Temperature+Time

- Capacity: 3.2L-30L

- Sonice Power: 120W-900W

- Frequency: 40KHz

- Temp Range:0-80°C

- Timer Range: 0-30 min

Basic Series Ultrasonic Cleaner - Mechanical Knob Operation | Simple & Reliable | 1.3L-30L Full Range | Economical & Practical Choice

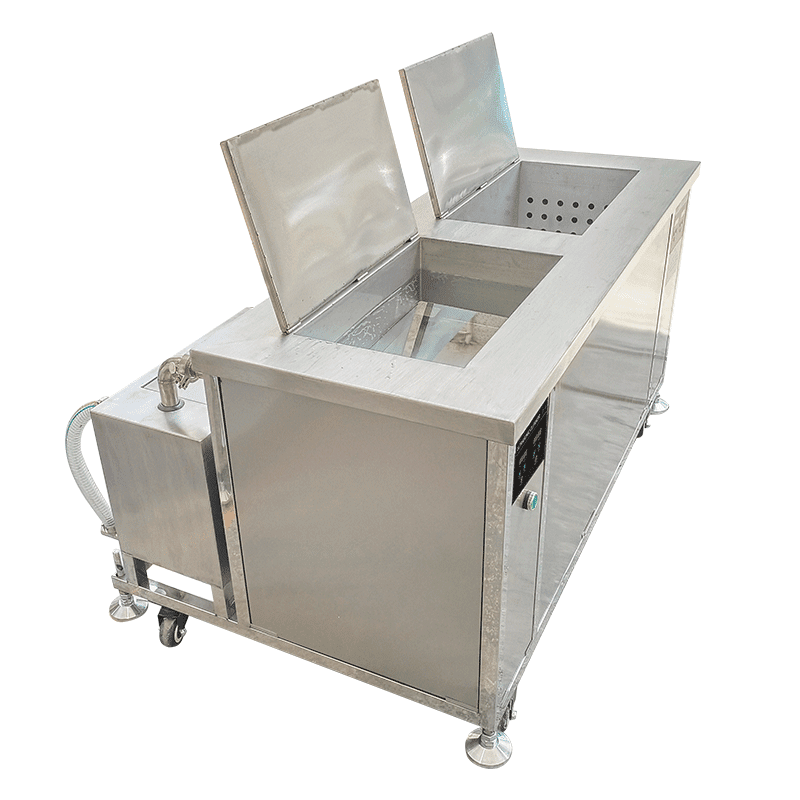

Product Overview of Tabletop Ultrasonic Cleaning Station

Basic Series Ultrasonic Cleaner – Reliable & Durable Entry-Level Cleaning Solution

The Cleaningsonic Basic Series ultrasonic cleaner is designed for users who prioritize simple operation, reliable performance, and ultimate value for money. The entire series adopts classic mechanical knob controls, combined with 40KHz industrial-grade sandwich piezoelectric transducers. It offers 9 capacity specifications from 1.3L to 30L, with power ranging from 60W to 900W, meeting the basic cleaning needs of households, small studios, repair shops, and budget-conscious businesses.

As a professional industrial cleaning equipment manufacturer, we understand the importance of simplicity and reliability for daily use. The Basic Series eschews complex digital control systems, returning to the intuitive operation of mechanical knobs, ensuring stable operation in various environments. Whether cleaning glasses and jewelry, hardware tools, or laboratory glassware, the Basic Series delivers dependable cleaning performance.

Product Series Overview of Ultrasonic Nail Tool Cleaner

Basic Series Core Features

Operation Method: Full mechanical knob control, no complex electronic parts

Core Component: 40KHz sandwich piezoelectric transducer, 40,000Hz vibration frequency

Control Functions: Temperature adjustable 0-80°C, Time settable 0-99 minutes

Structural Design: 304 stainless steel tank, durable and easy to clean

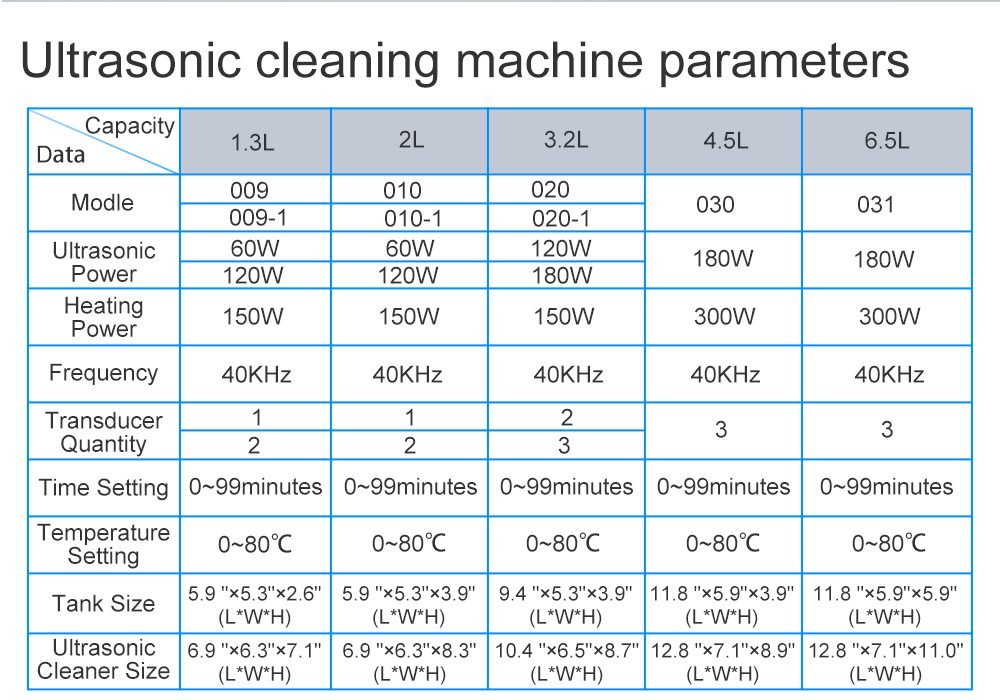

Capacity & Power Configuration

Capacity

Model Series

Ultrasonic Power

Heating Power

Transducer Qty

Application Scenarios

1.3L

009/009-1

60W/120W

150W

1-2 units

Personal Household, Jewelry Store

2L

010/010-1

60W/120W

150W

1-2 units

Dental Clinic, Eyeglass Store

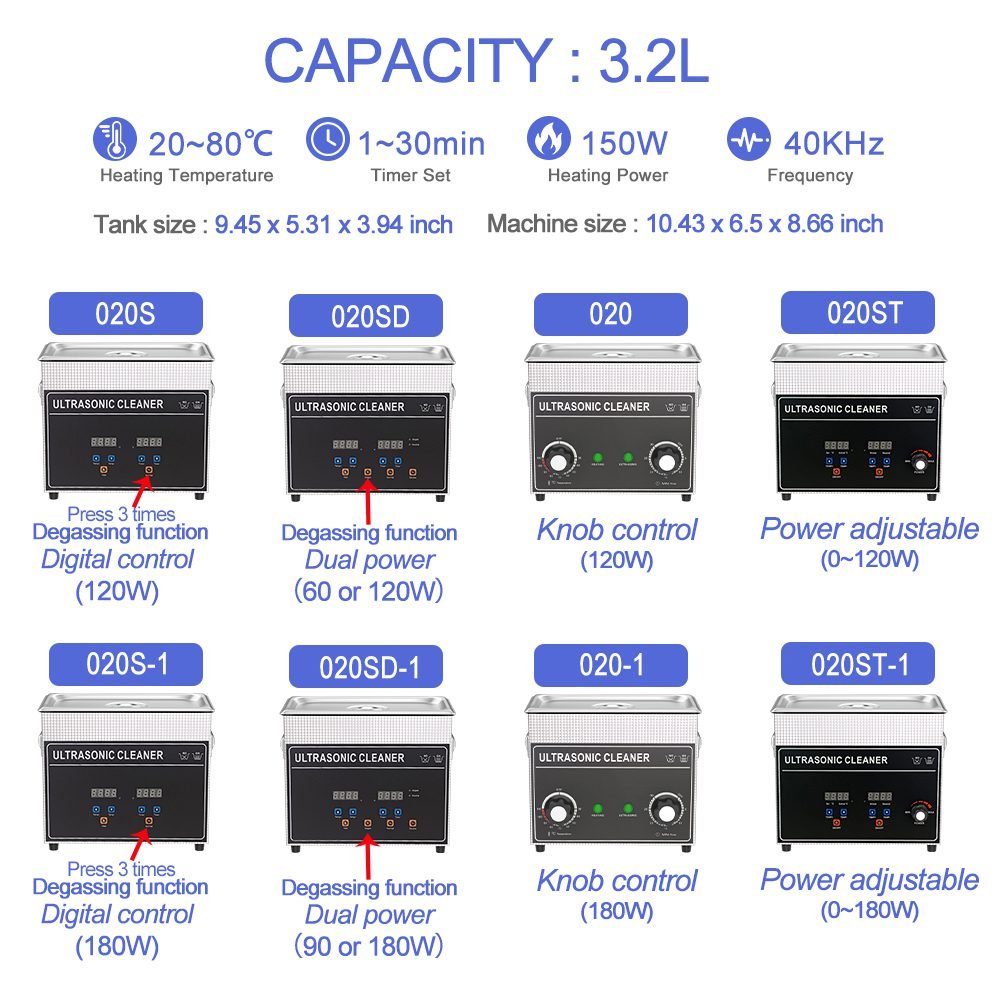

3.2L

020/020-1

120W/180W

150W

2-3 units

Electronics Repair, Small Studio

4.5L

030

180W

300W

3 units

Laboratory, Hardware Store

6.5L

031

180W

300W

3 units

Small Auto Parts Cleaning

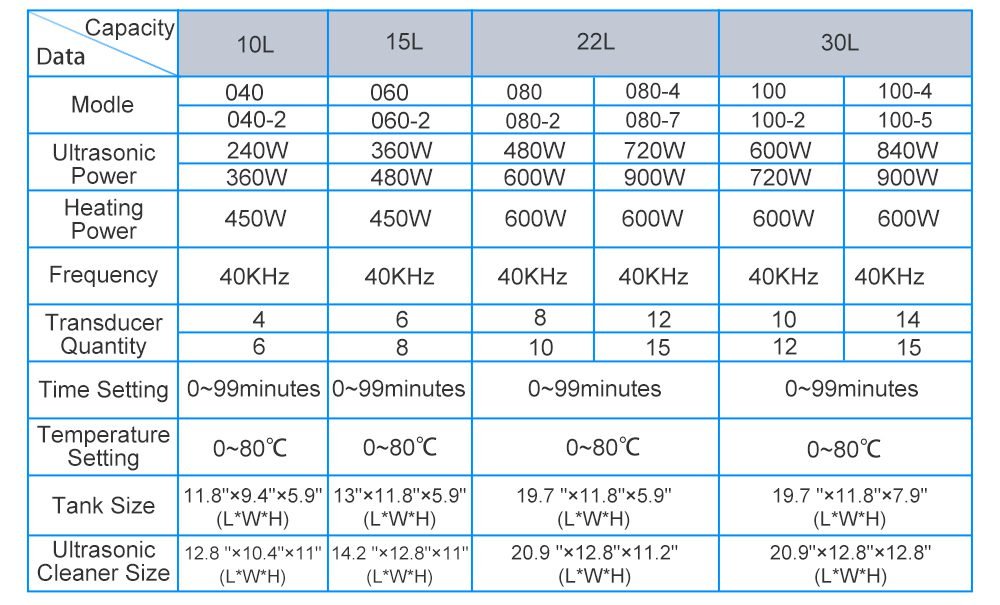

10L

040 Series

240W-360W

450W

4-6 units

Small Workshop, Service Station

15L

060 Series

360W-480W

450W

6-8 units

Mold Pre-treatment, Tool Cleaning

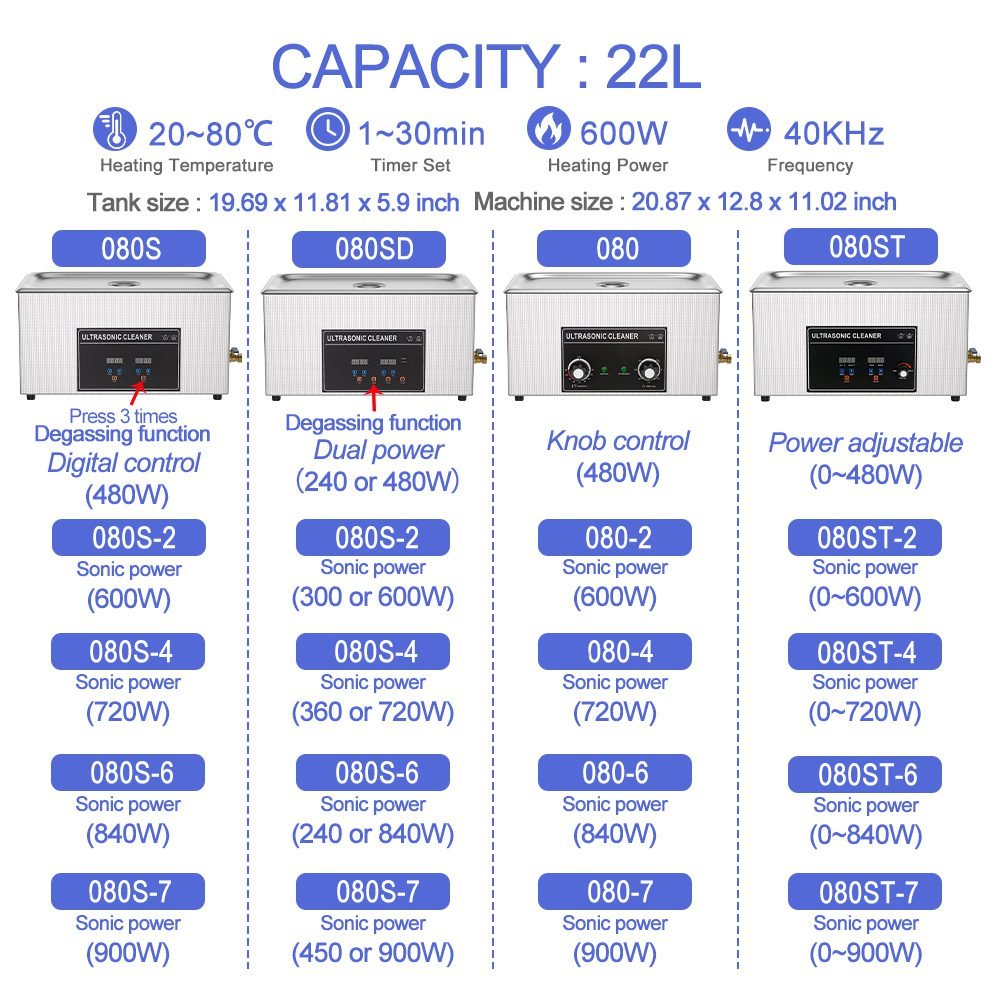

22L

080 Series

480W-900W

600W

8-15 units

Industrial Maintenance, Batch Cleaning

30L

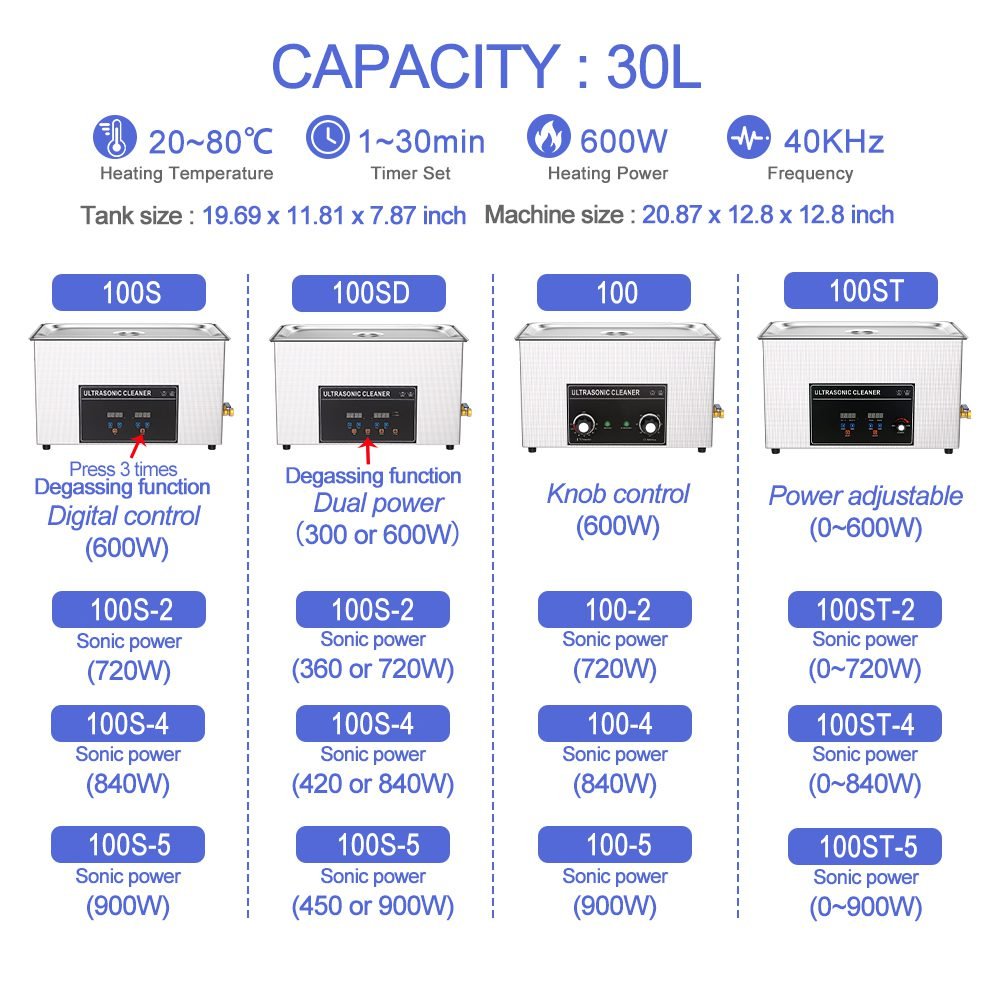

100 Series

600W-900W

600W

10-15 units

Factory Primary Cleaning Process

Core Product Advantages of Ultrasonic Eyewear Cleaning Station

Mechanical Knob Operation Advantages

Intuitive Operation: Temperature knob with scale (0-80°C), Time knob with scale (0-99 minutes)

Durable & Reliable: No electronic screen, avoids LCD damage risk

Strong Environmental Adaptability: Suitable for high temp, high humidity, dusty environments

Low Learning Curve: Operable without a manual

Industrial-grade Core Components

Sandwich Piezoelectric Transducer:

40,000Hz vibration frequency, delicate cleaning

Sandwich structure, high energy conversion efficiency

Industrial-grade design, long-life stable operation

Mechanical Timer: Mechanical gear drive, reliable accuracy

Bimetal Thermostat: Mechanical temperature control, quick response

Sturdy & Durable Structure

304 Stainless Steel Inner Tank: Unified standard across the series

Mechanical Drain Valve: Simple structure, not prone to clogging

Splash-proof Design: Knob panel prevents liquid ingress

Reinforced Structure: Thickened tank, no deformation during long-term use

Ultimate Value for Money

Component Cost Optimization: Eliminates digital displays and control chips

Low Maintenance Cost: Mechanical parts are simple and cheap to repair/replace

Low Operating Cost: Reasonable power consumption, low running expenses

Fast ROI: Affordable price, quick cost recovery

Detailed Technical Specifications of Sonic Cleaner for Rings, Glasses, Jewelry, Dentures White

Small Series Parameters (1.3L-6.5L)

Medium Series Parameters (10L-30L)

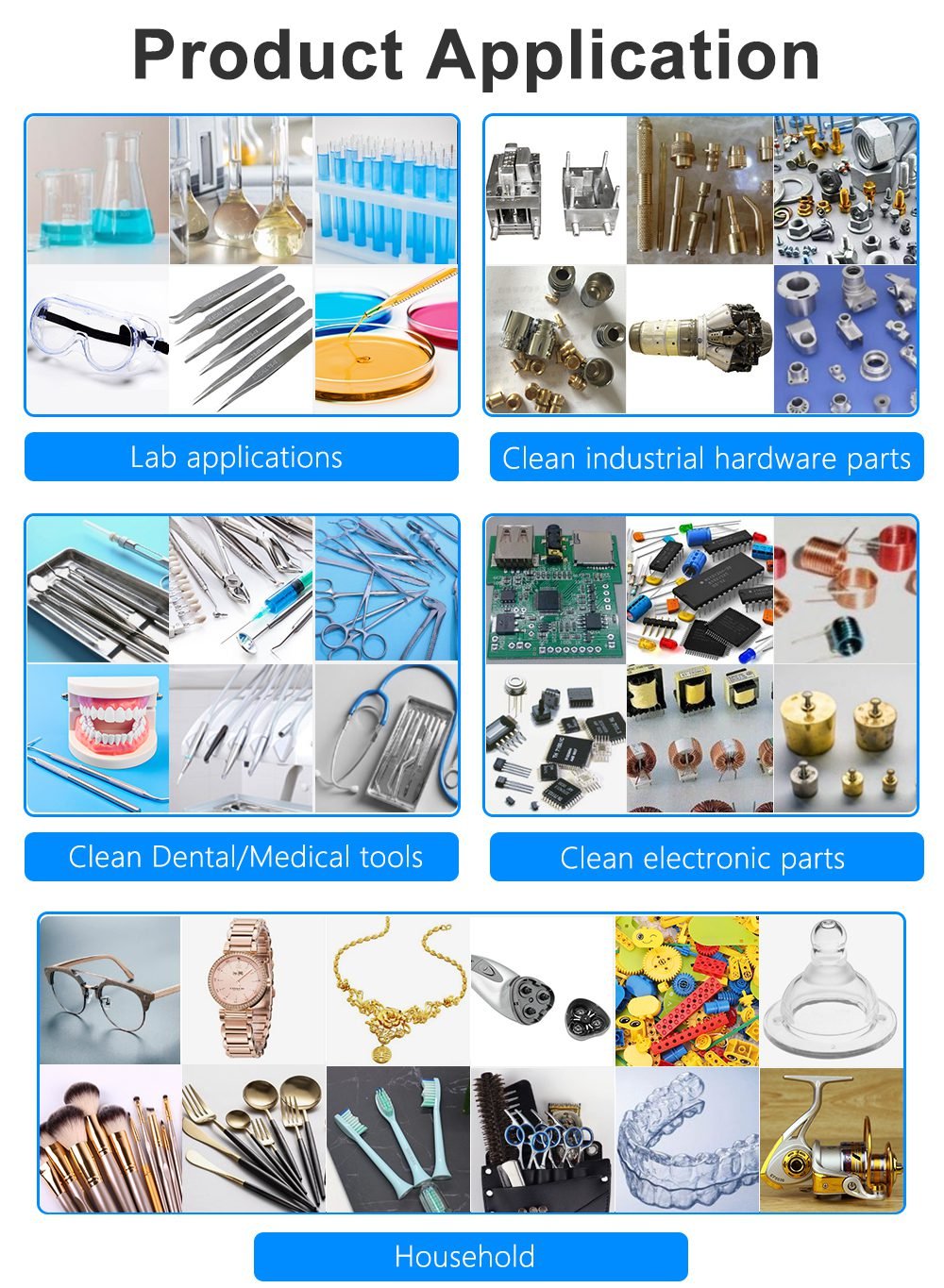

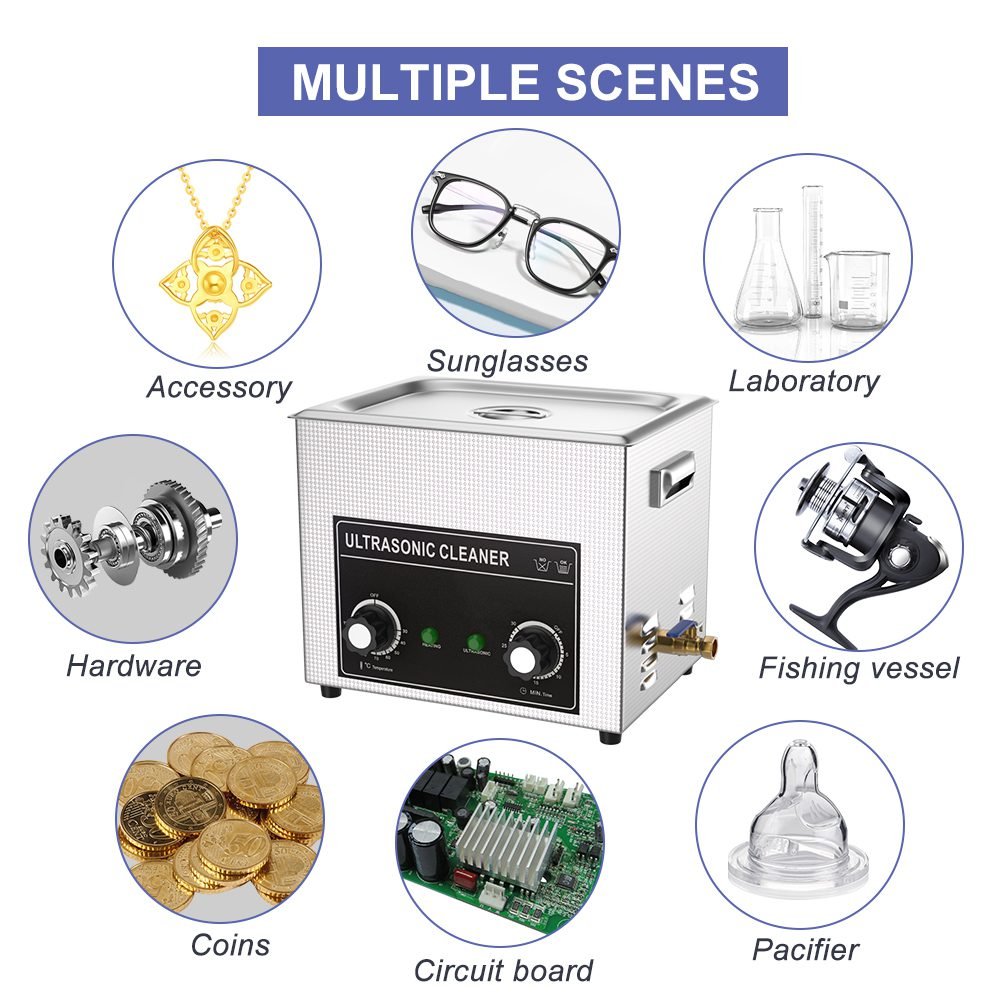

Application Scenarios of Ultrasonic Retainer Cleaner Machine

Household Daily Cleaning

Cleaning Items: Glasses, jewelry, dentures, razors, pacifiers, coins

Recommended Models: 1.3L-3.2L Basic Series

Cleaning Effect: Removes grease, stains, bacteria

Usage Frequency: 1-2 times per week

Economic Benefit: Replaces professional cleaning services, saves expenses

Small Commercial Applications

Eyeglass Store: Cleaning frames, sunglasses

Jewelry Store: Cleaning gold/silver jewelry, gemstones

Dental Clinic: Cleaning dental instruments, dentures

Repair Shop: Cleaning small parts, tools

Recommended Models: 2L-6.5L Basic Series

Education & Research Institutions

School Labs: Cleaning labware

Research Units: Sample pre-treatment cleaning

Training Centers: Teaching/demonstration equipment

Recommended Models: 4.5L-10L Basic Series

Advantage: Simple operation, easy for students to learn and use

Industrial Primary Cleaning

Pre-treatment Process: Initial cleaning before precision cleaning

Tool Maintenance: Daily cleaning and upkeep of repair tools

Small Batch Production: Cleaning needs of small manufacturers

Recommended Models: 10L-30L Basic Series

Cost Advantage: Low equipment investment, low maintenance cost

Maintenance of Ultrasonic Dentures Cleaner for Night Guards, Braces, Aligner, Toothbrush, Jewelry and More

Daily Maintenance

After Each Use: Drain cleaning solution, rinse tank with clean water

Weekly Cleaning: Wipe knobs and panel with a soft cloth

Monthly Check: Check if knobs rotate smoothly

Drainage System: Clean drain valve regularly to prevent clogging

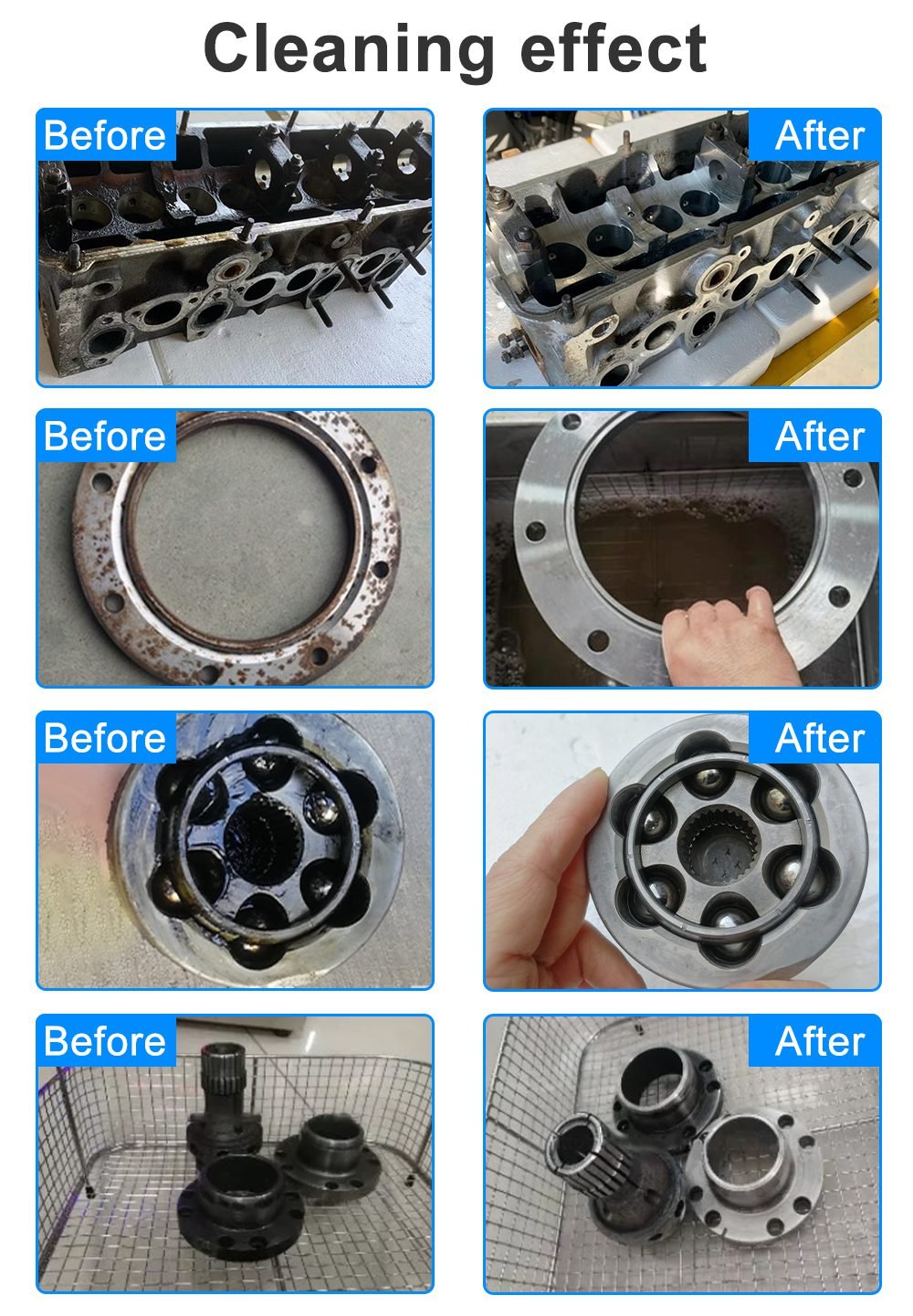

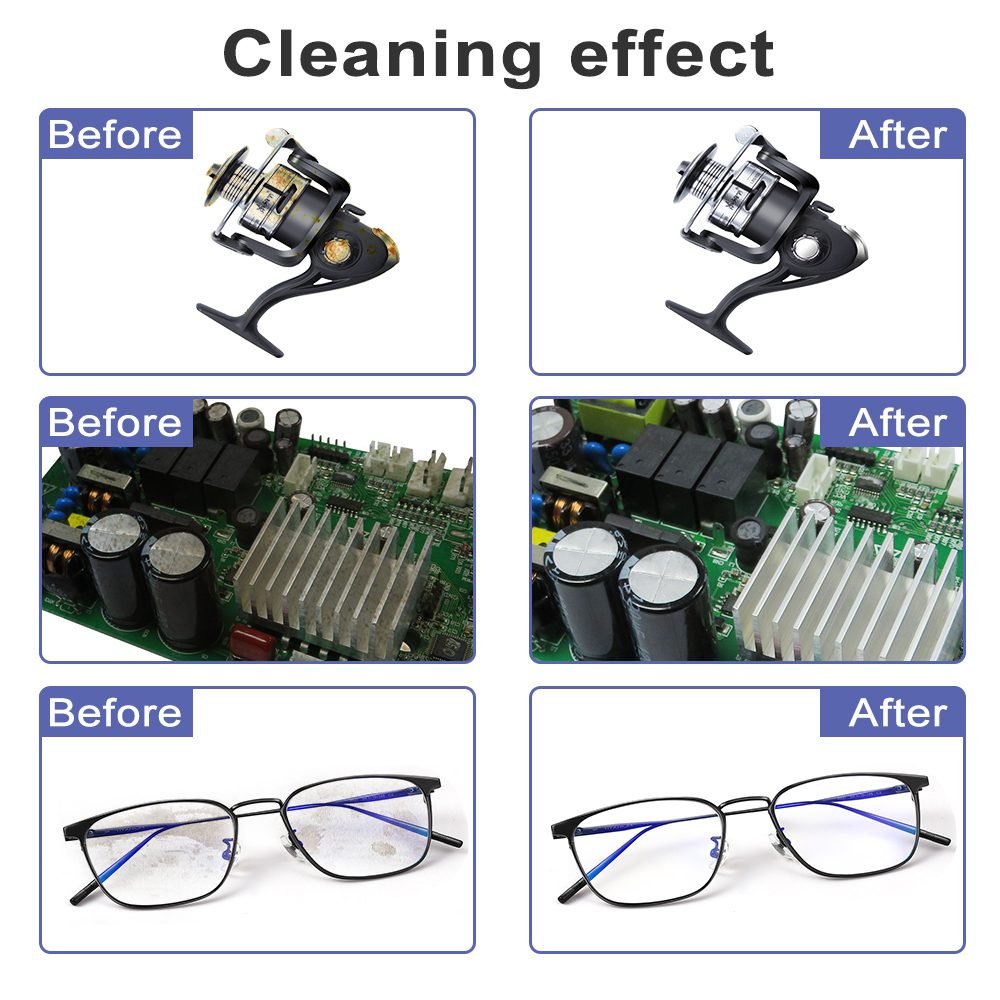

7.Cleaning Effect Comparison of Industry Cleaner Washing Tank Engine Block Parts DPF Bath Sonic Equipment

Real Cleaning Cases

Engine Carburetor Cleaning

Before: Heavy grease, clogged channels

Power Setting: 100% Full Power

Temp/Time: 75°C, 25 minutes

After: Grease completely removed, channels clear

Precision Watch Movement

Before: Old lubricant solidified, poor operation

Power Setting: 40% Low Power

Temp/Time: 40°C, 8 minutes

After: Grease removed, parts undamaged

Electronic Soldering Fixture

Before: Flux buildup affecting accuracy

Power Setting: 60% Medium Power

Temp/Time: 50°C, 12 minutes

After: Flux completely cleared, fixture like new

Troubleshooting

Symptom

Possible Cause

Solution

No Heating

Poor contact of heating switch

Check switch connection

Ultrasonic Not Working

Ultrasonic switch failure

Check switch or replace

Temp Inaccurate

Thermostat needs calibration

Contact professional for calibration

Water Leakage

Drain valve seal aging

Replace seal

Maintenance Cost Advantage

Mechanical Parts: Knobs, switches, etc., are low-cost

Self-Repair: Users can replace simple parts themselves

Long Lifespan: Mechanical structure designed for 10+ years

Abundant Spare Parts: Standard mechanical parts are readily available

Value for Money Analysis

Investment Cost Comparison

Item

Basic Series

Digital Series

Advantage Comparison

Equipment Price

30-50% lower

Standard Price

Lower initial investment

Maintenance Cost

Very Low

Medium

Lower long-term operating cost

Training Cost

Almost Zero

Training Required

Quick to get started

Part Replacement

Cheap & Readily Available

Specialized parts more expensive

Economical repairs

Target User Analysis

Budget-Conscious Users: Start-ups, individual businesses, households

Simple Need Users: Require only basic cleaning functions

Harsh Environment Users: Dusty, humid, high-temperature-variation workplaces

Backup Equipment Need: As a backup for digital equipment

Return on Investment Period

Commercial Users: Typically recover investment in 3-6 months

Industrial Users: Recover investment in 2-4 months

Household Users: 6-12 months equivalent to professional cleaning service fees

Model Selection Guide of Ultrasonic Retainer Cleaner Machine

Choose by Usage Frequency

Low Frequency (A few times per month):

├── Household/Personal: 1.3L-2L

├── Small Shop: 2L-3.2L

└── Occasional Cleaning: 3.2L-4.5L

Medium Frequency (A few times per week):

├── Small Studio: 4.5L-6.5L

├── Repair Shop: 6.5L-10L

└── Educational Institution: 10L-15L

High Frequency (Daily Use):

├── Small Batch Production: 15L-22L

├── Industrial Pre-treatment: 22L-30L

└── Multi-process Cleaning: 30L

Choose by Cleaning Object

Small Objects:

├── Jewelry: 1.3L-2L

├── Glasses/Dentures: 2L-3.2L

├── Electronic Components: 3.2L-4.5L

└── Labware: 4.5L-6.5L

Medium Objects:

├── Hardware Tools: 6.5L-10L

├── Automotive Parts: 10L-15L

└── Small Molds: 15L-22L

Large Objects:

├── Mechanical Parts: 22L-30L

└── Batch Cleaning: 30L

Success Cases of Retainer Cleaner Machine for Dentures, Mouth Guards, Braces, Toothbrush Heads, Jewelry

Household User Case

User: Mr. Zhang, Photography Enthusiast

Model Used: 020 Basic (3.2L)

Cleaning Items: Camera lenses, filters, small accessories

Feedback: “Simple to operate, even my child can use it. Cleans very well, removes fingerprints and grease from lenses.”

Economic Benefit: Saves professional cleaning fees, approx. 800 CNY/year

Commercial User Case

User: Ms. Li, Eyeglass Store Owner

Model Used: 010-1 Basic (2L High Power)

Cleaning Items: Customer glasses, sunglasses

Business Value: “Offering free glasses cleaning increases customer loyalty. The equipment is cheap, paid for itself in three months.”

Extended Application: Also cleans jewelry, adding a service item

Industrial User Case

User: Mr. Wang, Machining Factory

Model Used: 080-4 Basic (22L 720W)

Cleaning Process: Degreasing before precision machining

Production Efficiency: “Cleans three batches daily, replaced manual wiping, efficiency increased 5 times.”

Cost Savings: Saved two cleaners, annual labor cost saving 80,000 CNY

Quality Assurance of Ultrasonic Cleaner with Digital Timer & Heater

Manufacturing Standards

Material Standards: Food-grade 304 stainless steel

Assembly Process: Manual fine assembly, each unit inspected

Testing Procedure: 48-hour aging test, 100% functional test

Packaging Standard: Reinforced packaging suitable for long-distance shipping

Performance Guarantee

Ultrasonic Intensity: Ensured to meet rated power

Temperature Accuracy: Mechanical thermostat accuracy ±3°C

Timer Accuracy: Mechanical timer error <2%

Structural Strength: Tank load-bearing test ensures no deformation

Service Support

Warranty Policy: 1-year warranty for the whole machine

Technical Support: Phone and online technical support

Repair Service: Authorized repair points nationwide

Spare Parts Supply: Long-term supply of standard mechanical parts

Why Choose the Basic Series?

Reliability Advantages

Mechanical Structure: No complex electronics, low failure rate

Environmental Adaptation: Suitable for various working environments

Long-term Stability: Long design life, slow performance degradation

Easy Repair: Simple structure, easy maintenance

Economic Advantages

Price Advantage: Most competitive price among similar products

Operating Cost: Reasonable energy consumption, low running cost

Maintenance Cost: Cheap parts, low repair costs

Investment Efficiency: Fast payback, low investment risk

Practicality Advantages

Simple Operation: No training needed, ready to use

Practical Functions: Meets 90% of basic cleaning needs

Robust & Durable: Can withstand a degree of misuse

Strong Versatility: Suitable for multiple industries and applications

- Reply within 24 hrs

Get A Quote

Partner with Cleaningsonic to access high-quality ultrasonic cleaning machines that meet the needs of industries like automotive, electronics, and medical equipment. Our OEM/ODM capabilities, flexible small-order support, and global export experience help you expand your market with confidence. Contact us today to explore how we can elevate your distribution business!

Main Product

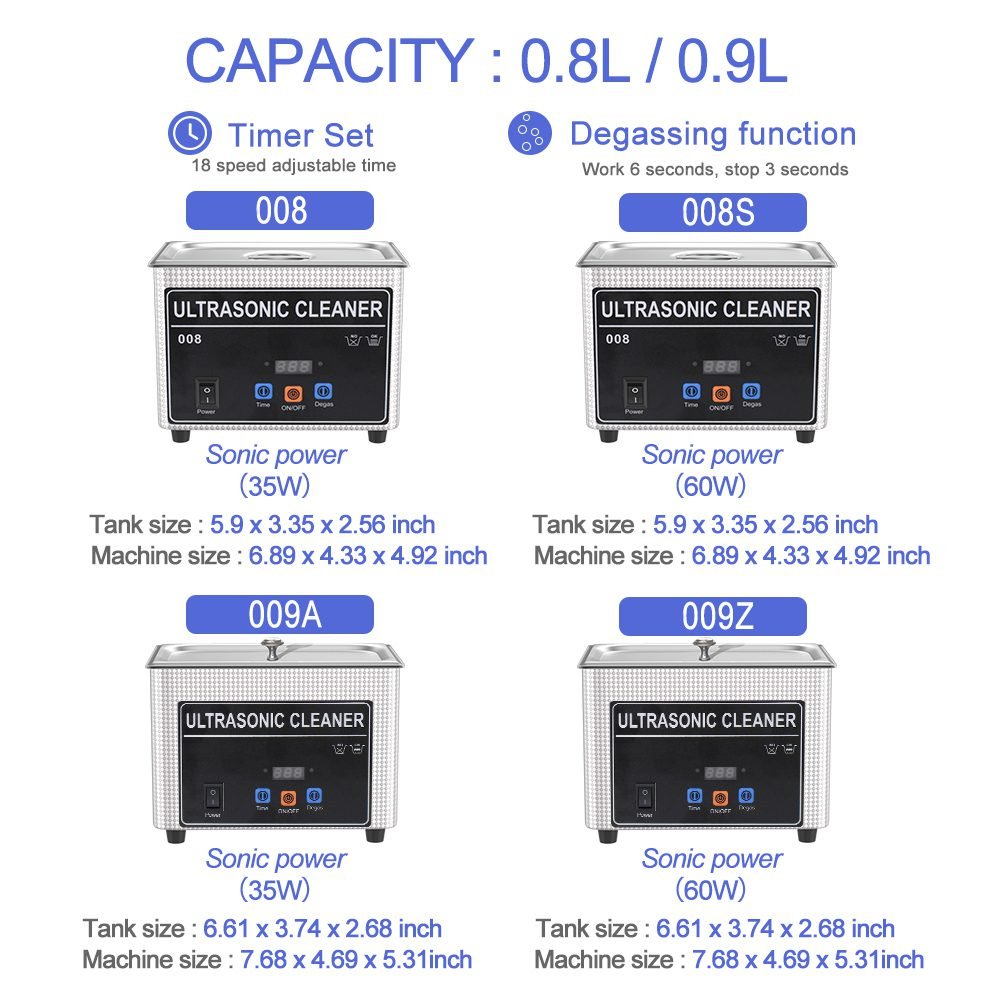

Compact Ultrasonic Cleaners for Jewelry

008 Series (0.8L/0.9L)

Heated Ultrasonic Cleaner

009 Series (1.3L)

Ultrasonic Cleaner for Tool Cleaning

010 Series (2L)

Laboratory Medical Cleaning Equipment

020 Series (3.2L)

Professional Grade Cleaning Solutions

030 Series (4.5L)

Industrial Grade Deep Cleaning Equipment

031 Series (6.5L)

Industrial Batch Cleaning System

060 Series(15L)

Industrial Ultrasonic Cleaner

080 Series (22L)

Industrial Ultrasonic Cleaning Machine

100 Series (30L)

Blue Light Ultrasonic Cleaner

CS010 Series(480ML)

Ultrasonic Cleaner for Eyeglass Jewelry

CS020 Series (680ML)

2-in-1 Ultrasonic UV Cleaner

200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Neoclassical Sofa

Model 200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Neoclassical Sofa

Model 200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Hot Tags & Keywords

Core Feature Keywords:

Mechanical Knob Ultrasonic Cleaner Basic Ultrasonic Cleaner Economical Cleaning Equipment Entry-level Ultrasonic Cleaner Simple Operation Cleaner

Technical Parameter Keywords:

40KHz Industrial Transducer Mechanical Timer Control Knob Temperature Adjustment 304 Stainless Steel Tank Sandwich Piezoelectric Transducer

Application Scenario Keywords:

Home Ultrasonic Cleaner Eyeglass Store Cleaning Equipment Repair Shop Cleaner Laboratory Basic Cleaning Small Industrial Cleaning

Value Proposition Keywords:

High Value for Money Cleaner Economical & Practical Cleaning Equipment Low Maintenance Cost Cleaner Robust & Durable Cleaning Equipment First Choice for Entry-level

Capacity Specification Keywords:

Small Ultrasonic Cleaner Benchtop Cleaning Equipment Basic Model Medium Economy Cleaner Large Basic Cleaning Equipment Multiple Capacity Economy Choice

.png)

.png)

.png)