100 Series 30L Industrial Ultrasonic Cleaning Machine - 40KHz Frequency | Heating & Degas Functions | Smart Digital Control

Cleaningsonic 100 Series 30L ultrasonic cleaner with 40KHz transducer, 304 stainless steel tank, heating & degas functions. 600W-900W options, dual power mode. Ideal for lab, mold, electronics cleaning. OEM supported, German plug available.

100 Series 30L Ultrasonic Cleaner - Ideal Solution for Medium-Scale Industrial Cleaning

Product Overview of Digital For Car Parts Engine Parts Cleaning Machine

The Cleaningsonic 100 Series 30L ultrasonic cleaner is specifically designed for medium to high-capacity cleaning requirements, making it the perfect choice for laboratories, mold factories, automotive repair centers, and electronics manufacturing facilities. This product features 40KHz industrial transducers, intelligent temperature control systems, and innovative dual-power technology, offering power options from 600W to 900W to meet various industrial cleaning applications.

As a professional industrial ultrasonic cleaner manufacturer, we provide global distributors with a moderate-capacity, fully-featured, and performance-stable 30L cleaning solution. The 100 Series has successfully entered markets including Germany, the USA, and Southeast Asia, becoming the preferred equipment for numerous industrial users.

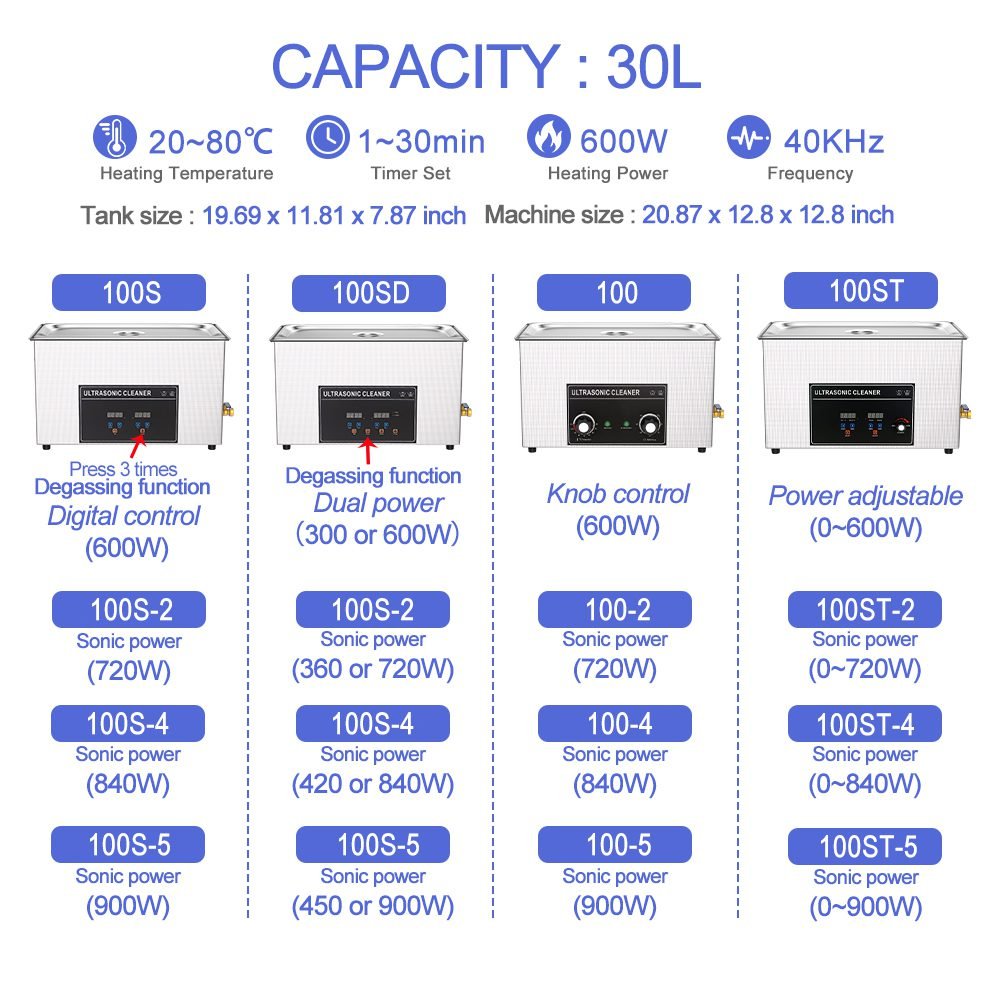

Technical Specifications of Industrial Ultrasonic Cleaning System

Basic Technical Parameters

Item

Specifications

Product Models

100 / 100S / 100SD / 100ST

Tank Capacity

30 Liters (Large capacity design)

Tank Dimensions

500×300×200mm (19.69×11.81×7.87 inches)

Machine Dimensions

530×325×325mm (20.87×12.8×12.8 inches)

Ultrasonic Frequency

40 KHz (±3%)

Heating Power

600W (Efficient heating system)

Temperature Range

20-80°C adjustable

Timer Range

1-30 minutes adjustable

Tank Material

304 Stainless Steel (SUS304), 1.5mm thickness

Power Configuration Matrix

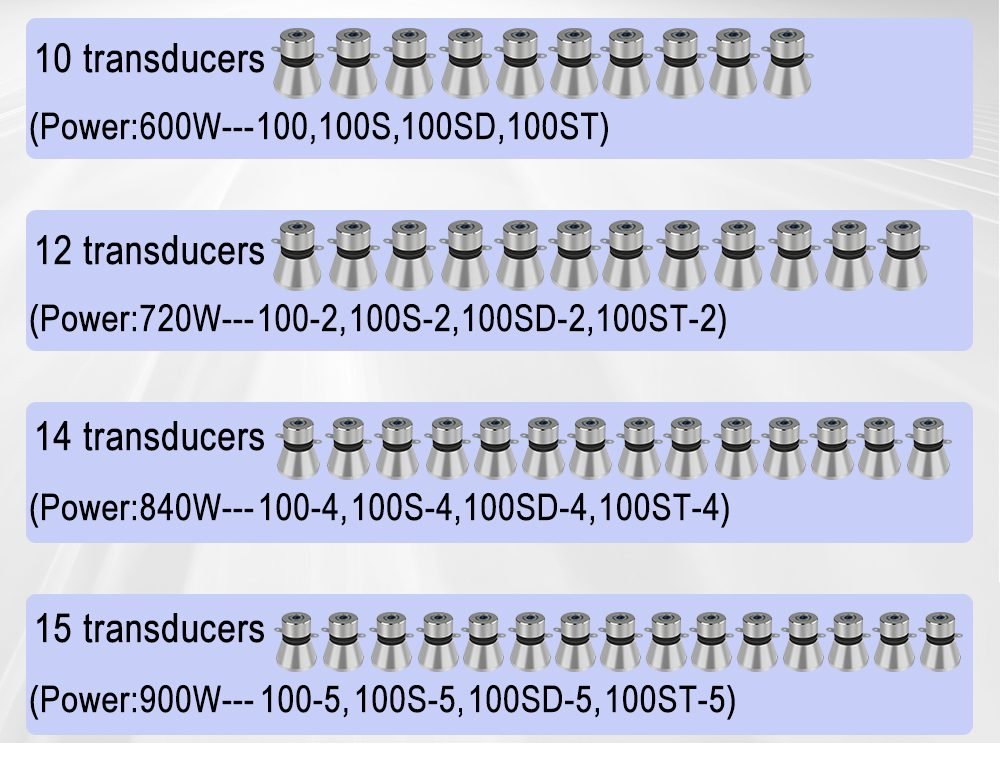

Model Suffix

No. of Transducers

Standard Power

Dual Power Mode(100SD)

Standard models

10 units

600W

300W/600W

-2 Series

12 units

720W

360W/720W

-4 Series

14 units

840W

420W/840W

-5 Series

15 units

900W

450W/900W

Technical Advantages of Ultrasonic Cleaning for Stainless Steel

Efficient Cleaning System

40KHz Industrial Transducers: Each unit equipped with 10-15 industrial-grade transducers

High-frequency Vibration: 40,000 vibrations per second for deep cleaning

Intelligent Power Distribution: 100SD model offers dual power selection

Intelligent Temperature Control

Fast Heating System: 600W heating power for quick temperature rise

Precise Control: Accurate control within 20-80°C range, ±1°C precision

Accelerated Reaction: Heating accelerates chemical reactions for better cleaning

Professional Industrial Design

Large Capacity Design: 30L capacity suitable for batch cleaning

Full Stainless Construction: 304 stainless steel tank and housing

Safety Protection System: Double safety switches, insulated handle, brass drain valve

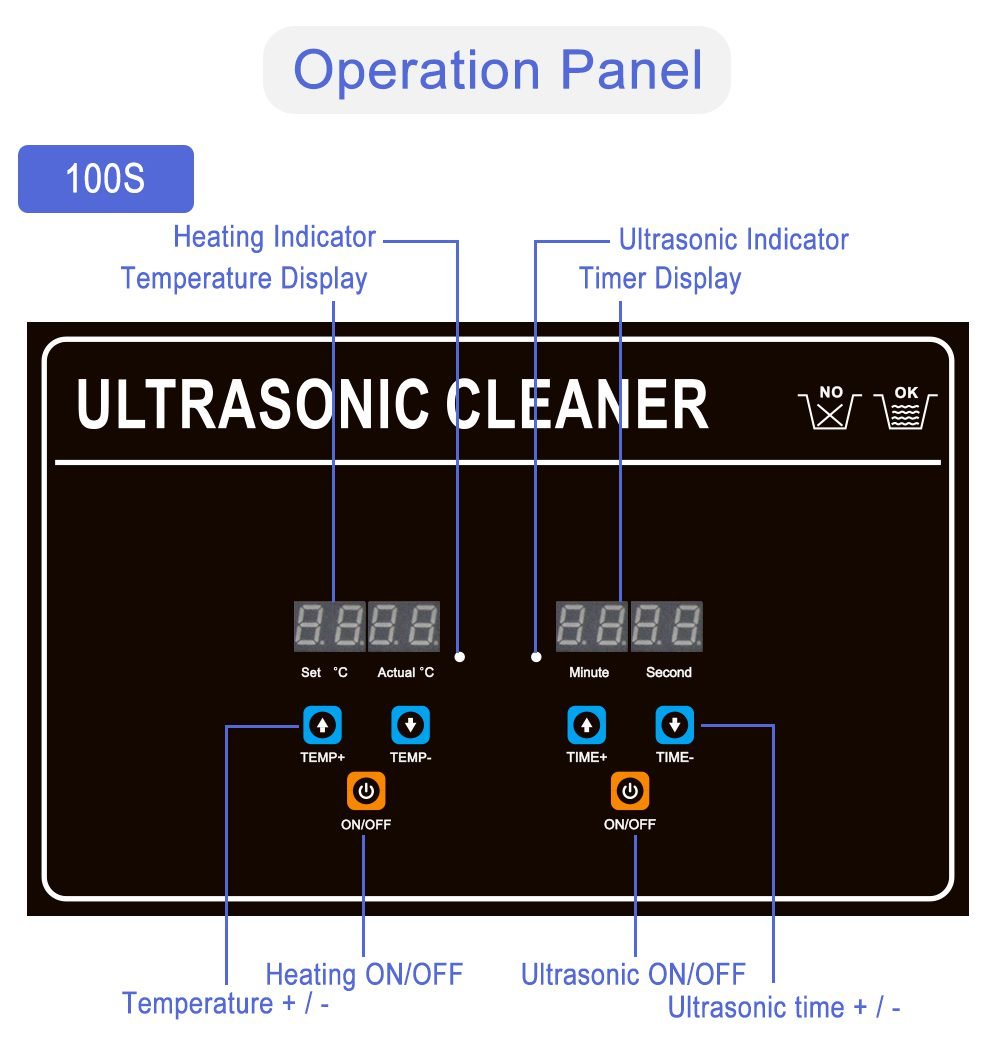

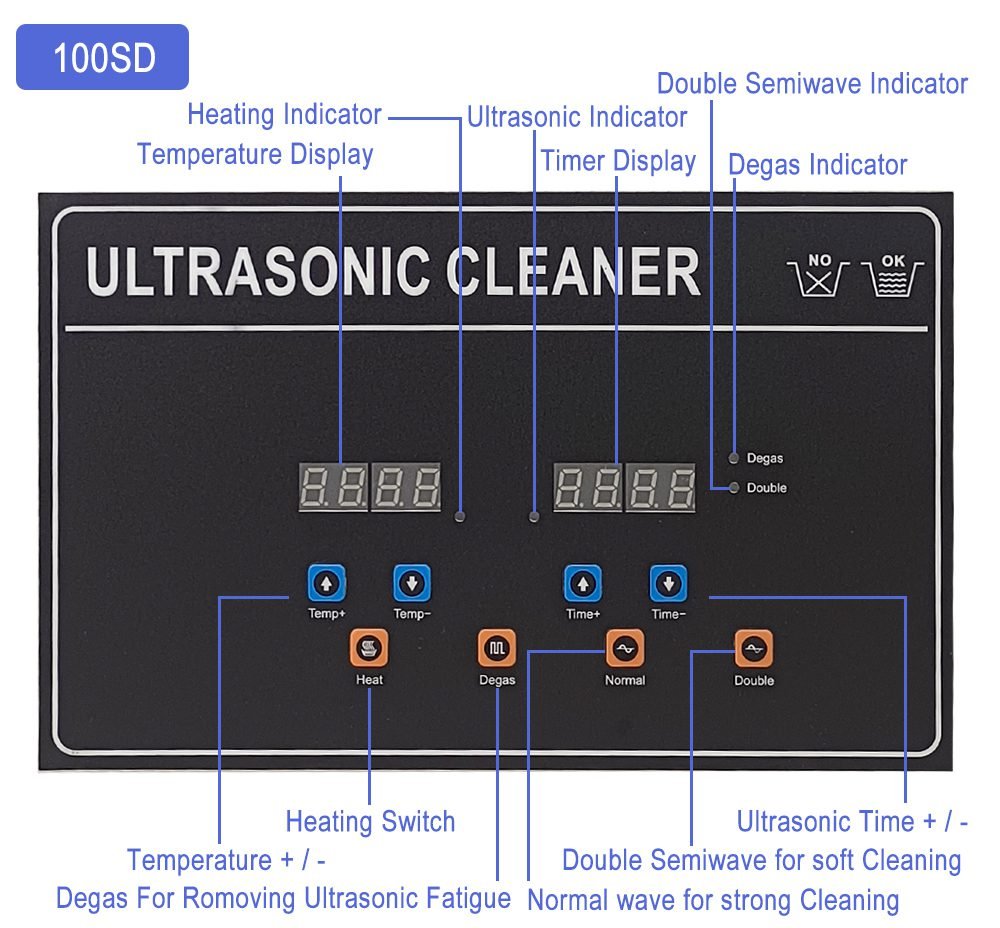

Core Functions of Ultrasonic Cleaning with Degassing Function

Degas Function

Technical Principle: Removes air bubbles from cleaning solution

Application Benefits: Improves ultrasonic transmission efficiency

Operation Method: Press 3 times (100S) or dedicated button (100SD)

Dual Power Mode

300W/600W Selectable: Adapts to different cleaning intensities

Energy Saving Mode: Low power for light contamination

Flexible Application: One-button switching for diverse needs

Double Semi-wave Technology

Gentle Cleaning: Suitable for delicate parts and optical components

Damage Prevention: Reduces ultrasonic impact on sensitive materials

Professional Applications: Labs, jewelry processing, precision instruments

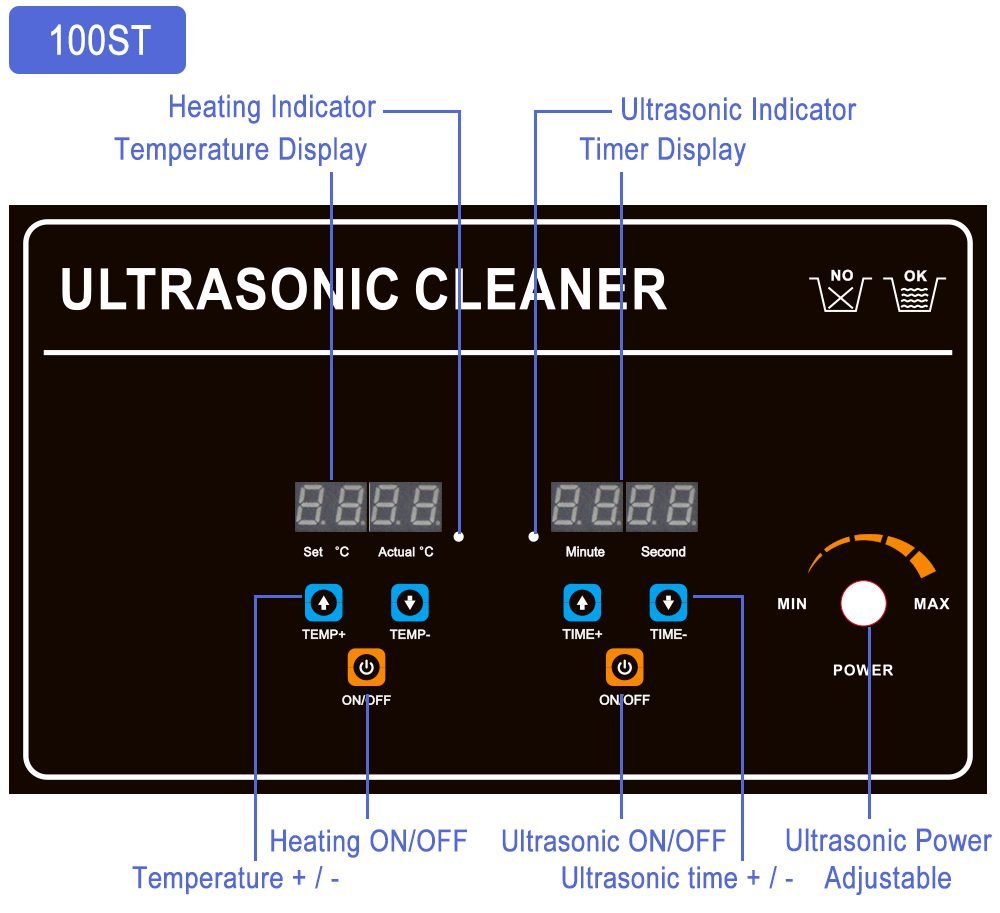

Smart Power Adjustment (100ST Model)

Continuous Adjustment: 0-100% continuously adjustable

Precise Control: Exact adjustment based on material and contamination

Wide Applicability: From delicate electronics to heavy industrial grease

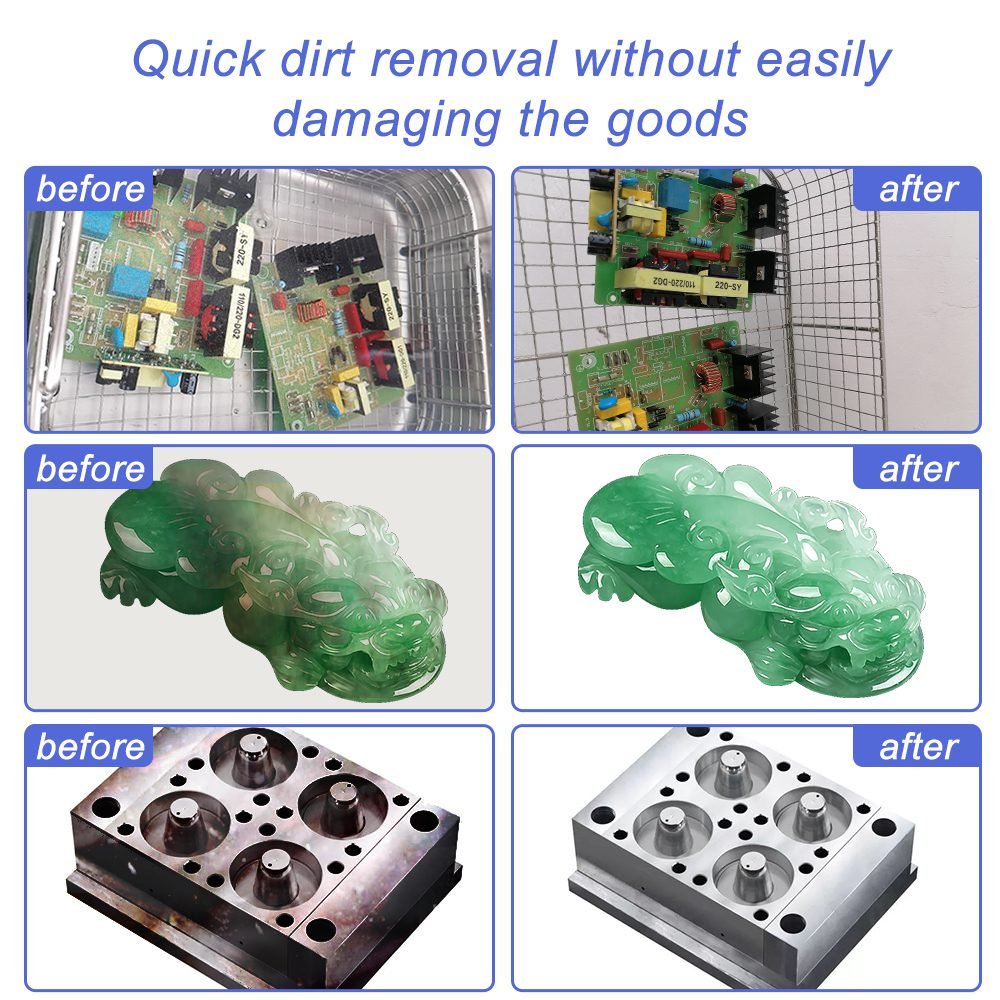

Application Solutions of Microbubble Ultrasonic Cleaning

Mold Cleaning Applications

Cleaning Objects: Injection molds, die-casting molds, stamping molds

Recommended Models: 100SD-4 or 100SD-5 (840W/900W)

Cleaning Results: Complete removal of release agents, grease, carbides

Benefits: Extends mold life by 30%, reduces downtime

Laboratory Research

Cleaning Objects: Labware, glass instruments, sample containers

Recommended Models: 100ST or 100SD (adjustable/dual power)

Cleaning Requirements: Residue-free, high-standard cleaning

Compliance Standards: Meets GLP, GMP laboratory requirements

Electronics Manufacturing

Cleaning Objects: PCB boards, connectors, semiconductor components

Recommended Models: 100S or 100ST (600W-720W)

Cleaning Parameters: 40-50°C, 5-8 minutes, neutral cleaning solutions

Quality Improvement: Reduces short-circuit failures, improves reliability

Automotive Components

Cleaning Objects: Engine parts, transmission components, brake systems

Recommended Models: 100SD-5 (900W dual power)

Cleaning Capability: Handles heavy grease, carbon deposits, metal debris

Efficiency Improvement: 5-10 times faster than traditional cleaning

Medical Equipment

Cleaning Objects: Surgical instruments, dental tools, lab equipment

Recommended Models: 100SD Series (with degas function)

Cleaning Standards: Meets pre-disinfection cleaning requirements

Safety Assurance: No dead-angle cleaning, reduces infection risk

Operation Guide of Ultrasonic Cleaning for Automobiles

Simple Operation Process

Equipment Preparation

Check power plug type

Ensure drain valve is closed

Place on stable work surface

Solution Preparation

Add appropriate amount of water

Add cleaning agent in correct proportion

Fill to recommended liquid level

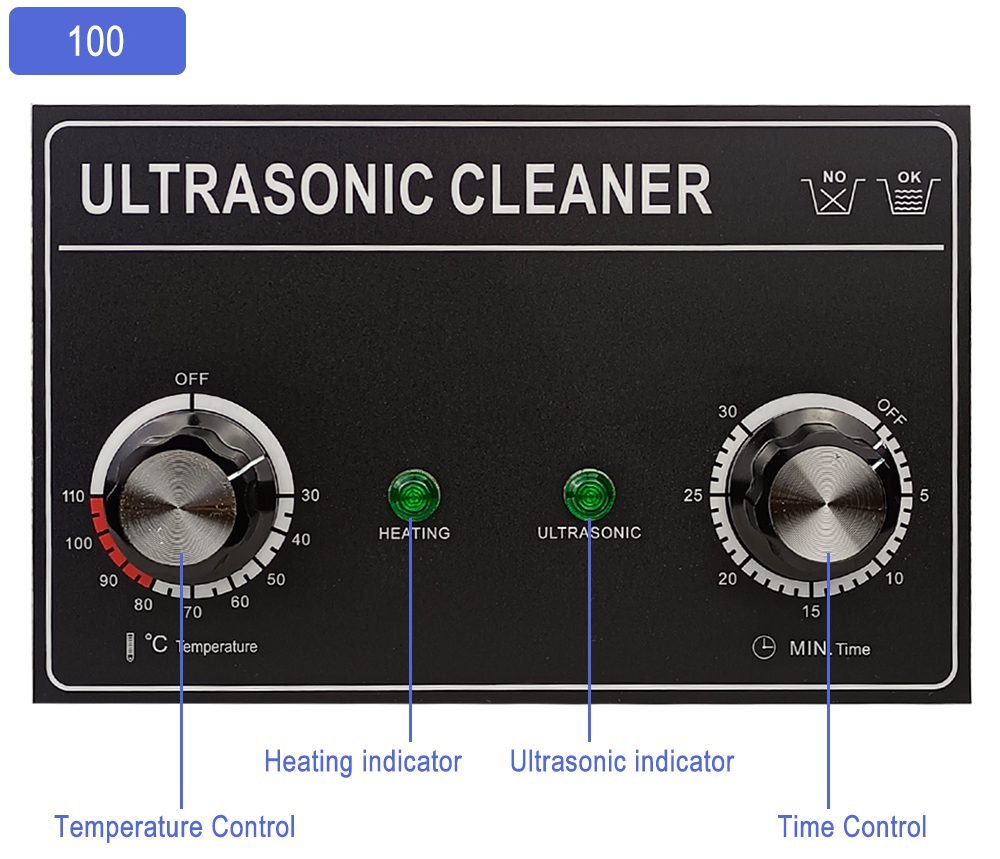

Parameter Setting

Set cleaning temperature

Set cleaning time

Select power mode (if applicable)

Start Operation

Turn on heating function (if needed)

Start ultrasonic cleaning

Monitor operation status

Completion

Automatic stop when timer ends

Remove cleaned workpieces

Drain and clean equipment

Special Function Operation

Degas Function: Run 2-3 minutes degas program before cleaning

Dual Power Switching: Select appropriate power based on workpiece material

Double Semi-wave Mode: Enable when cleaning delicate parts

Power Adjustment: Continuous adjustment via knob on 100ST model

Maintenance of Ultrasonic Cleaning for Metal Parts

Daily Maintenance

After Each Use: Drain cleaning solution, rinse tank with water

Weekly Check: Check drain valve seal, clean filter

Monthly Maintenance: Check transducer status, clean ventilation holes

Regular Maintenance

Quarterly: Comprehensive electrical system inspection

Semi-annually: Professional calibration of temperature control system

Annually: Complete inspection by technical personnel

Troubleshooting

Symptom

Possible Cause

Solution

Slow heating

Heater malfunction

Contact technician

Weak ultrasonic intensity

Transducer issue

Check transducer connections

Inaccurate temperature display

Sensor problem

Recalibrate sensor

Poor drainage

Drain valve blockage

Clean drainage pipes

Customer Value Analysis of Ultrasonic Cleaning with Adjustable Frequency

Value for Distributors

✓ Medium capacity market gap: Fills 30L capacity market void

✓ Clear functional differentiation: Dual power, degas and other features

✓ Wide application coverage: Covers 5 major industrial fields

✓ Complete technical support: Full technical documentation and training

✓ Optimized profit margin: Feature upgrades bring higher added value

Value for End Users

✓ Moderate cleaning capacity: 30L suitable for most industrial applications

✓ Excellent cleaning efficiency: 5-8 times faster than traditional methods

✓ Reduced operating costs: Energy-saving design reduces electricity consumption

✓ Stable cleaning quality: Digital control ensures consistency

✓ Strong durability: Industrial-grade design, long service life

Detailed Technical Parameters of Multi-Function Ultrasonic Cleaner

Performance Parameters

Ultrasonic Generator: Digital pulse generator

Transducer Type: Piezoelectric ceramic transducers

Transducer Bonding: High-temperature welding process

Control System: Microcomputer digital control

Display Accuracy: Temperature ±1°C, Time ±1 second

Power Adjustment Accuracy: 1% increments (100ST model)

Physical Parameters

Net Weight: 25kg

Gross Weight: 28kg

Packaging Dimensions: 550×350×350mm

Operating Noise: <65dB

Protection Rating: IP44 splash-proof design

Operating Environment: 5-40°C, Humidity <80%

Electrical Parameters

Input Voltage: 220V/50Hz or 110V/60Hz optional

Rated Power: Maximum 1500W

Power Cord Length: 1.8 meters standard

Plug Type: Customizable as required

Safety Certifications: CE, RoHS certified

Accessories & Options of Ultrasonic Cleaning for Industrial Gears

Standard Accessories

Stainless steel basket ×1

Drainage pipe ×1

Operation manual ×1

Warranty card ×1

Power cord ×1

Optional Accessories

Special Cleaning Racks: Designed for specific workpieces

Filtration System: Recirculating filtration of cleaning solution

Drying Device: Fast drying after cleaning

Mobile Cart: Easy equipment mobility

Cleaning Agent Kit: Specialized cleaning chemicals

Customization Services

Logo Printing: Custom brand identification on housing

Color Customization: Personalized housing colors

Function Customization: Special function development

Size Adjustment: Non-standard capacity customization

Quality Assurance of Ultrasonic Cleaning for PCB Assembly Lines

Production Quality Control

Raw Material Inspection: All 304 stainless steel materials inspected

Process Control: 38 key quality control points

Aging Test: 48-hour continuous testing for each unit

Final Inspection: 100% functional testing before shipment

Performance Testing Standards

Ultrasonic Intensity Test: Ensure intensity meets standards at all points

Temperature Accuracy Test: Multi-point temperature calibration

Timer Accuracy Test: Time control precision verification

Safety Performance Test: Comprehensive electrical safety testing

After-sales Service Commitment

Warranty Period: 2-year warranty on main components

Response Time: Technical response within 24 hours

Spare Parts Supply: Long-term supply of common spare parts

Technical Support: Lifetime free technical consultation

Send Inquiry

Hot Tags

#30L Ultrasonic Cleaner

#Industrial Ultrasonic Cleaning Equipment

#100 Series Cleaner Dual Power Ultrasonic Cleaning

#Ultrasonic Cleaning Solution Laboratory Instrument Cleaning Equipment

#Electronic Parts Batch Cleaner Automotive Parts Cleaning Equipment

#30L Medical Equipment Sterilization Cleaner

#Heated Ultrasonic Cleaner Digital Control Cleaning Equipment

#Adjustable Power Ultrasonic Cleaning Double Semi-wave Cleaning Technology Degas #Industrial Cleaning Equipment Supplier China Made

#30L Cleaner Export Quality Ultrasonic Equipment