PRODUCT

Contact withus for any advice

Need help? Talk to an expert

+86 19068026712

SD Series Multifunctional Ultrasonic Cleaner | Degas & Dual Semiwave | 1.3L-30L Full Range - Cleaningsonic

Cleaningsonic SD Series ultrasonic cleaner, standard with degas function & dual semiwave mode, 40KHz industrial transducers, digital touch control, 1.3L-30L multiple capacities. Ideal for hardware molds, circuit boards, laboratories, jewelry, and eyewear cleaning.

SD Series Multifunctional Ultrasonic Cleaner

- Normal wave/Double Semiwave+Degas+Heating+Timer

- Capacity: 1.3L-30L

- Sonice Power: 60W-900W

- Frequency: 40KHz

- Temp Range:20-80°C

- Timer Range: 0-30 min

SD Series Multifunctional Ultrasonic Cleaner - Degas & Dual Semiwave Technology | 1.3L-30L Full Range | Digital Touch Smart Cleaning

Product Overview of Ultrasonic Cleaning for Surface Preparation

SD Series Multifunctional Ultrasonic Cleaner – Professional Cleaning Solution Featuring Advanced Degas & Dual Semiwave Technology

The Cleaningsonic SD Series ultrasonic cleaner is an innovative product designed for high-standard cleaning requirements. The entire series comes standard with degas function and dual semiwave mode, combined with 40KHz industrial-grade transducers, digital touch operation, and intelligent temperature control systems, delivering exceptional cleaning performance for precision parts, complex structures, and sensitive materials. This series covers 8 capacity specifications from 1.3L to 30L, meeting comprehensive cleaning needs from personal studios to medium-sized workshops.

As a professional ultrasonic cleaner manufacturer, we deeply understand the core cleaning quality demands across various industries. The SD Series is specifically optimized for challenging scenarios such as blind hole part cleaning, precision surface treatment, and bubble-sensitive applications, making it the ideal choice for electronics manufacturing, mold maintenance, medical equipment, jewelry, watches, and more.

Product Series Overview of Ultrasonic Cleaning for Hydraulic

Components

SD Series Core Features

Full Series Standard: Degas function + Dual semiwave mode

Unified Technology: 40KHz industrial transducers + Digital touch control system

Intelligent Control: Independent temperature/time adjustment + Operation status display

Professional Design: 304 stainless steel tank + Multiple safety protections

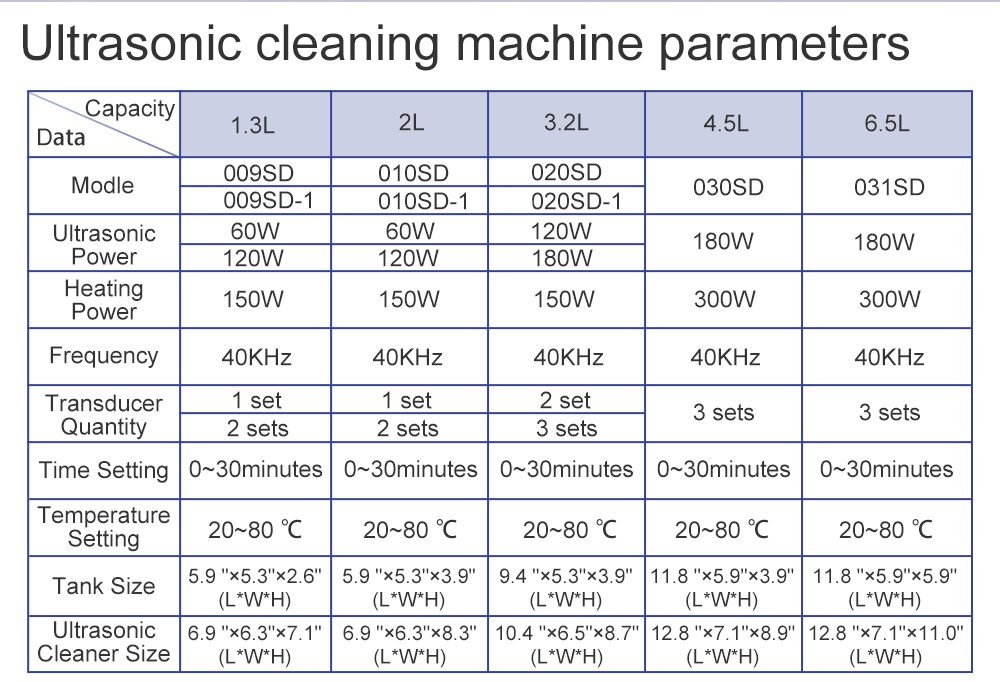

Capacity & Power Matrix

Capacity

Model Series

Ultrasonic Power

Heating Power

Transducers

Applications

1.3L

009SD/009SD-1

60W/120W

150W

1/2 sets

Jewelry, Eyewear, Watches

2L

010SD/010SD-1

60W/120W

150W

1/2 sets

Dental Clinics, Small Studios

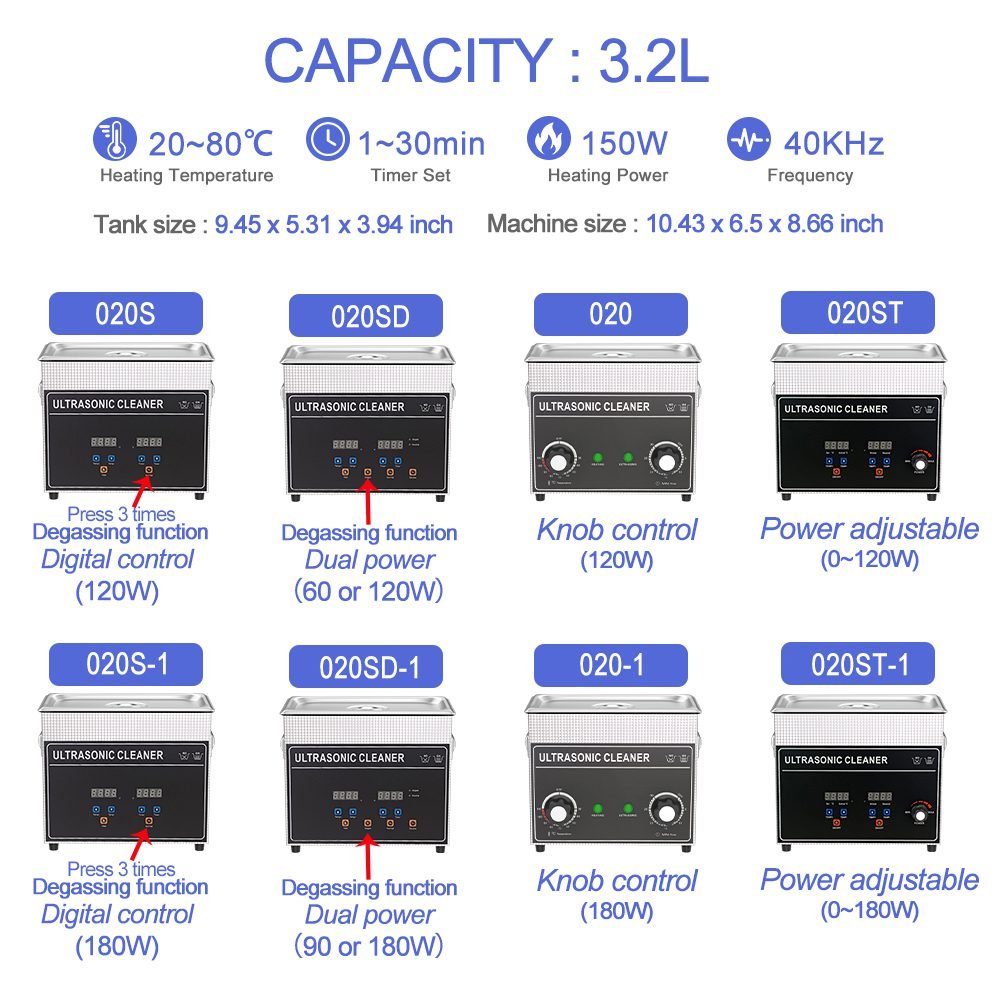

3.2L

020SD/020SD-1

120W/180W

150W

2/3 sets

Electronics Repair, Laboratories

4.5L

030SD

180W

300W

3 sets

Small Molds, Hardware Tools

6.5L

031SD

180W

300W

3 sets

Automotive Small Parts, Optical Devices

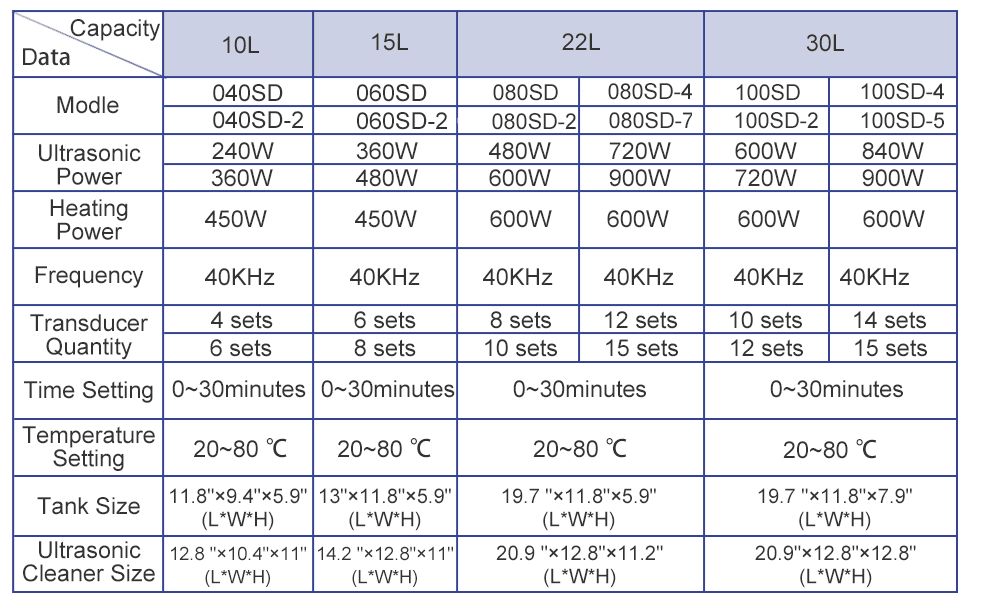

10L

040SD Series

240W-360W

450W

4-6 sets

Small/Medium Batch Production

15L

060SD Series

360W-480W

450W

6-8 sets

Mold Cleaning, Industrial Maintenance

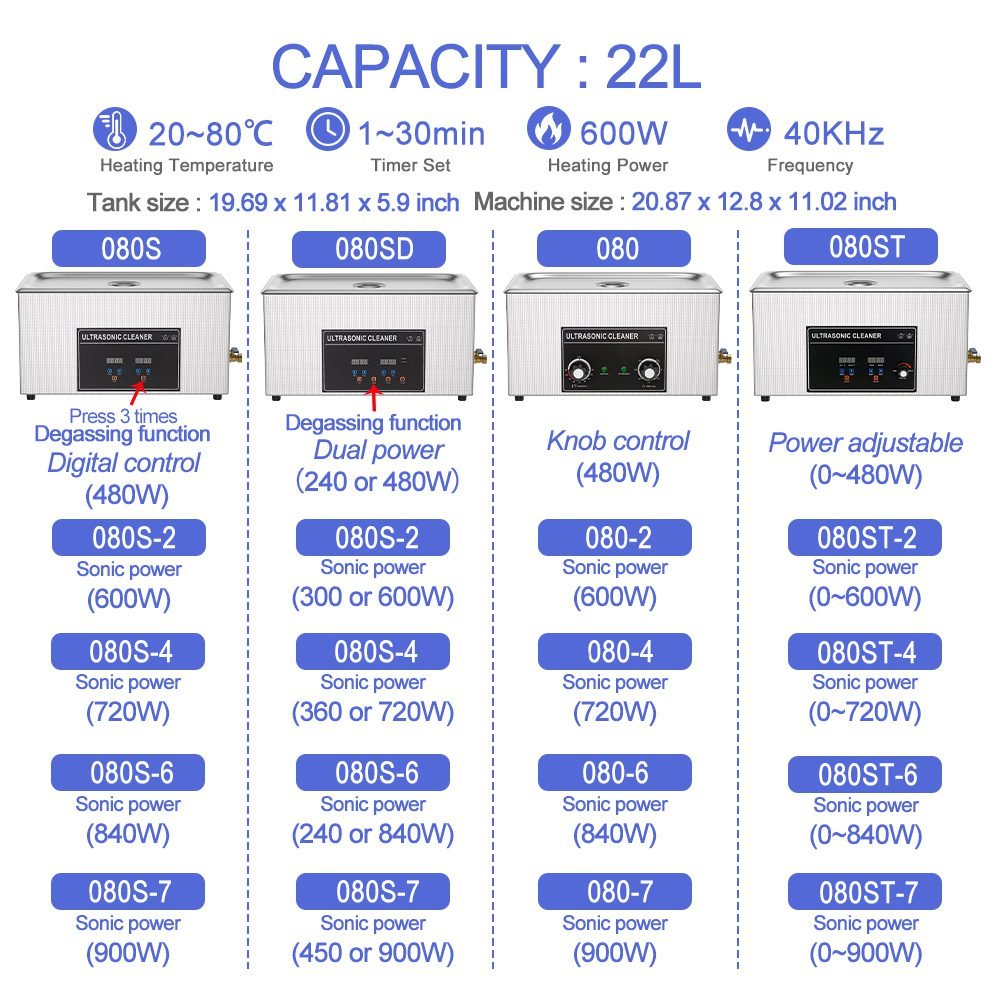

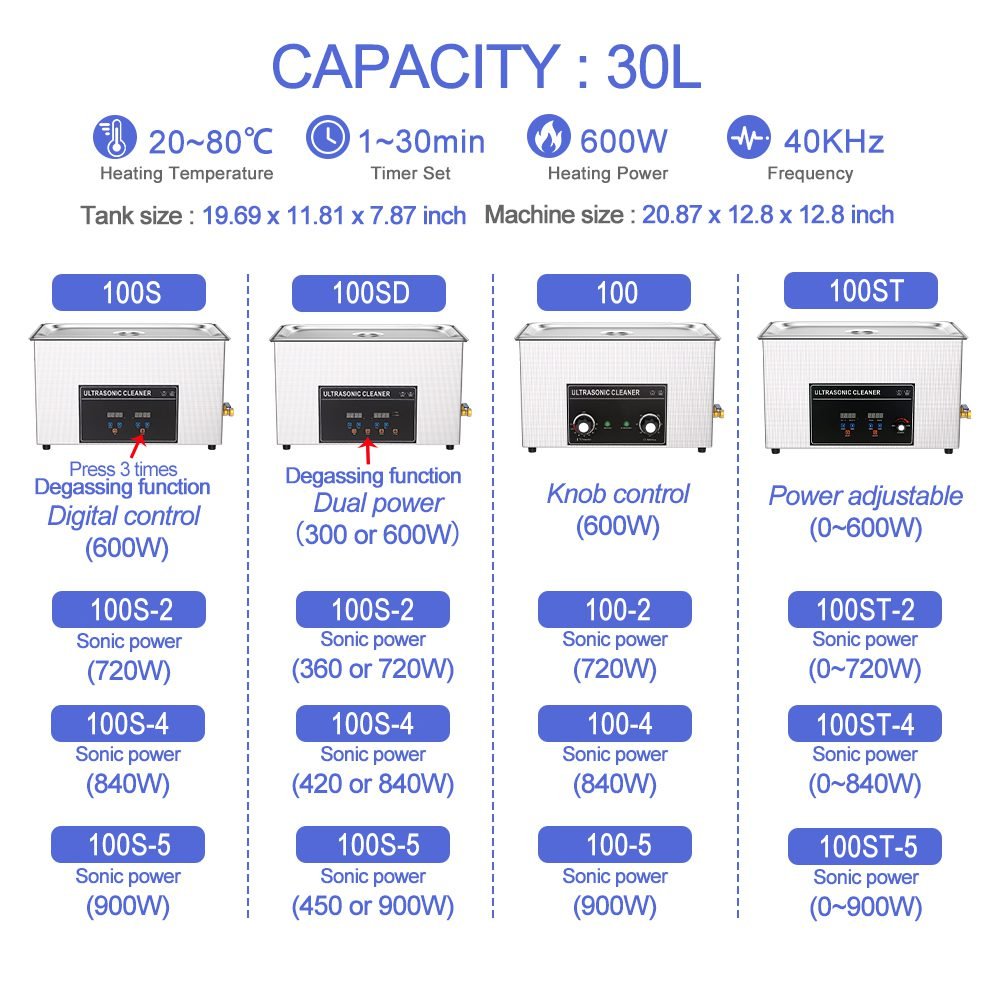

22L-30L

080SD/100SD Series

480W-900W

600W

8-15 sets

Industrial Batch Cleaning

Core Technical Highlights of Ultrasonic Cleaning for Automotive Fuel Injectors

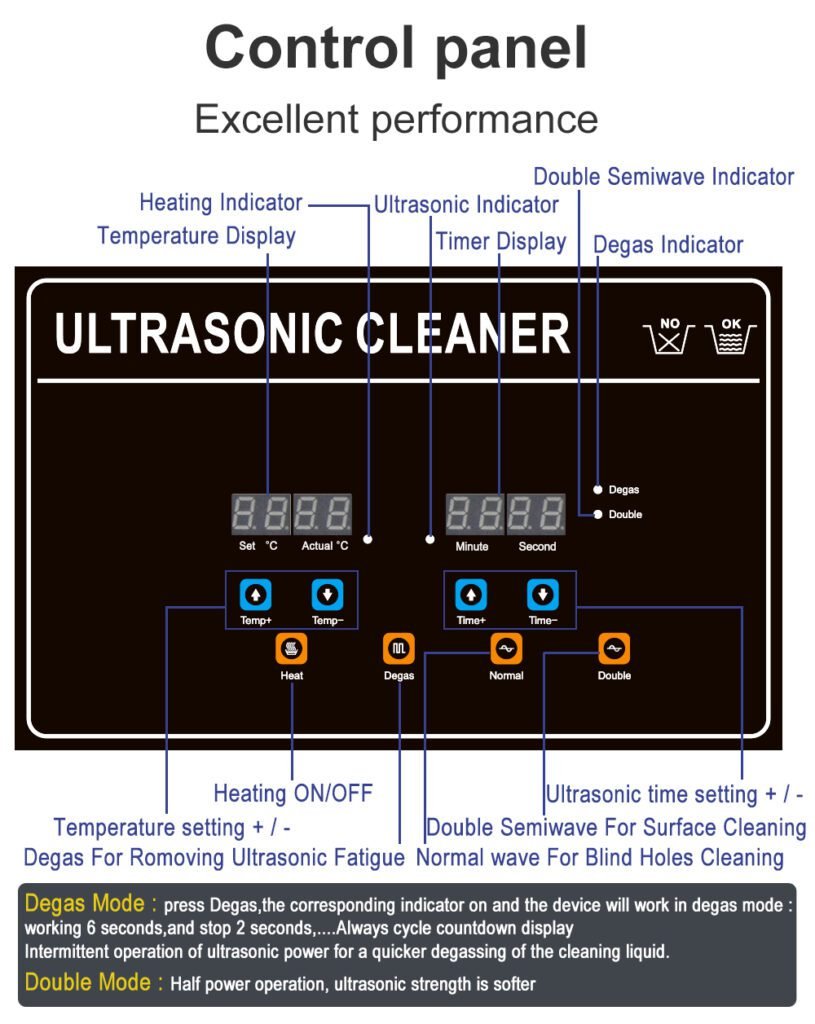

Degas Function

Technical Principle: Intermittent ultrasonic operation mode (6 seconds on, 2 seconds off cycle)

Core Value: Rapidly removes dissolved air bubbles from the cleaning solution

Application Scenarios:

Blind hole, deep hole part cleaning

Precision optical component cleaning

Processes requiring avoidance of bubble interference

Operation Method: One-touch start, dedicated indicator shows status

Dual Semiwave Mode

Technical Feature: Half-power operation, gentler ultrasonic intensity

Protection Function: Prevents surface damage to precision parts

Suitable Materials:

Brittle materials like jewelry, jade

Polished surfaces, mirror-finished workpieces

Thin-walled structures, precision electronic components

Mode Switching: Independent button, free switching with normal mode

Intelligent Touch Control System

Digital Touch Panel: Responsive and intuitive operation

Dual Temperature Display: Shows both set temperature and actual temperature

Countdown Display: Precise cleaning time control down to the second

Status Indicators: Independent indicators for Heating, Ultrasound, Degas, Dual Semiwave

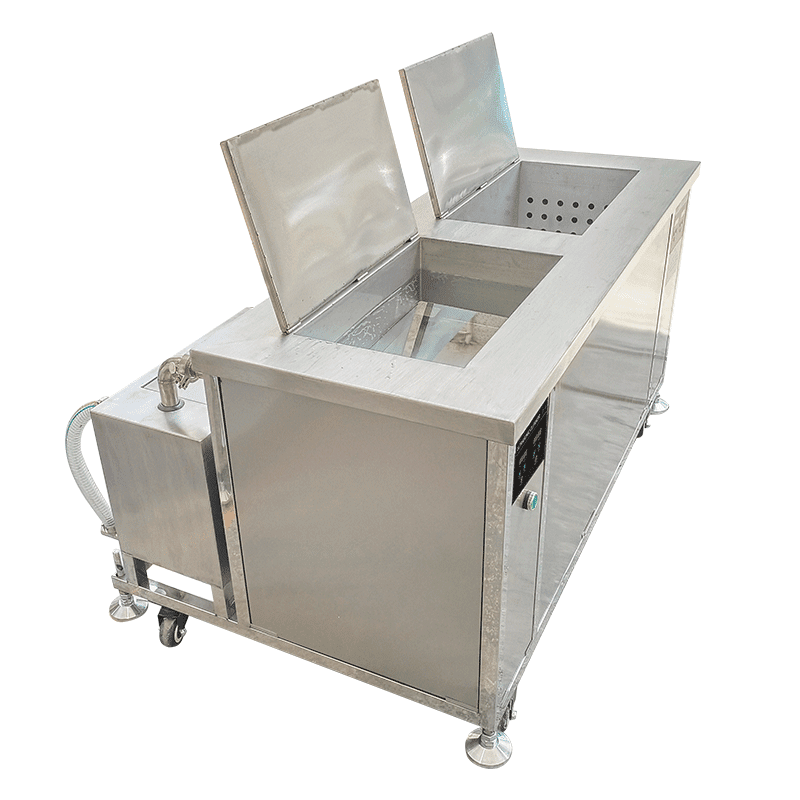

Professional Industrial Design

SUS304 Inner Tank: Food-grade stainless steel, corrosion-resistant and easy to clean

Multi-point Heat Dissipation System: Ensures stable long-term operation

Double Safety Switch: Prevents misuse, ensures operational safety

Brass Core Drain Valve: Durable, reliable, smooth drainage

Detailed Technical Specifications of Ultrasonic Cleaning for Electronic Contacts

Small Series Technical Specifications (1.3L-6.5L)

Standard Functional Configuration

Control Method: Digital touch panel

Display System: Dual temperature display + Timer countdown

Operating Modes: Normal wave + Dual semiwave + Degas mode

Safety Features: Double safety switch, Overheat protection

Drainage System: Brass core drain valve

Heat Dissipation Design: Multi-position heat dissipation system

Professional Application Solutions of Ultrasonic Cleaning for Semiconductor Components

Mold Manufacturing & Maintenance

Cleaning Challenge: Oil accumulation in blind holes, cleaning complex structures

SD Solution Advantages:

Degas function solves deep hole cleaning challenges

Dual semiwave protects mold surface finish

Powerful power thoroughly removes release agents

Recommended Models: 15L-30L SD Series

Efficiency Improvement: Mold life extended by 30%, cleaning time reduced by 50%

Electronic Circuit Board Cleaning

Cleaning Requirements: Thorough flux removal without damaging components

SD Technology Application:

Dual semiwave mode protects delicate solder joints

Precise temperature control ensures optimal cleaning agent activity

Uniform ultrasonic field for dead-angle-free cleaning

Suitable Models: 3.2L-10L SD Series

Quality Assurance: Cleaning pass rate increased to 99.5%

Medical Equipment Cleaning

Industry Standards: Pre-disinfection cleaning, no biofilm residue

SD Professional Functions:

Degas function ensures complete liquid contact

Dual semiwave protects instrument blade sharpness

304 stainless steel tank meets hygiene standards

Recommended Capacity: 2L-6.5L SD Series

Compliance Assurance: Meets medical device cleaning specifications

Jewelry & Watch Precision Cleaning

Special Needs: Thorough cleaning without surface damage

SD Gentle Solution:

Dual semiwave mode enables gentle deep cleaning

Small capacity design suitable for delicate workpieces

Digital control ensures cleaning consistency

Optimal Choice: 1.3L-3.2L SD Series

Value Proposition: Enhanced product luster, increased customer satisfaction

Optical Devices & Lenses

Cleaning Difficulty: Risk of surface scratches, water stain residue

SD Precision Cleaning:

Dual semiwave prevents lens surface damage

Degas function prevents bubble adhesion

Precise temperature control reduces water stains

Suitable Models: 2L-4.5L SD Series

Cleaning Result: Light transmittance maintained above 99%

Cleaning Effect Comparison of Ultrasonic Cleaning for High-Precision Parts

Actual Cleaning Case Studies

Hardware Parts Cleaning

Before Cleaning: Heavy grease, metal debris present

After Cleaning: Clean surface, no grease residue

Mode Used: Normal wave + Degas function

Cleaning Time: 15 minutes

Circuit Board Cleaning

Before Cleaning: Visible flux residue

After Cleaning: Bright solder joints, no chemical residue

Mode Used: Dual semiwave mode

Cleaning Temperature: 45°C

Jewelry Cleaning

Before Cleaning: Dull surface, stains present

After Cleaning: Luster restored, details clear

Mode Used: Dual semiwave + Degas

Cleaning Agent: Dedicated jewelry cleaning solution

Intelligent Operation Guide of Ultrasonic Cleaning with Ultrahigh Frequency

One-Touch Cleaning Process

Preparation Stage

Add appropriate amount of water and cleaning agent

Place cleaning objects in the basket

Parameter Setting

Touch to set cleaning temperature (20-80°C)

Set cleaning time (0-30 minutes)

Select operating mode (Normal/Dual Semiwave)

Function Activation

Activate heating function for preheating

Activate degas function as needed

Start ultrasonic cleaning

Completion

Automatic stop when timer ends

Remove cleaned objects

Drain and clean the equipment

Special Function Operation

Degas Function: Run for 3-5 minutes before cleaning to remove liquid bubbles

Dual Semiwave Switching: Can switch anytime during cleaning to adapt to different workpieces

Temperature Fine-tuning: Adjust in 1°C increments to optimize cleaning effect

Time Reset: Adjust remaining time during operation

Maintenance Specifications of Ultrasonic Cleaning for Large Parts

Daily Maintenance

After Each Use: Drain cleaning solution, rinse with clean water

Weekly Cleaning: Clean drain valve, check seals

Monthly Check: Check transducer operating status

Quarterly Maintenance: Thorough cleaning, check electrical connections

Professional Maintenance Recommendations

Use Appropriate Cleaning Agents: Avoid strong acids/alkalis causing corrosion

Control Liquid Temperature: Do not exceed the 80°C upper limit

Avoid No-load Operation: Do not activate ultrasound without liquid

Regular Professional Inspection: Recommended annual professional maintenance

Customer Value Analysis of Ultrasonic Cleaning for Contaminated Parts

Value for End Userstext

✓ Enhanced Cleaning Quality: Degas function solves blind hole cleaning challenges

✓ Expanded Application Range: Dual semiwave mode protects sensitive materials

✓ Operation Intelligence: Digital touch simplifies operation

✓ Optimized Cleaning Efficiency: Multi-function combination improves cleaning results

✓ Equipment ROI: Multi-purpose machine reduces equipment procurement costs

Value for Distributorstext

✓ Product Differentiation: Unique features create market competitive advantage

✓ Broad Application Fields: Covers more high-value industries

✓ Strong Technical Support: Professional functions require professional guidance

✓ High Customer Stickiness: Solves customer pain points, builds long-term cooperation

✓ Better Profit Margin: High value-added products bring better returns

Quality Control System of Ultrasonic Frequency Cleaning

Manufacturing Standards

Material Standards: SUS304 stainless steel, compliant thickness

Production Process: Automated welding, precision control

Assembly Requirements: Professional tooling ensures assembly consistency

Testing Procedure: Full functional test for each unit

Performance Verification

Ultrasonic Intensity Test: Multi-point inspection ensures uniformity

Temperature Accuracy Verification: Multi-point temperature measurement, ±1°C accuracy

Functional Integrity: Independent testing of all modes

Safety Performance: Comprehensive electrical safety testing

Certifications & Compliance

Product Certifications: CE, RoHS certified

Safety Standards: Compliant with IEC international electrical standards

Material Safety: 304 stainless steel food-grade certification

Environmental Requirements: Compliant with environmental production standards

Technical Support & Service of Ultrasonic Washing Machine

Pre-sales Service

Application Consultation: Provides industry cleaning solution recommendations

Model Recommendation: Recommends the best model based on needs

Sample Testing: Provides sample cleaning test service

After-sales Service

Installation Guidance: Provides detailed installation and operation guides

Operation Training: Video tutorials and on-site training

Technical Consultation: Professional engineer technical support

Repair Service: Quick response to repair needs

Accessories & Consumables

Standard Accessories: Stainless steel basket, drainage pipe, etc.

Specialized Consumables: Recommended matching cleaning agents

Spare Parts Supply: Long-term inventory of common spare parts

Upgrade Services: Function upgrades and modification services

Why Choose the SD Series?

Technological Leadership

Industry First: Degas & dual semiwave functions standard even in small machines

Proprietary Technology: Unique degas operation mode design

Intelligent Control: Digital touch and intelligent display system

Application Professionalism

Problem-Oriented: Developed to address actual cleaning challenges

Industry Adaptation: Meets special needs of multiple industries

Effect Validation: Validated through extensive real-world applications

Usage Convenience

Simplified Operation: One-touch intelligent operation

Easy Maintenance: Modular design facilitates maintenance

Strong Adaptability: Flexible switching between multiple work modes

Investment Value

Comprehensive Functions: One machine meets multiple needs

Long-term Reliability: Industrial-grade design ensures durability

Upgrade Potential: Supports future functional expansion

- Reply within 24 hrs

Get A Quote

Partner with Cleaningsonic to access high-quality ultrasonic cleaning machines that meet the needs of industries like automotive, electronics, and medical equipment. Our OEM/ODM capabilities, flexible small-order support, and global export experience help you expand your market with confidence. Contact us today to explore how we can elevate your distribution business!

Main Product

Compact Ultrasonic Cleaners for Jewelry

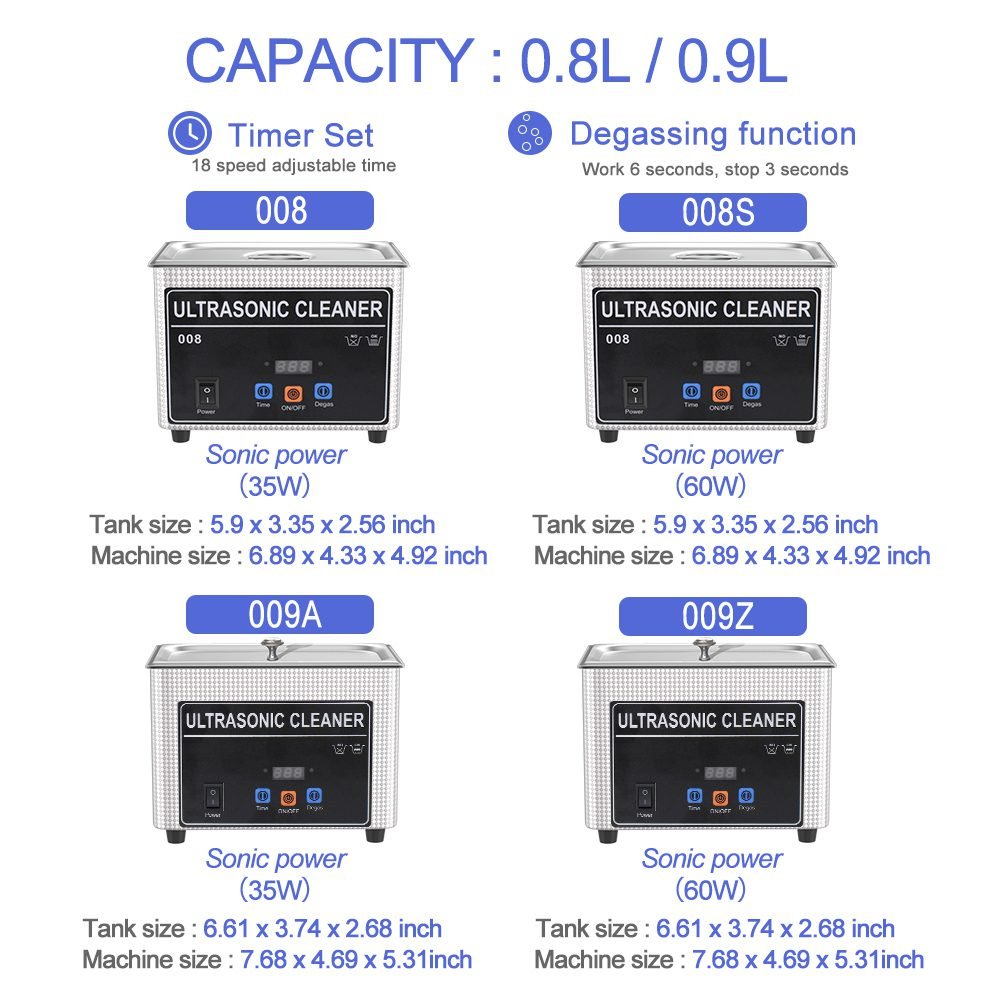

008 Series (0.8L/0.9L)

Heated Ultrasonic Cleaner

009 Series (1.3L)

Ultrasonic Cleaner for Tool Cleaning

010 Series (2L)

Laboratory Medical Cleaning Equipment

020 Series (3.2L)

Professional Grade Cleaning Solutions

030 Series (4.5L)

Industrial Grade Deep Cleaning Equipment

031 Series (6.5L)

Industrial Batch Cleaning System

060 Series(15L)

Industrial Ultrasonic Cleaner

080 Series (22L)

Industrial Ultrasonic Cleaning Machine

100 Series (30L)

Blue Light Ultrasonic Cleaner

CS010 Series(480ML)

Ultrasonic Cleaner for Eyeglass Jewelry

CS020 Series (680ML)

2-in-1 Ultrasonic UV Cleaner

200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Neoclassical Sofa

Model 200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Neoclassical Sofa

Model 200 \201 (230ML)

Neoclassical Sofa

060 Series(15L)

Neoclassical Sofa

080 Series (22L)

Hot Tags & Keywords

Core Function Keywords:

Degas Ultrasonic Cleaner Dual Semiwave Cleaning Equipment SD Series Ultrasonic Cleaner Touch Ultrasonic Cleaner Multifunctional Cleaner

Technical Feature Keywords:

40KHz Industrial Transducer Digital Touch Panel SUS304 Stainless Steel Tank Intelligent Temperature Control System Intermittent Degas Technology

Application Industry Keywords:

Mold Ultrasonic Cleaner Circuit Board Cleaning Equipment Medical Equipment Cleaner Jewelry Precision Cleaning Optical Device Cleaning

Capacity Specification Keywords:

Small Ultrasonic Cleaner Benchtop Cleaning Equipment Laboratory Cleaner Industrial Batch Cleaner Multiple Capacity Options

Business Value Keywords:

Professional Cleaning Solution OEM Ultrasonic Equipment High Value-Added Cleaner Global Distribution Cooperation Technologically Leading Product

.png)

.png)

.png)