PRODUCT

Contact withus for any advice

Need help? Talk to an expert

+86 19068026712

ST Series Adjustable Power Ultrasonic Cleaner | 120W-900W Stepless Adjustable | 3.2L-30L - Cleaningsonic

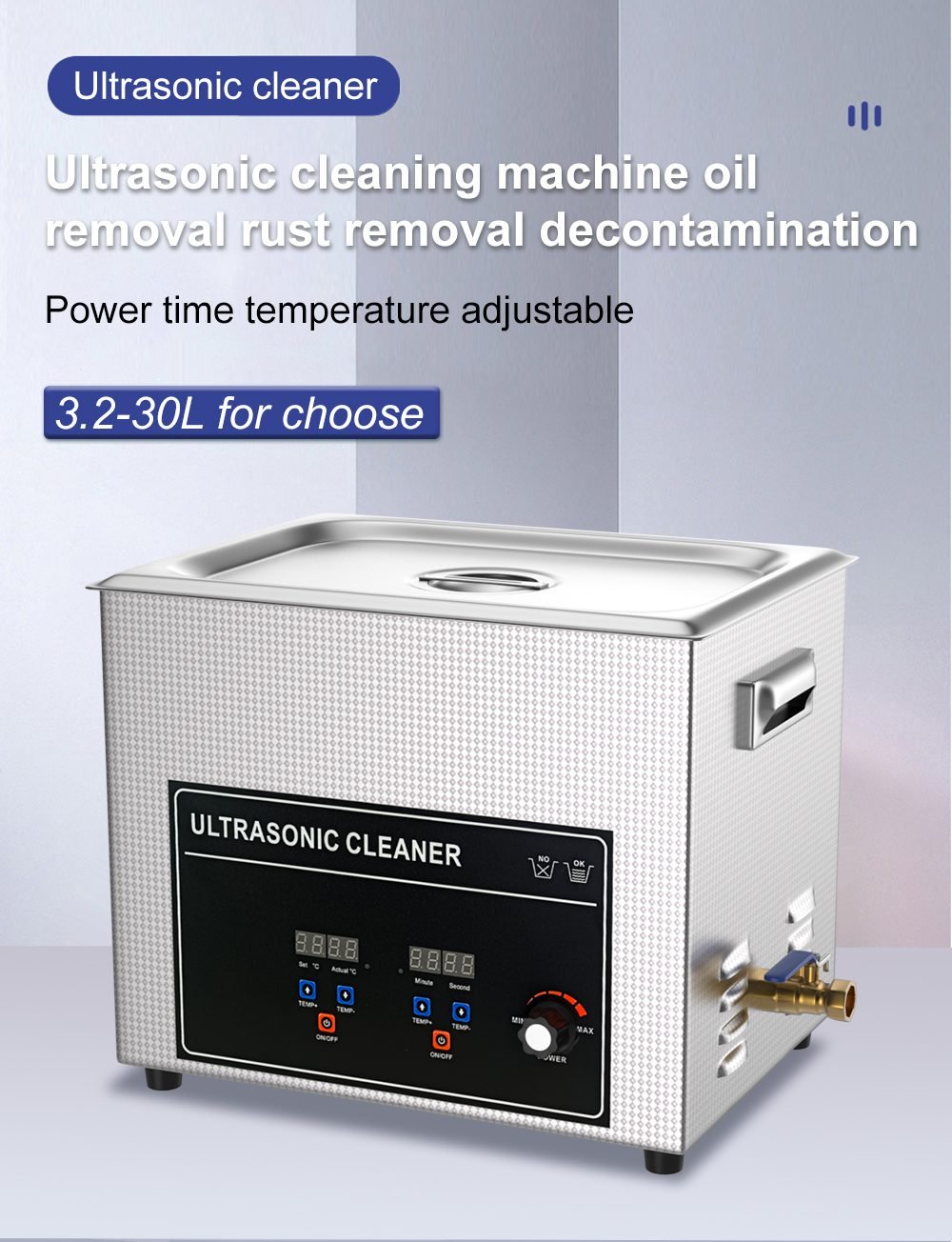

Cleaningsonic ST Series ultrasonic cleaner, power adjustable 0-100%, 40KHz industrial transducers, digital touch control, 3.2L-30L capacity. Suitable for various cleaning needs from precision electronics to stubborn grease. One machine for multiple uses.

ST Series Adjustable Power Ultrasonic Cleaner

- Ultrasonic+Temperature+Time

- Capacity: 3.2L-30L

- Sonice Power: 120W-900W

- Frequency: 40KHz

- Temp Range:0-80°C

- Timer Range: 0-30 min

ST Series Intelligent Adjustable Power Ultrasonic Cleaner - 0-100% Stepless Adjustment | Impact Force up to 800Pa | 3.2L-30L Full Range

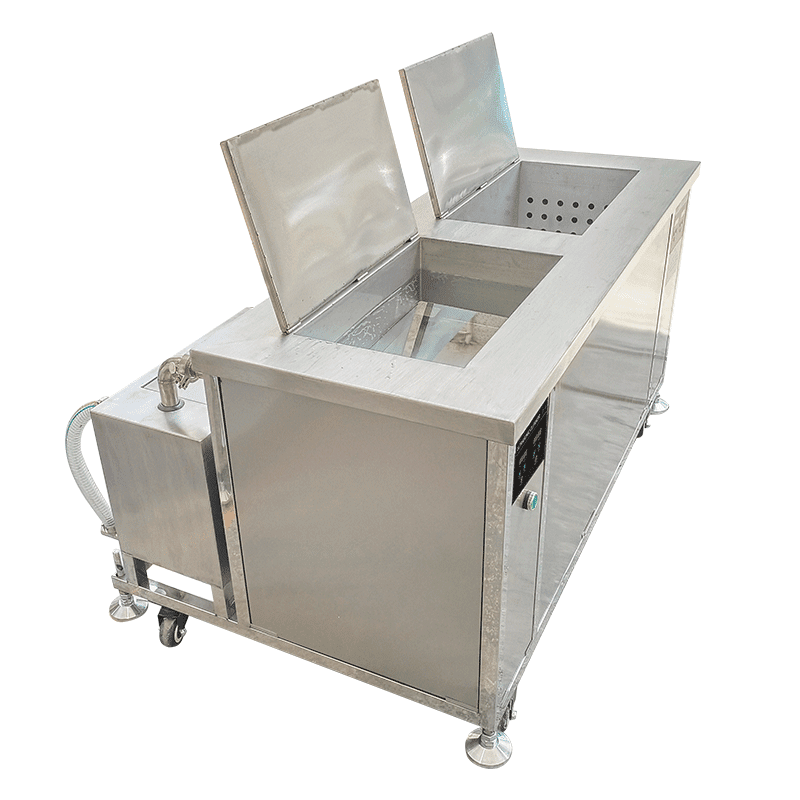

Product Overview of Large Capacity Ultrasonic Cleaner

ST Series Adjustable Power Ultrasonic Cleaner – Intelligent Solution for Diverse Cleaning Needs

The Cleaningsonic ST Series ultrasonic cleaner is an innovative product that pioneers stepless power adjustment as a standard feature across the entire series. Covering 7 standard capacities from 3.2L to 30L, it offers an adjustable power range from 120W to 900W, combined with 40KHz industrial-grade high-power transducers (60W per transducer, 800Pa impact force) and an intelligent digital control system. This enables versatile cleaning from the most delicate electronic components to the most stubborn industrial grease.

As a professional industrial cleaning equipment manufacturer, we deeply understand the varying cleaning intensity requirements for different workpieces. Through innovative stepless power adjustment technology, the ST Series allows one machine to adapt to multiple scenarios: gentle cleaning for jewelry and eyewear, standard cleaning for electronic PCBs, and powerful cleaning for hardware and molds, truly achieving “one machine, multiple uses, intelligent adaptation”.

Product Series Overview of Ultrasonic Cleaner

ST Series Core Features

Full Series Standard: 0-100% stepless power adjustment function

Powerful Core: 40KHz industrial transducers, 60W each, 800Pa impact force

Intelligent Control: Digital touch control + Independent temperature/time adjustment

Professional Quality: SUS304 stainless steel tank + Industrial-grade structural design

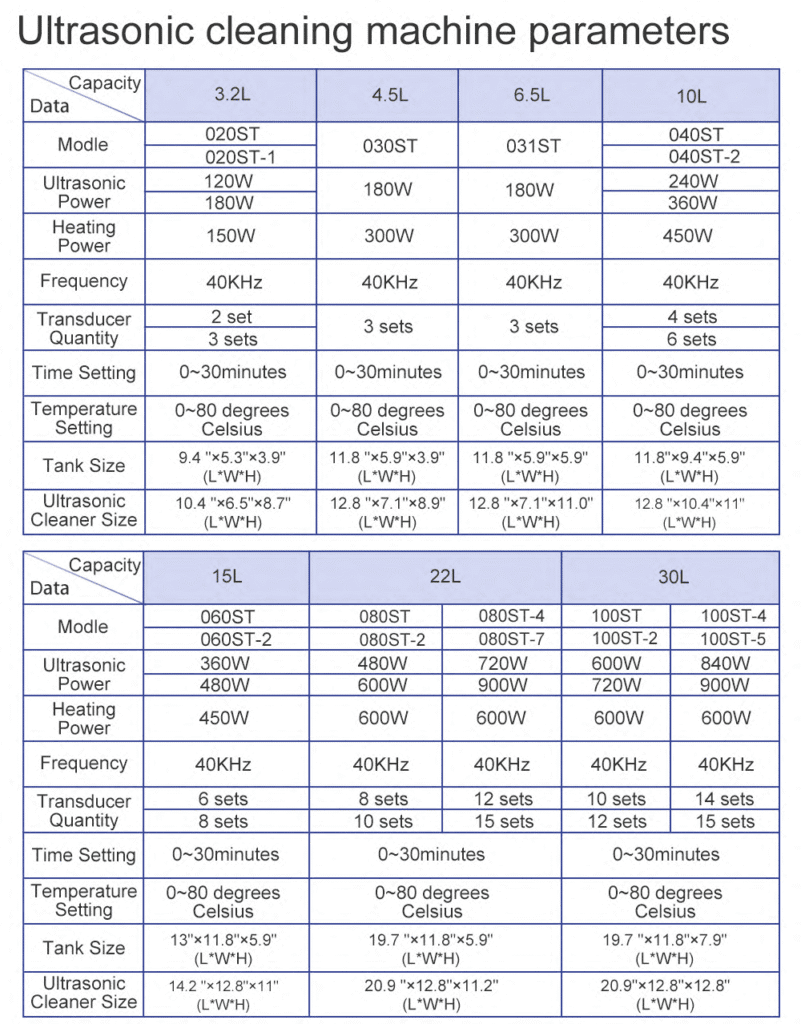

Capacity & Power Matrix

Capacity

Model Series

Adjustable Power Range

Heating Power

Transducer Qty

Typical Applications

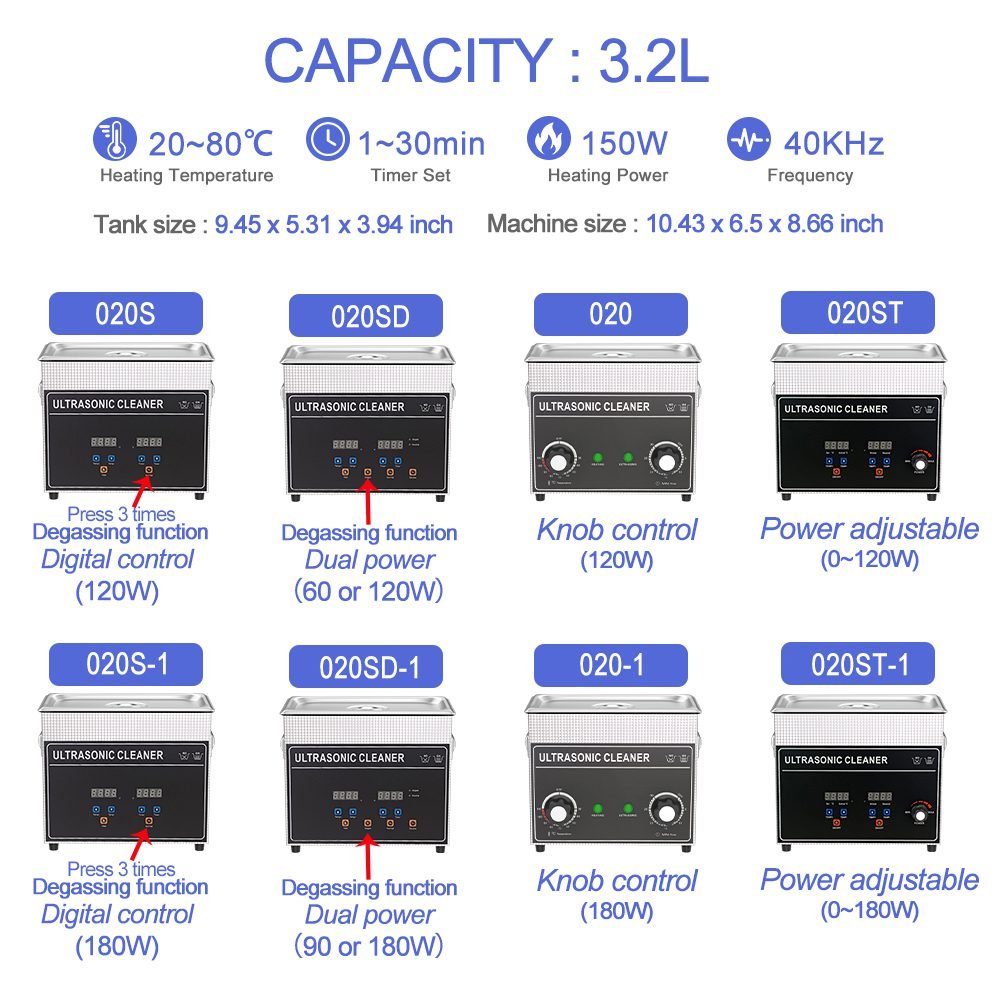

3.2L

020ST/020ST-1

0-180W adjustable

150W

2-3 units

Electronic components,

4.5L

030ST

0-180W adjustable

300W

3 units

Laboratory glassware, Small tools

6.5L

031ST

0-180W adjustable

300W

3 units

Dental instruments, Precision parts

10L

040ST/040ST-2

0-360W adjustable

450W

4-6 units

Small/medium batch production

15L

060ST/060ST-2

0-480W adjustable

450W

6-8 units

Hardware tools, Automotive parts

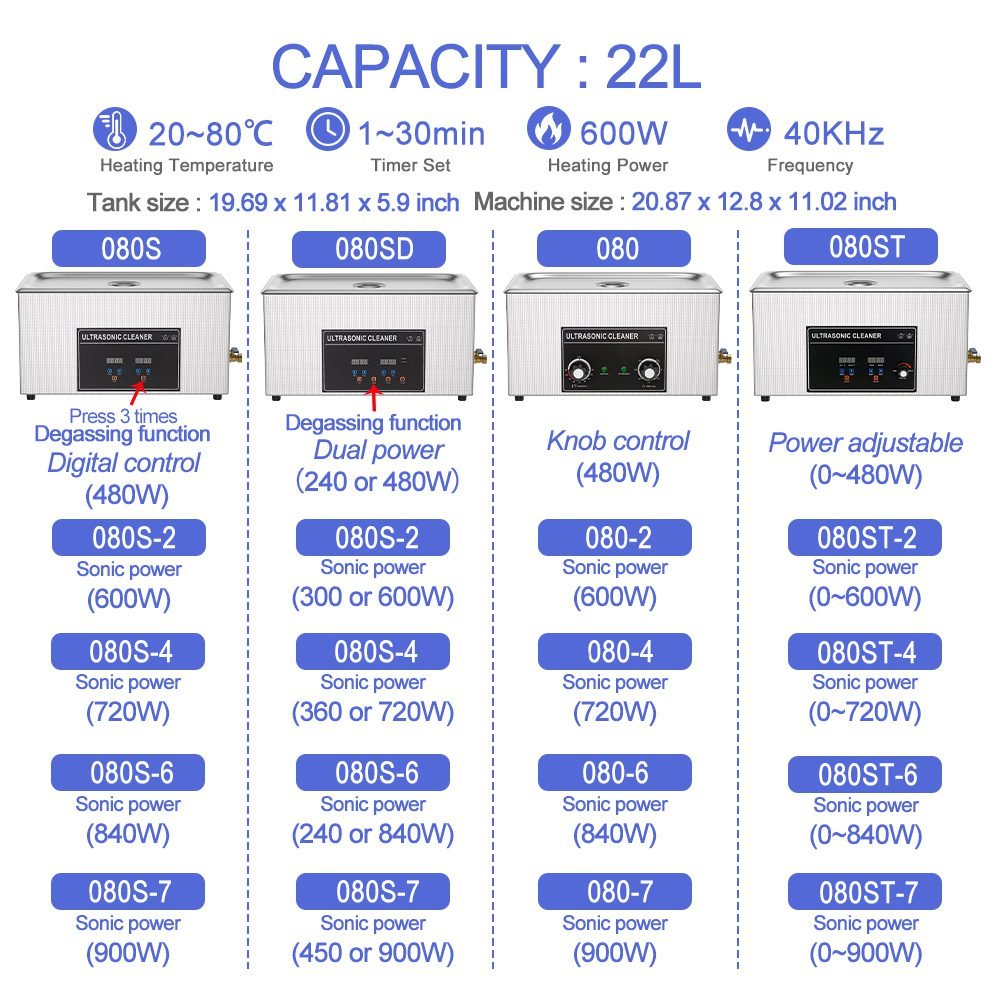

22L

080ST Series

0-900W adjustable

600W

8-15 units

Mold cleaning, Industrial maintenance

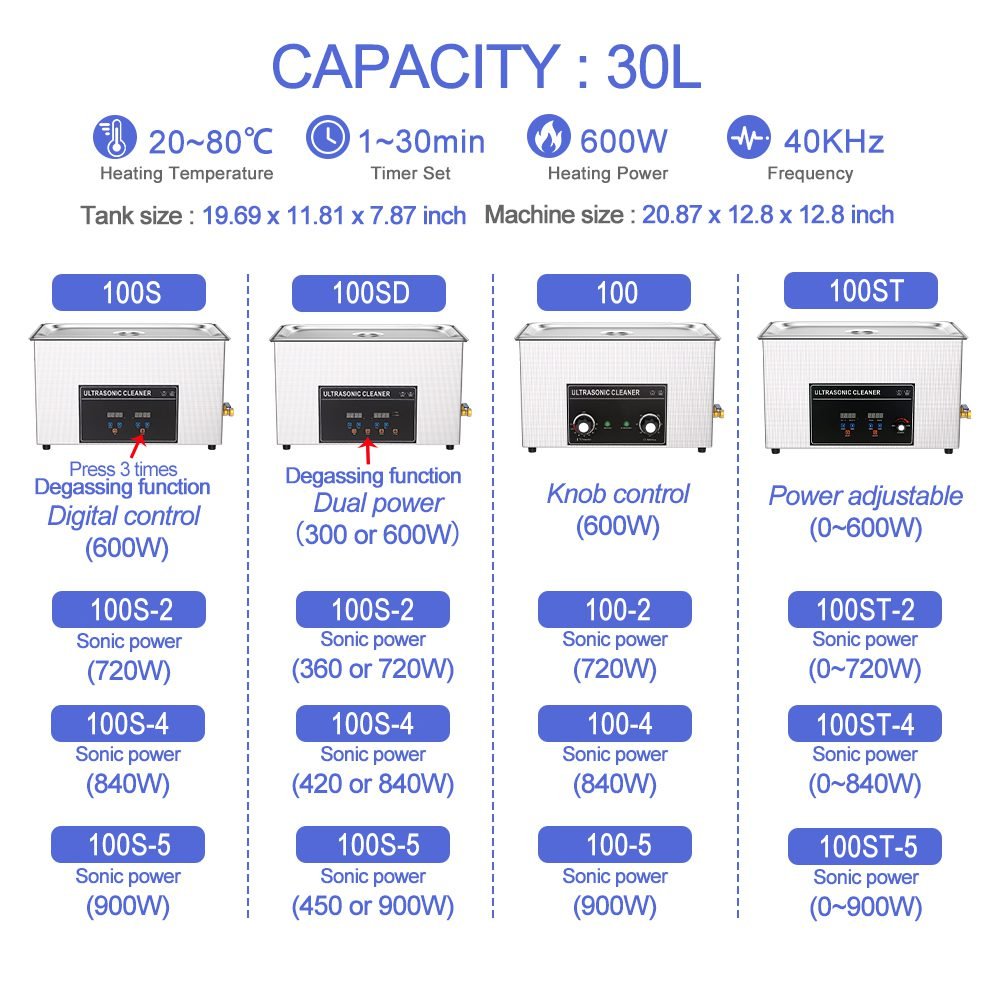

30L

100ST Series

0-900W adjustable

600W

10-15 units

Industrial batch cleaning

Core Technical Highlights of Power Adjustable Ultrasonic Parts Cleaner for Cleaning Carburetor, Metal Engine Parts, Gun, Oil Filter, Bike Chain, Gear, Eyewear, Watch, Jewelry

Stepless Power Adjustment Technology

Adjustment Range: 0-100% continuously adjustable, stepless

Control Precision: 1%-level adjustment precision for fine control

Real-time Display: Power adjustment knob with MIN-MAX scale indication

Application Value:

MIN Setting (Low Power): Protects delicate, fragile workpieces

Mid Settings: Standard cleaning applications

MAX Setting (Full Power): Handles stubborn, heavy contamination

High-Power Industrial Transducers

Single Transducer Specs: 60W power, 40KHz frequency, 800Pa impact force

Technical Advantages:

High energy density for powerful cleaning

Long-life design for excellent stability

Uniform arrangement for even sound field distribution

Power Configuration: Modular configuration from 2 to 15 units

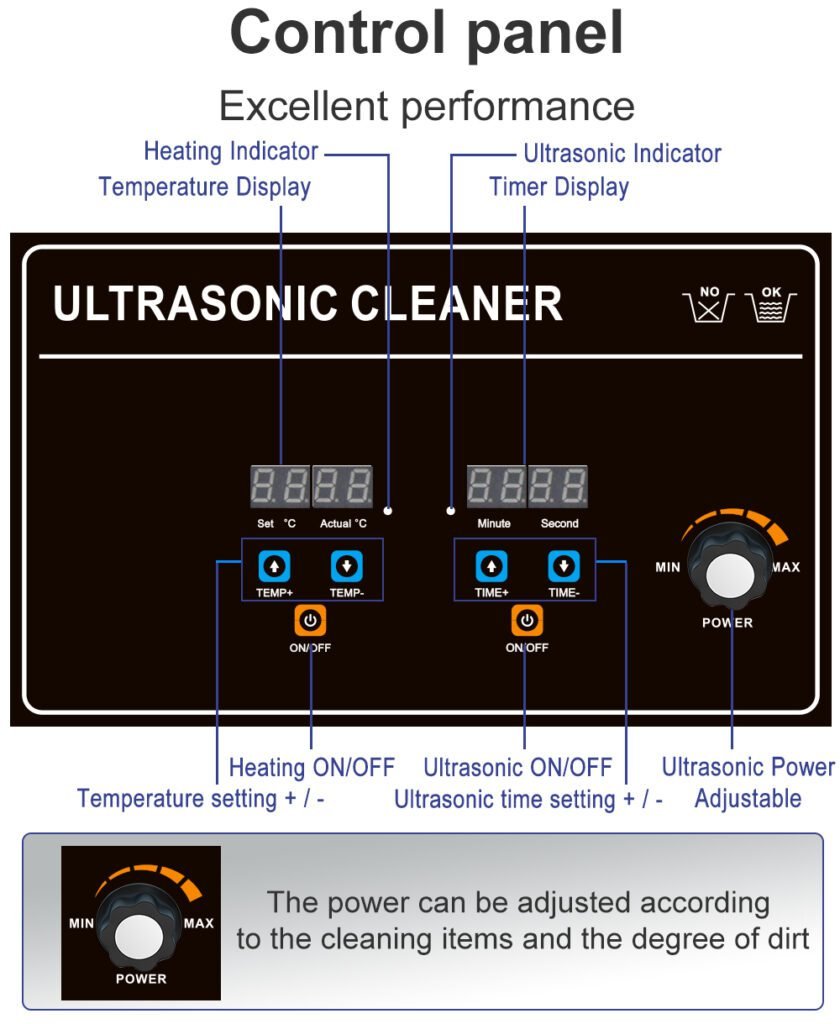

Intelligent Digital Control System

Touch Operation: Capacitive touch buttons, responsive

Dual Temp Display: Real-time display of set temp and actual water temp

Time Control: 0-30 minute timer with countdown display

Status Indicators: Independent LEDs for Heating, Ultrasound, Power status

Professional Industrial Structure

SUS304 Inner Tank: 1.2mm thick stainless steel, corrosion-resistant, easy to clean

Reinforced Structure: Rib design ensures no deformation during long-term use

Safety Design: Double safety switch, dry-burn protection

Cooling System: Optimized air duct design ensures stable long-term operation

Detailed Technical Specifications of Washer 96L Soak Tank

ST Series Full Model Technical Parameters

Power Adjustment Application Guide of Stainless Steel Gun Parts Bullets Hardware Tube Cleaner With Digital Heater

Recommended Power Settings by Cleaning Object

Cleaning Object Type

Recommended Power

Temperature Setting

Time Setting

Suitable Models

Jewelry, Jade, Luxury Watches

MIN (20-30%)

30-40°C

3-5 min

020ST-030ST

Eyeglasses, Contact Lens Cases

Low Power (30-40%)

35-45°C

3-8 min

020ST-031ST

Electronic PCBs, Chips

Medium-Low (40-60%)

40-50°C

5-10 min

020ST-040ST

Laboratory Glassware

Medium (50-70%)

45-60°C

10-15 min

030ST-060ST

Dental, Surgical Instruments

Medium-High (60-80%)

60-70°C

10-20 min

031ST-080ST

Hardware Tools, Parts

High (70-90%)

60-75°C

15-25 min

040ST-100ST

Molds, Engine Parts

MAX (90-100%)

70-80°C

20-30 min

060ST-100ST

Adjustment Strategy by Contamination Level

Light Contamination (Dust, Fingerprints):

Power: 30-50%

Temperature: Room temp – 40°C

Time: 3-8 minutes

Medium Contamination (Grease, Polishing Paste):

Power: 50-75%

Temperature: 45-65°C

Time: 10-20 minutes

Heavy Contamination (Carbon Deposits, Cured Grease):

Power: 75-100%

Temperature: 65-80°C

Time: 20-30 minutes

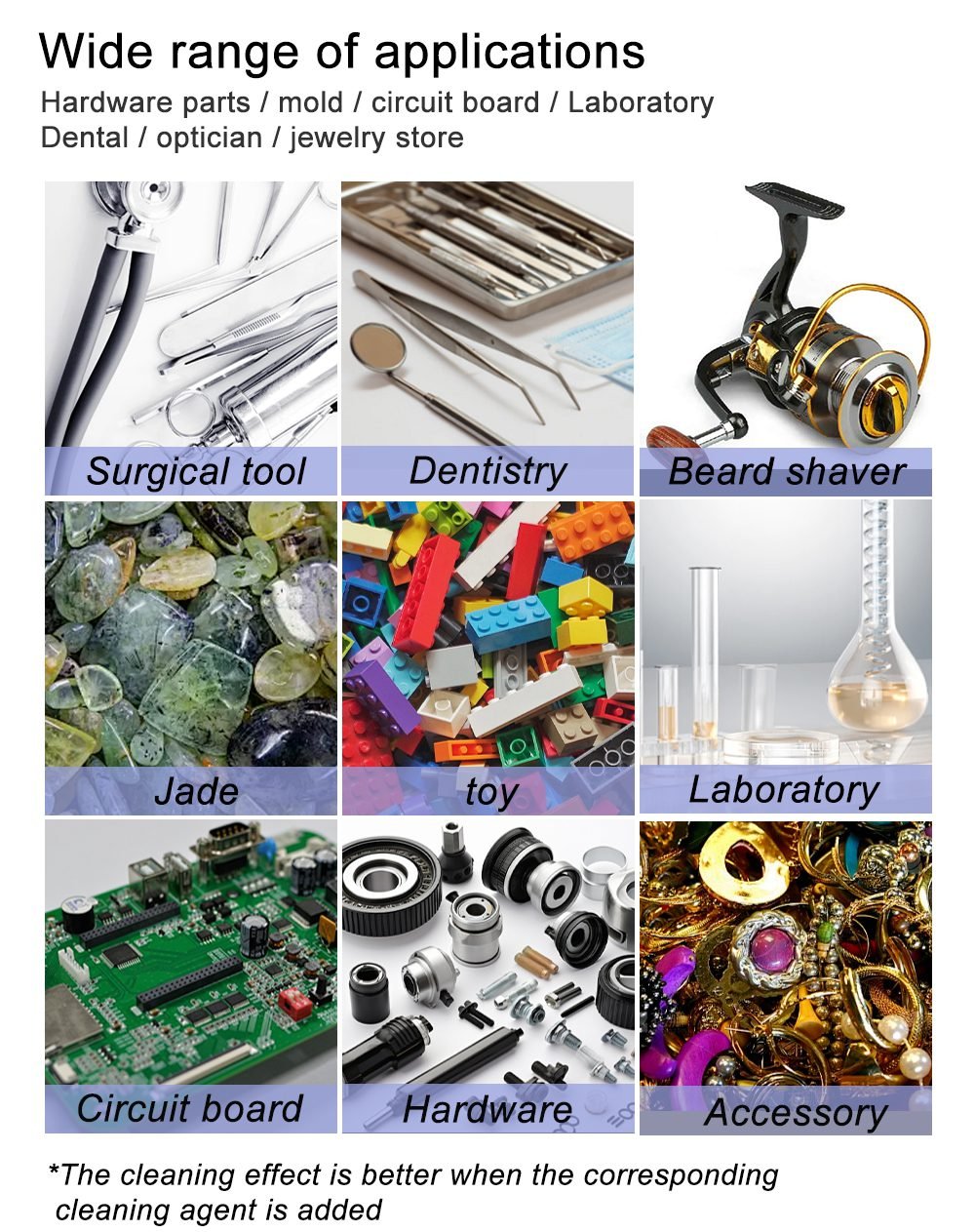

Professional Application Solutions of Large Capacity Engine Part DPF Machinery Components Metal Part Industrial Cleaner

Precision Electronics Manufacturing

Challenge: Fragile components require thorough cleaning without damage

ST Intelligent Solution:

Low power for gentle cleaning of BGA, QFP packages

Medium power effectively removes flux residue

Different power settings possible for different component areas

Recommended Models: 3.2L-10L ST Series

Quality Benefit: Yield increases 2-5%, rework rate decreases

Jewelry & Watch Repair

Industry Traits: High-value items, diverse materials, varying cleaning needs

ST Flexible Response:

Gold, Platinum: Medium power ensures cleanliness

Pearls, Gemstones: Low power protects surface luster

Mechanical Watch Movements: Targeted power removes old grease

Optimal Choice: 3.2L-6.5L ST Series

Customer Value: 100% cleaning safety, increased customer satisfaction

Mold Maintenance & Manufacturing

Cleaning Needs: Balance surface protection with deep hole cleaning

ST Powerful Solution:

Full power for stubborn release agents

Adjustable power adapts to different mold materials

Heating function accelerates chemical reactions

Suitable Models: 15L-30L ST Series

Efficiency Gain: Cleaning time reduced by 40%, mold lifespan extended

Diversified Repair Workshops

Business Traits: Wide variety of items, different sizes

ST Versatile Machine:

Morning: Low power for glasses, jewelry

Afternoon: High power for automotive parts

Switch anytime, no need to change equipment

Recommended Configuration: 6.5L-15L ST Series

ROI: One machine replaces multiple specialized units, saving costs

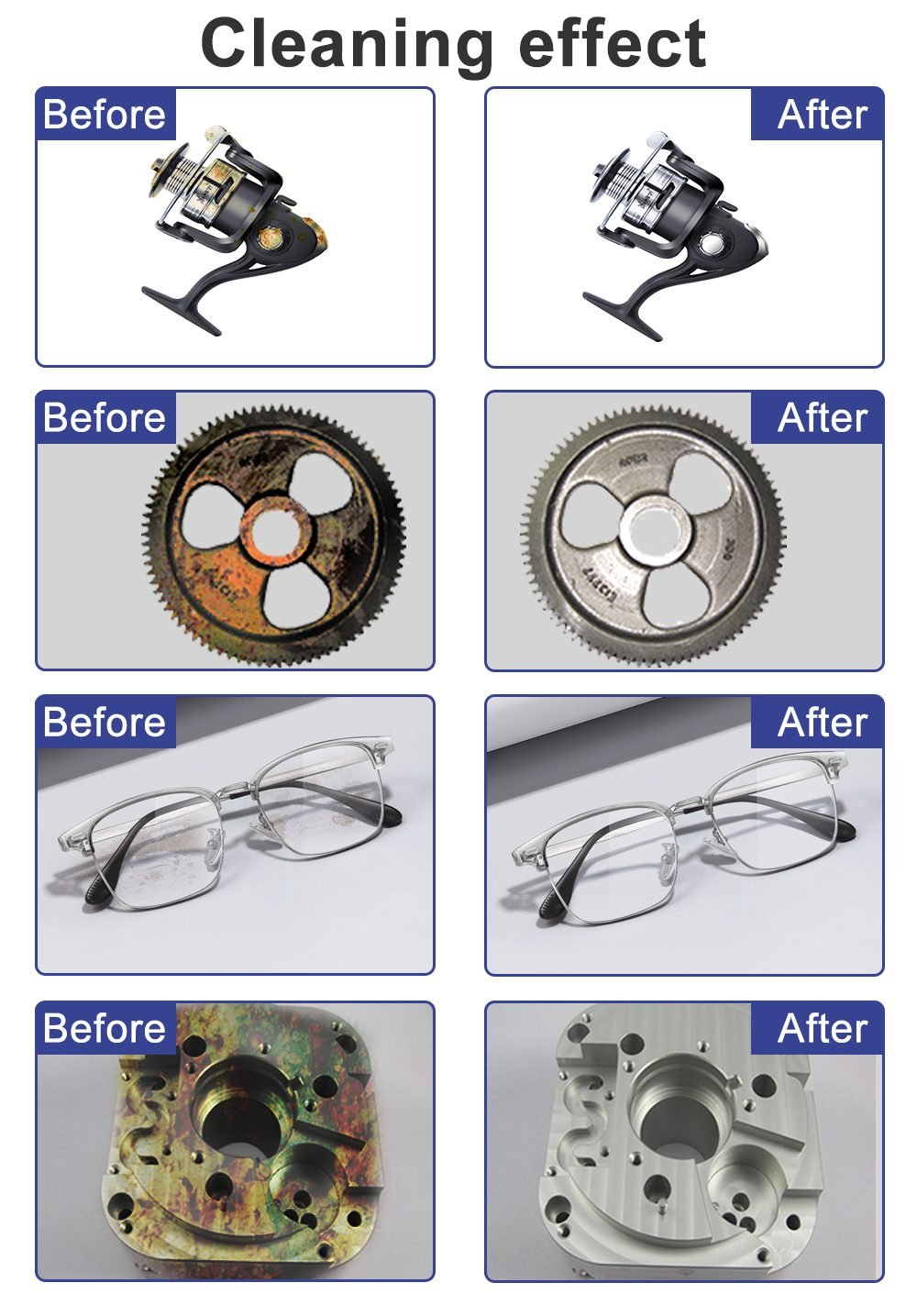

Cleaning Effect Comparison of Industry Cleaner Washing Tank Engine Block Parts DPF Bath Sonic Equipment

Real Cleaning Cases

Engine Carburetor Cleaning

Before: Heavy grease, clogged channels

Power Setting: 100% Full Power

Temp/Time: 75°C, 25 minutes

After: Grease completely removed, channels clear

Precision Watch Movement

Before: Old lubricant solidified, poor operation

Power Setting: 40% Low Power

Temp/Time: 40°C, 8 minutes

After: Grease removed, parts undamaged

Electronic Soldering Fixture

Before: Flux buildup affecting accuracy

Power Setting: 60% Medium Power

Temp/Time: 50°C, 12 minutes

After: Flux completely cleared, fixture like new

Intelligent Operation Guide of Indusdrial Cleaner Industry DPF Parts Engine Blocks

Three-Step Intelligent Cleaning

Analysis & Setup Phase

Identify workpiece material and contamination type

Set initial power referencing the power recommendation table

Set appropriate temperature and cleaning time

Optimization & Adjustment Phase

Observe initial cleaning effect

Fine-tune power as needed

Pause anytime to adjust parameters

Standardization Phase

Record successful cleaning parameters

Establish standardized cleaning process cards

Achieve batch cleaning consistency

Power Adjustment Techniques

Progressive Increase: Start low, gradually increase to ideal effect

Zonal Cleaning: Complex items can be cleaned with different power per zone

Pre-treatment: Heavily soiled items pre-treated with high power first

Protective Cleaning: Delicate items cleaned at low power first, assess before increasing

Maintenance Essentials of Ultrasonic Carburetor Cleaner

Daily Maintenance

Power Component Check: Regularly check power knob sensitivity

Transducer Status: Observe if all transducers work evenly

Control Panel: Keep touch panel clean and dry

Cooling System: Regularly clean vents for good heat dissipation

Professional Maintenance Schedule

Monthly: Power output calibration check

Quarterly: Transducer efficiency test

Semi-annual: Comprehensive control system inspection

Annual: Full maintenance by manufacturer’s professionals

Customer Value Analysis of Ultrasonic Gun Cleaning System

Value for End Users

✓ Wide Cleaning Adaptability: One machine meets all needs from delicate to heavy soil

✓ Flexible Process Optimization: Real-time adjustment based on actual results

✓ Equipment Investment Savings: No need to buy multiple machines of different powers

✓ Improved Cleaning Quality: Precise power control delivers better cleaning

✓ Reduced Operating Cost: Rational power use saves electricity

Value for Distributors

✓ Product Uniqueness: Stepless power adjustment creates clear technical advantage

✓ Strong Solution Capability: Can provide personalized cleaning solutions

✓ High Customer Stickiness: Intelligent features require professional support

✓ Premium Pricing Potential: High-tech products support higher pricing

✓ Market Education Opportunity: Need to educate market on power adjustment value

Technical Certification & Quality Assurance of Tabletop Ultrasonic Cleaning Station

Performance Certification

Power Accuracy Certification: Power adjustment linearity error <3%

Transducer Efficiency Certification: Energy conversion efficiency >85%

Temperature Control Certification: Control accuracy ±1°C

Safety Performance Certification: Passed full series safety tests

Quality Assurance System

Component-level Testing: Each transducer tested individually

Complete Machine Aging Test: 48-hour continuous full-load test

Power Curve Test: Linearity test across full power range

Environmental Adaptability Test: High/low temp, humidity environment tests

Why Choose the ST Series?

Technological Innovation

Industry Breakthrough: First to achieve full-series stepless power adjustment

Patent Technology: Intelligent power control system patent

Performance Leadership: 800Pa impact force leads the industry

Usage Economy

Versatile Machine: Reduces number of equipment purchases

Energy Optimization: Adjust power on-demand, saves electricity

Easy Maintenance: Standardized design lowers maintenance cost

Application Foresight

Adapts to Future Needs: Adjustable power adapts to new materials/processes

Technical Extensibility: Reserves interface for smart upgrades

Industry Adaptability: Covers existing and emerging industry needs

- Reply within 24 hrs

Get A Quote

Partner with Cleaningsonic to access high-quality ultrasonic cleaning machines that meet the needs of industries like automotive, electronics, and medical equipment. Our OEM/ODM capabilities, flexible small-order support, and global export experience help you expand your market with confidence. Contact us today to explore how we can elevate your distribution business!

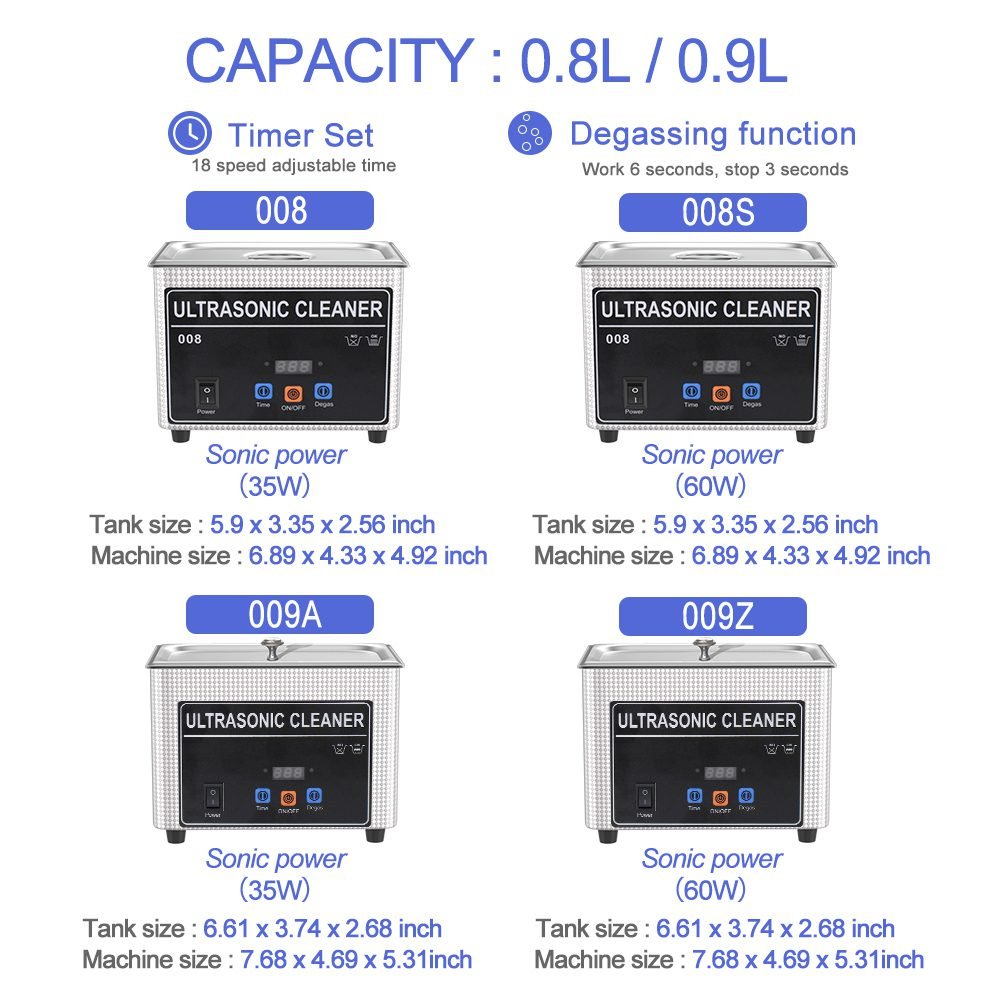

Main Product

Compact Ultrasonic Cleaners for Jewelry

008 Series (0.8L/0.9L)

Heated Ultrasonic Cleaner

009 Series (1.3L)

Ultrasonic Cleaner for Tool Cleaning

010 Series (2L)

Laboratory Medical Cleaning Equipment

020 Series (3.2L)

Professional Grade Cleaning Solutions

030 Series (4.5L)

Industrial Grade Deep Cleaning Equipment

031 Series (6.5L)

Industrial Batch Cleaning System

060 Series(15L)

Industrial Ultrasonic Cleaner

080 Series (22L)

Industrial Ultrasonic Cleaning Machine

100 Series (30L)

Blue Light Ultrasonic Cleaner

CS010 Series(480ML)

Ultrasonic Cleaner for Eyeglass Jewelry

CS020 Series (680ML)

2-in-1 Ultrasonic UV Cleaner

200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Neoclassical Sofa

Model 200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Neoclassical Sofa

Model 200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Hot Tags & Keywords

Core Function Keywords:

Adjustable Power Ultrasonic Cleaner Stepless Adjustment Cleaner ST Series Ultrasonic Cleaner Intelligent Power Control Adjustable Impact Force Cleaning

Technical Parameter Keywords:

800Pa Impact Force 60W Transducer 40KHz Industrial Frequency 0-100% Power Adjustment Digital Touch Panel

Application Scenario Keywords:

Precision Electronics Cleaner Jewelry Watch Cleaning Equipment Mold Maintenance Cleaner Multifunctional Repair Cleaning Laboratory Intelligent Cleaning

Capacity Specification Keywords:

Small Adjustable Power Cleaner Medium Industrial Cleaning Equipment Large Capacity Adjustable Power Cleaning Benchtop Intelligent Cleaner Multiple Capacity Options

Value Proposition Keywords:

One Machine Multiple Use Solution Intelligent Cleaning Equipment Energy Efficient Cleaner Process Optimization Tool Technologically Leading Product

.png)

.png)

.png)