060 Series 15L Industrial Ultrasonic Cleaner | 540W Top Power | Industrial Batch Cleaning System | Professional Manufacturer Solution

Professional manufacturer CleaningSonic offers the CS-060 series 15L super large capacity ultrasonic cleaners, equipped with 6-9 industrial transducers, up to 540W ultrasonic power, 450W heating system. Designed for large-scale industrial manufacturing, medical equipment batch processing, providing complete production line cleaning solutions.

060 Series: Industrial Super High-Power Ultrasonic Cleaning Systems - Ultimate Batch Production Cleaning Solution

Product Description of Cleaning with Ultrasonic Waves

The CleaningSonic 060 Series represents the industrial pinnacle of ultrasonic cleaning technology. Featuring a 15L giant capacity design, equipped with up to 9 industrial-grade transducers, providing an impressive 540W top-tier ultrasonic power and a 450W high-efficiency heating system. This series is specifically designed for large-scale industrial production, medical device batch processing, and heavy-duty parts cleaning, capable of simultaneously handling hundreds of small parts or dozens of large industrial components.

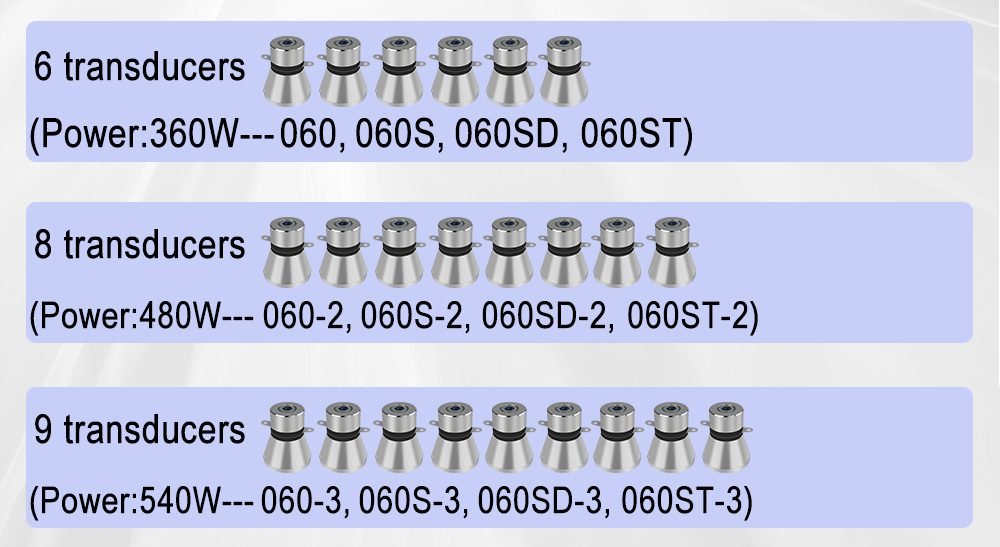

The combination of three power configurations (360W/480W/540W) and four control modes (Basic/Digital/Dual-wave/Adjustable) forms 12 professional configuration choices to meet the special needs of various industrial scenarios. The reinforced cooling system, industrial-grade drain valve, and multiple safety protections ensure reliable operation in 24/7 continuous production environments.

Product Specifications Overview of Ultrasonic Cleaning Equipment

Configuration Level

Basic Model

Digital Control Type

Dual-wave Professional Type

Adjustable Power Type

360W Standard Version

060 (360W)

060S (360W)

060SD (180W/360W)

060ST (0-360W)

480W Enhanced Version

060-2 (480W)

060S-2 (480W)

060SD-2 (240W/480W)

060ST-2 (0-480W)

540W Premium Version

060-3 (540W)

060S-3 (540W)

060SD-3 (270W/540W)

060ST-3 (0-540W)

General Technical Parameters:

Capacity: 15L Industrial Giant Tank

Tank Size: 30×24×15cm (11.81×9.45×5.9 inches)

Unit Size: 32.5×26.5×28cm (12.8×10.43×11.02 inches)

Heating Power: 450W Industrial-grade Heating System

Temperature Range: Adjustable 20-80°C precisely

Timer Range: 1-30 minutes Industrial-grade Timer

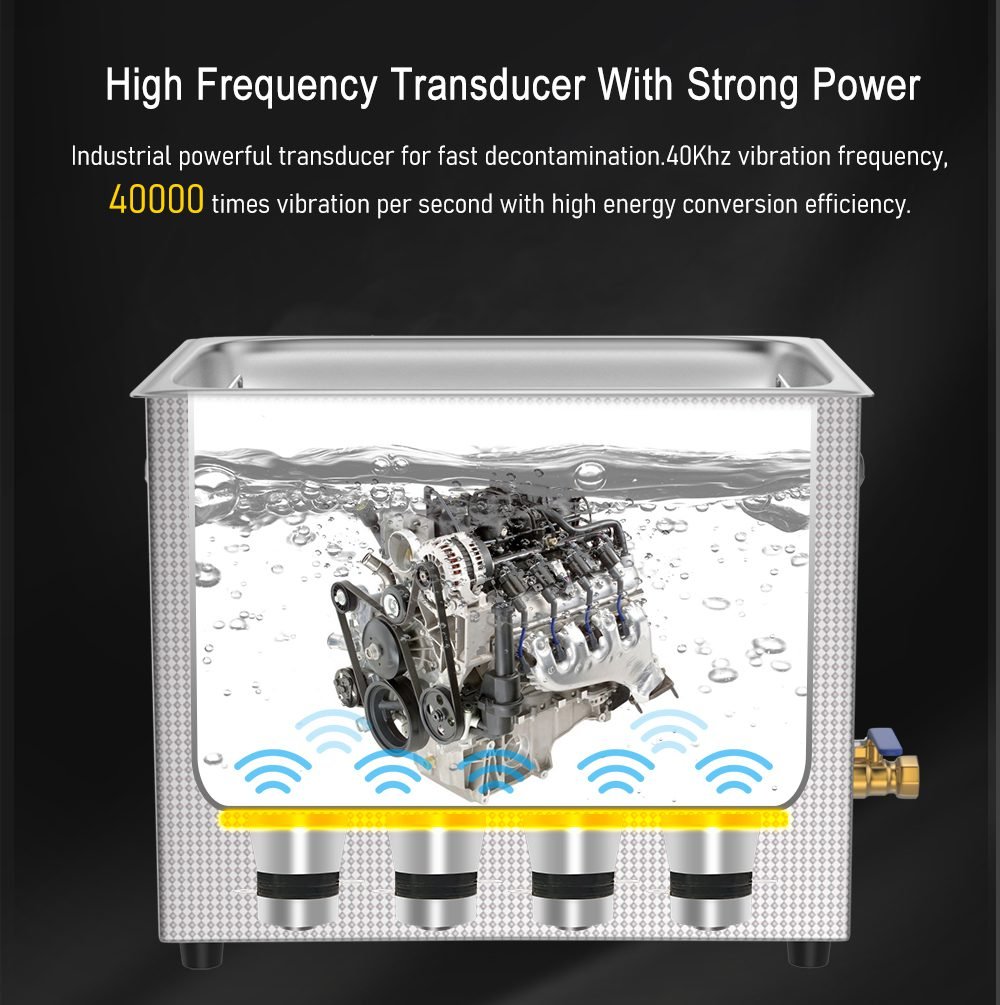

Operating Frequency: 40KHz Industrial Standard Frequency

Transducer Configuration: 6/8/9 pcs × 60W Industrial Transducers

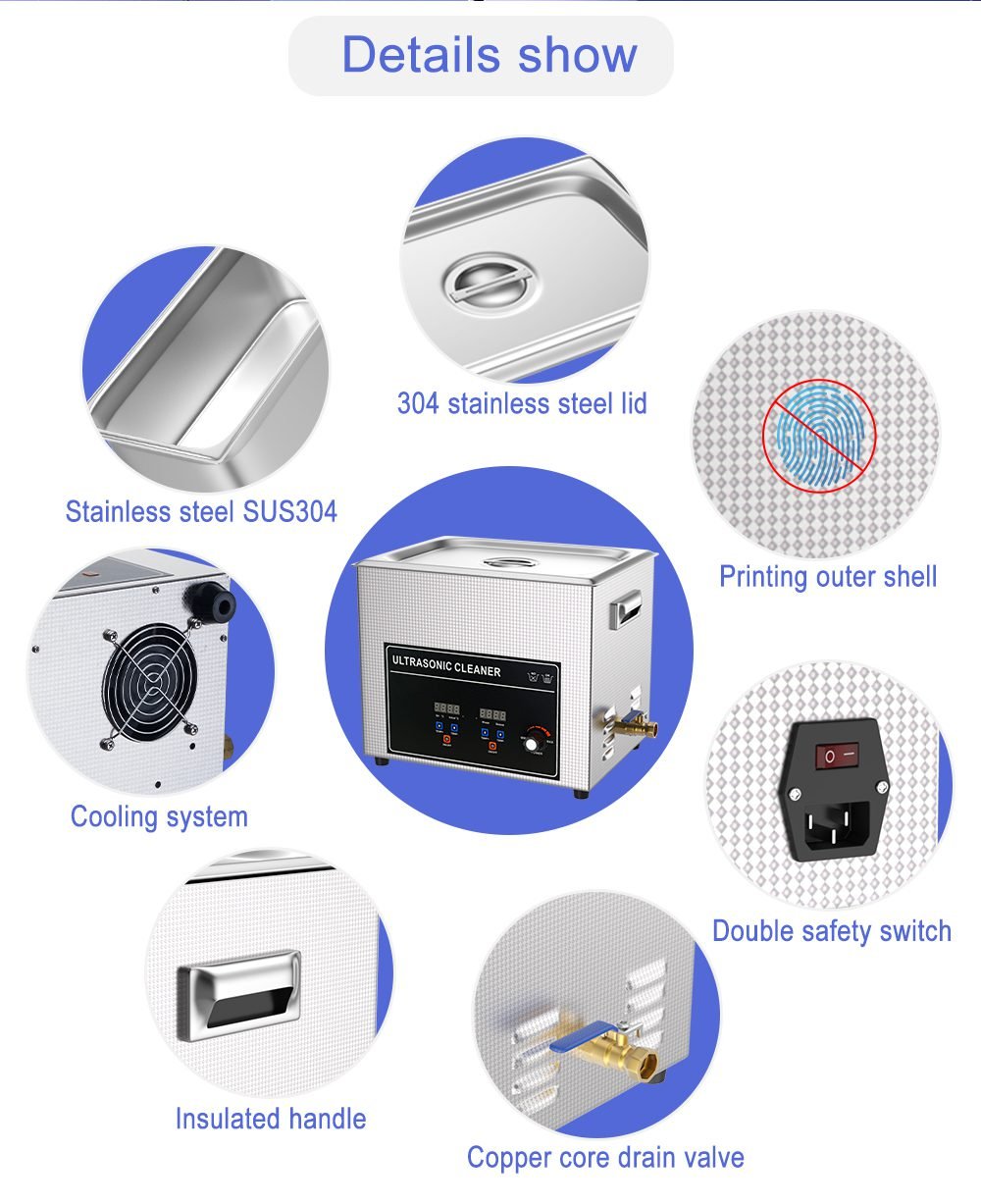

Drainage System: Industrial-grade Copper Core Drain Valve

Cooling System: Triple Fan Intelligent Temperature-controlled Cooling

Power Requirement: AC 220V 50/60Hz 20A Dedicated Circuit

Revolutionary Technical Innovations of Ultrasonic Cleaning Machine

Nine-Transducer Matrix System (540W Premium Version)

Industry-first Layout: 9×60W transducers arranged in a 3×3 matrix pattern, achieving full coverage without dead zones

Intelligent Zone Control: Programmable control of each transducer’s operating state for precise cleaning

Energy Density Breakthrough: 36W/L energy density reaches top industrial cleaning standards

Redundant Fault-tolerant Design: Can continue operation with up to 3 transducer failures, ensuring production continuity

450W Super Heating System

Industrial-grade Heating Modules: Three independent 150W heating modules, controllable by zone

Rapid Heating Technology: Heats 15L solution from room temperature to 80°C in 35 minutes

Intelligent Temperature Control Algorithm: PID + Fuzzy control dual algorithms, temperature fluctuation < ±0.5°C

Energy-saving Operation Mode: Automatically switches to low-power thermal insulation after reaching set temperature

Intelligent Cooling Management System

Three-channel Independent Heat Dissipation: Completely independent heat dissipation for electronic control area, transducer area, heating area

Variable Frequency Intelligent Speed Control: Automatically adjusts fan speed based on load and temperature, saves 30% energy

Heat Pipe Conduction Technology: Vacuum heat pipes rapidly conduct heat, improves heat dissipation efficiency by 50%

Dust-proof Maintenance Design: Removable dust filter screen, supports online cleaning without affecting production

Industrial-grade Structural Design

Thickened Stainless Steel Tank: 2.5mm 304 stainless steel, bearing capacity up to

50kg load capacity

Reinforced Support Frame: Internal rib reinforcement design ensures no deformation during long-term use

Industrial Connection Interfaces: Standard industrial quick-connect interfaces support automation integration

Modular Maintenance Design: All functional modules support quick replacement, reducing downtime

Professional Configuration Details of Ultrasonic Cleaning System

Power Level Selection Guide:

360W Standard Version (6 transducers): Suitable for conventional industry parts batch cleaning

480W Enhanced Version (8 transducers): Suitable for heavily oil-contaminated or structurally complex parts

540W Premium Version (9 transducers): Suitable for highest standard precision cleaning and medical equipment

Control Mode Comparison:

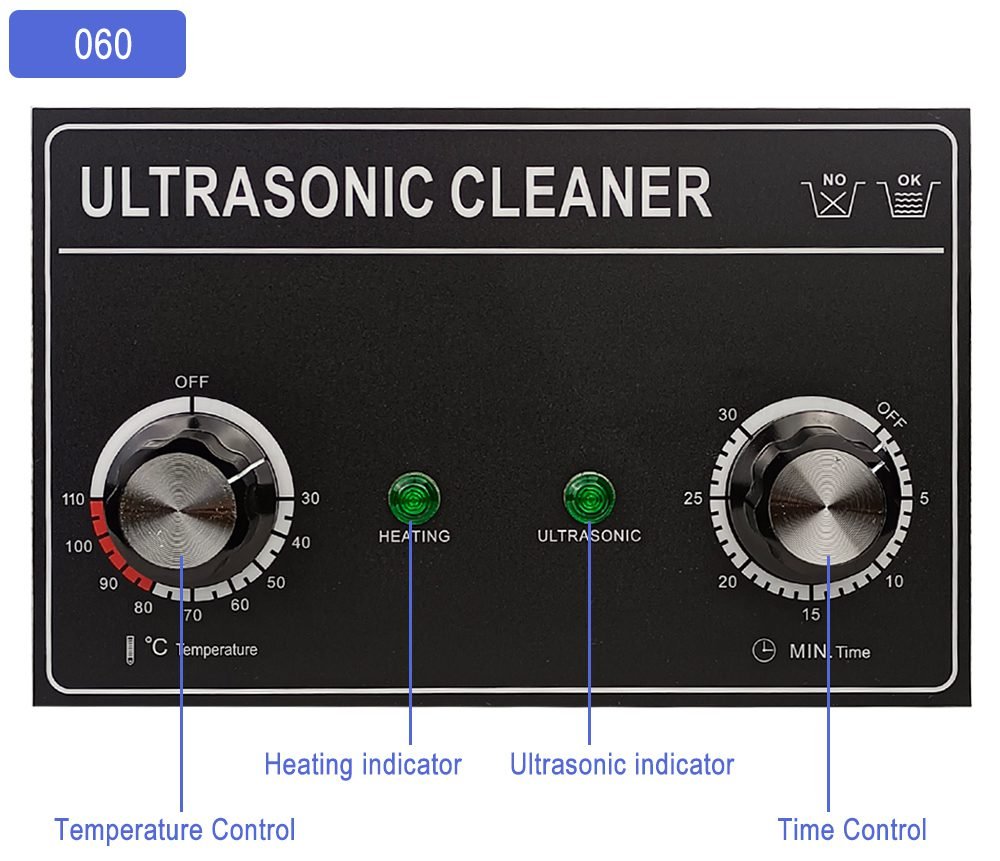

060 Series: Industrial mechanical control, strong anti-interference, suitable for harsh environments

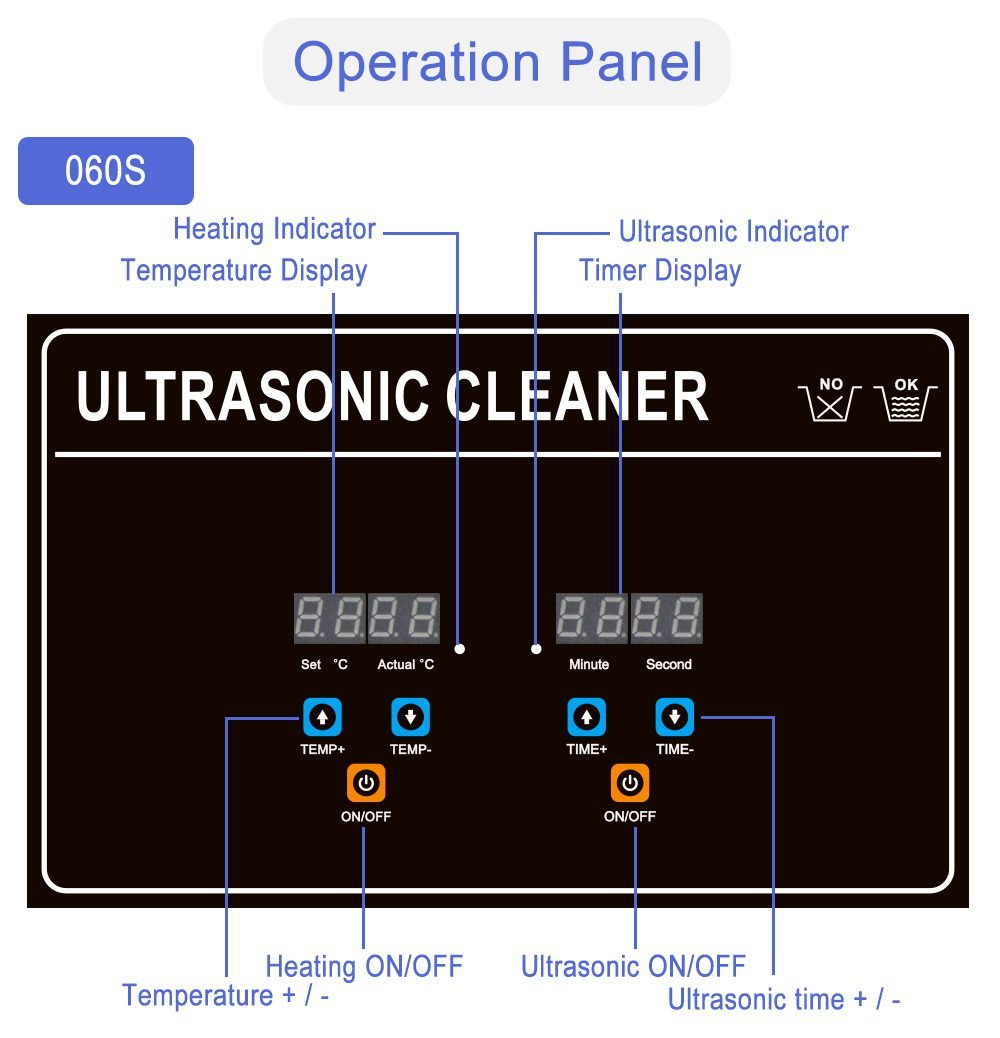

060S Series: Digital intelligent control, suitable for standardized production processes

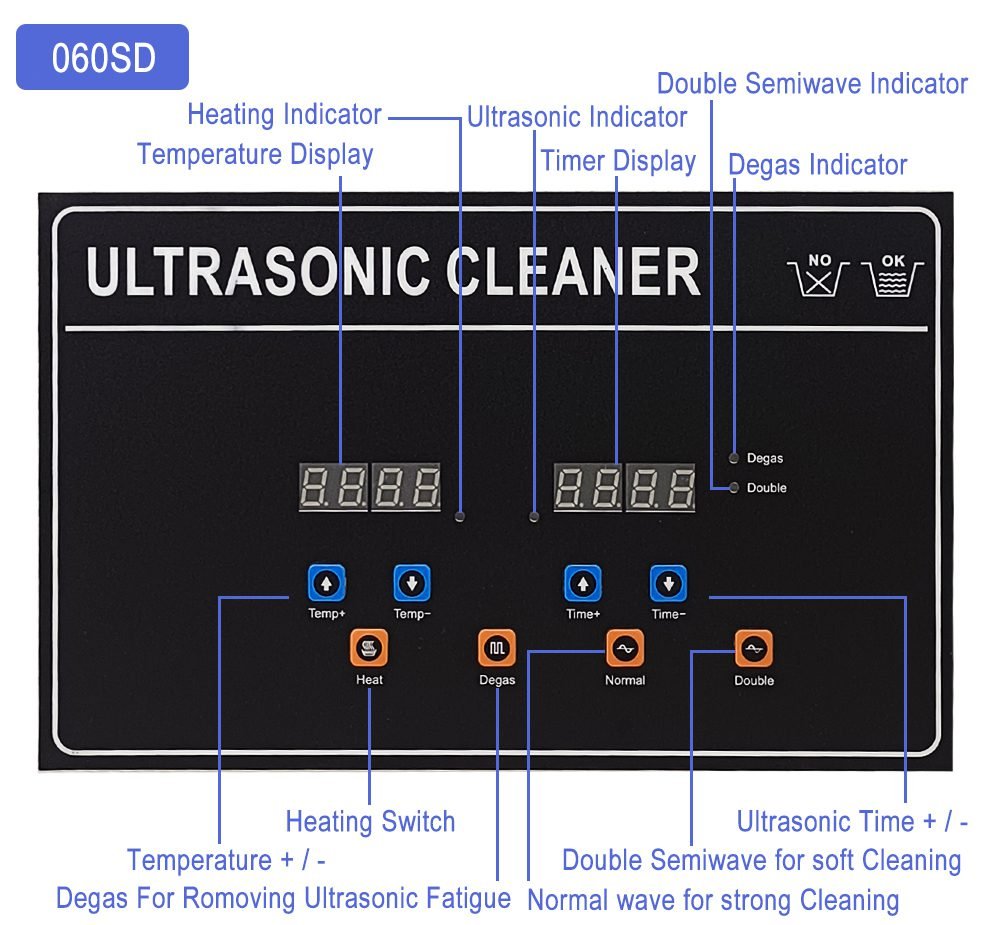

060SD Series: Dual-wave cleaning technology, suitable for mixed materials and precision parts

060ST Series: Stepless power adjustment, suitable for R&D and special process requirements

Application Scenario Configuration Suggestions:

Automotive Manufacturing: 060SD-2 or 060ST-2, for engine and transmission parts

Medical Equipment: 060S-3 or 060ST-3, meets medical certification high-standard requirements

Electronics Manufacturing: 060S-2 or 060SD-2, for PCB boards and precision electronic components

Mold Industry: 060-3 or 060S-3, for large molds and injection molded parts

Full-scenario Industrial Application Solutions of Ultrasonic Cleaning Tank / Ultrasonic Tank

Automotive Manufacturing Batch Cleaning:

Engine Production Line: Mass continuous cleaning of cylinder blocks, cylinder heads, crankshafts

Transmission Manufacturing: Deep oil cleaning of gears, clutches, drive shafts

Component Suppliers: Standardized cleaning of brake systems, suspension parts

Remanufacturing Plants: Large-scale cleaning for refurbishing old parts

Aerospace Precision Cleaning:

Engine Manufacturing: Precision cleaning of turbine blades, combustion chamber components

Airframe Components: Degreasing and pre-treatment of aviation aluminum alloy structures

Landing Gear Systems: Deep cleaning of hydraulic components and bearings

Maintenance & Overhaul: Maintenance and overhaul cleaning of aircraft parts

Medical Equipment Large-scale Processing:

Surgical Instrument Center: Centralized batch pre-sterilization cleaning of surgical instruments

Implant Manufacturing: Large-scale production cleaning of artificial joints, orthopedic implants

Diagnostic Equipment: Professional cleaning of medical imaging equipment components

Dental Instruments: Batch pre-disinfection processing of dental handpieces and tools

Electronics Manufacturing High-end Applications:

Semiconductor Front-end: Particle control cleaning of wafer carriers, process chamber components

High-end Circuit Boards: Precision cleaning of military, aerospace-grade PCB boards

Optical Devices: Dust-free cleaning of camera modules, laser devices

New Energy Equipment: Cleaning maintenance of battery production line molds and tools

Heavy Industry Special Applications:

Mold Manufacturing: Regular deep cleaning of injection molds, die-casting molds

Hydraulic Systems: Oil and particle cleaning of hydraulic valves, cylinders

Power Equipment: Maintenance cleaning of power generation equipment parts, insulated tools

Shipbuilding: Pre-Anti-corrosion treatment cleaning of marine equipment, offshore engineering parts

Send Inquiry

Hot Tags

#15LUltrasonicCleaner #540WTopPower #IndustrialBatchCleaningSystem #NineTransducerCleaner

#MedicalEquipmentBatchProcessing #AutoPartsCleaningLine #IndustrialGradeCleaning #ProfessionalManufacturer

#060UltrasonicCleaner #AerospaceCleaning #SemiconductorManufacturingCleaning #MoldDeepCleaning

#AutomatedCleaningIntegration #ProductionLineCleaningSolutions #HeavyIndustrialCleaning #GlobalTechnicalService