031 Series 6.5L Extra Large Capacity Ultrasonic Cleaner | Industrial Grade Deep Cleaning Equipment | 180W Power 300W Heating System | Professional Manufacturer

Professional manufacturer CleaningSonic offers 031 series 6.5L extra large capacity ultrasonic cleaners with copper core drain valve, enhanced cooling system, dual-wave cleaning technology. Designed for medical equipment, industrial parts, laboratory batch cleaning. Global plug customization & OEM/ODM services available.

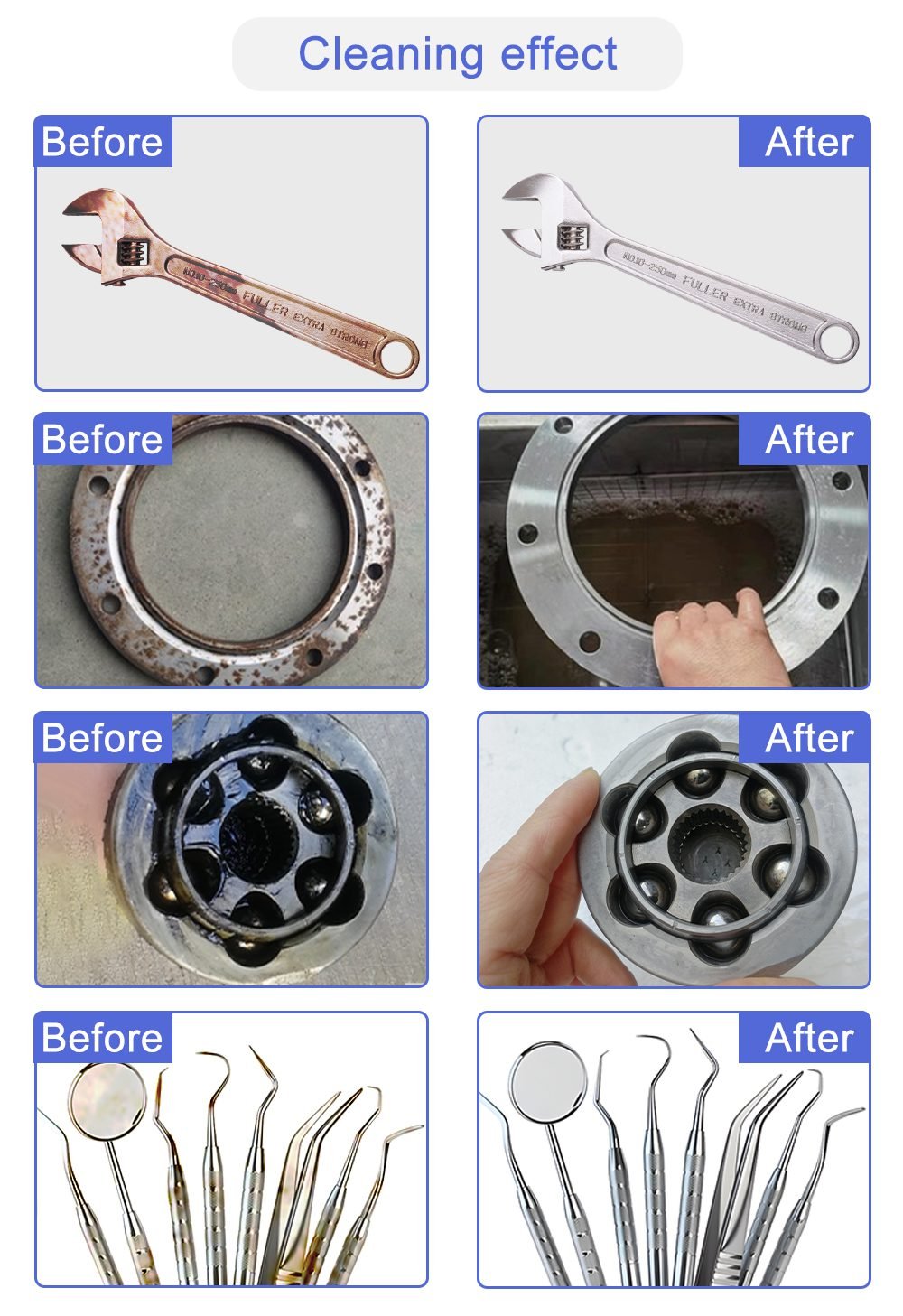

031 Series: Extra Large Capacity Professional Ultrasonic Cleaners - Industrial Grade Deep Cleaning Solutions

Product Description of Ultrasonic Cleaner with Knob

The CleaningSonic 031 Series Ultrasonic Cleaners represent our top-tier technology in large capacity professional cleaning equipment. Featuring a 6.5L extra large deep tank design that accommodates large medical instruments and industrial parts, equipped with 180W powerful ultrasonic energy and 300W efficient heating system. Exclusive copper core drain valve design and enhanced cooling system ensure long-term stable operation and convenient maintenance. Dual-wave cleaning technology provides both intensive and gentle cleaning modes, meeting fine cleaning requirements for different materials.

This series offers four professional configurations, from basic knob control to intelligent adjustable power models, meeting customized needs of various professional venues. Global multi-standard plug adaptation ensures plug-and-play operation worldwide. We provide comprehensive OEM customization services for global distributors.

Product Specifications of Professional Industrial Auto Cleaning Machine for Carburetor Repairing Tools Parts Instrument

Model

031

031S

031SD

031ST

Capacity

6.5L

6.5L

6.5L

6.5L

Ultrasonic Power

180W

180W

90W/180W Dual Power

0-180W Stepless Adjustable

Transducer Config

3×60W

3×60W

3×60W

3×60W

Heating Power

300W

300W

300W

300W

Frequency

40KHz

40KHz

40KHz

40KHz

Temp. Range

20-80°C

20-80°C

20-80°C

20-80°C

Timer Range

1-30 min

1-30 min

1-30 min

1-30 min

Control Type

Knob Mechanical Control

Digital Intelligent Control

Digital Intelligent Control

Digital Intelligent Control

Special Features

Basic Cleaning

Digital Control + Degas

Dual-wave Cleaning + Degas

Stepless Power Adjustment

Drain System

Copper Core Drain Valve

Copper Core Drain Valve

Copper Core Drain Valve

Copper Core Drain Valve

Cooling System

Enhanced Air Cooling

Enhanced Air Cooling

Enhanced Air Cooling + Smart Temp Control

Enhanced Air Cooling + Smart Temp Control

Tank Size

11.81 x 5.9 x 5.9 inch

11.81 x 5.9 x 5.9 inch

11.81 x 5.9 x 5.9 inch

11.81 x 5.9 x 5.9 inch

Unit Size

12.8 x 7.09 x11.02 inch

12.8 x 7.09 x11.02 inch

12.8 x 7.09 x11.02 inch

12.8 x 7.09 x11.02 inch

Core Technical Innovations of Digital Sonic Cavitation Cleaner with Heater

Extra Large Deep Tank Design

6.5L Industry-leading Capacity: Specially deepened tank design cleans instruments up to 30cm long

Optimized Length-Depth Ratio: 11.81″ length with 5.9″ depth perfectly accommodates surgical instruments, long-handle tools

Three-dimensional Cleaning Coverage: Three transducers arranged Three-dimensional layout ensures uniform cleaning in deep tank

Copper Core Drain Valve System

Durable Copper Valve Core: 5x more durable than plastic valves, excellent corrosion resistance

Fast Drain Design: Large diameter drain outlet empties 6.5L capacity within 60 seconds

Leak-proof Sealing Technology: Dual sealing ring design ensures no leakage during long-term use

Easy Maintenance: Modular design allows simple and quick replacement

Enhanced Cooling System

Dual Fan Intelligent Cooling: Automatically adjusts fan speed based on temperature, energy-saving and quiet

Heat Pipe Conduction Technology: Efficiently conducts residual heat from heating system, improves cooling efficiency by 40%

Continuous Operation Capability: Supports 8+ hours uninterrupted operation, suitable for batchwork scenario

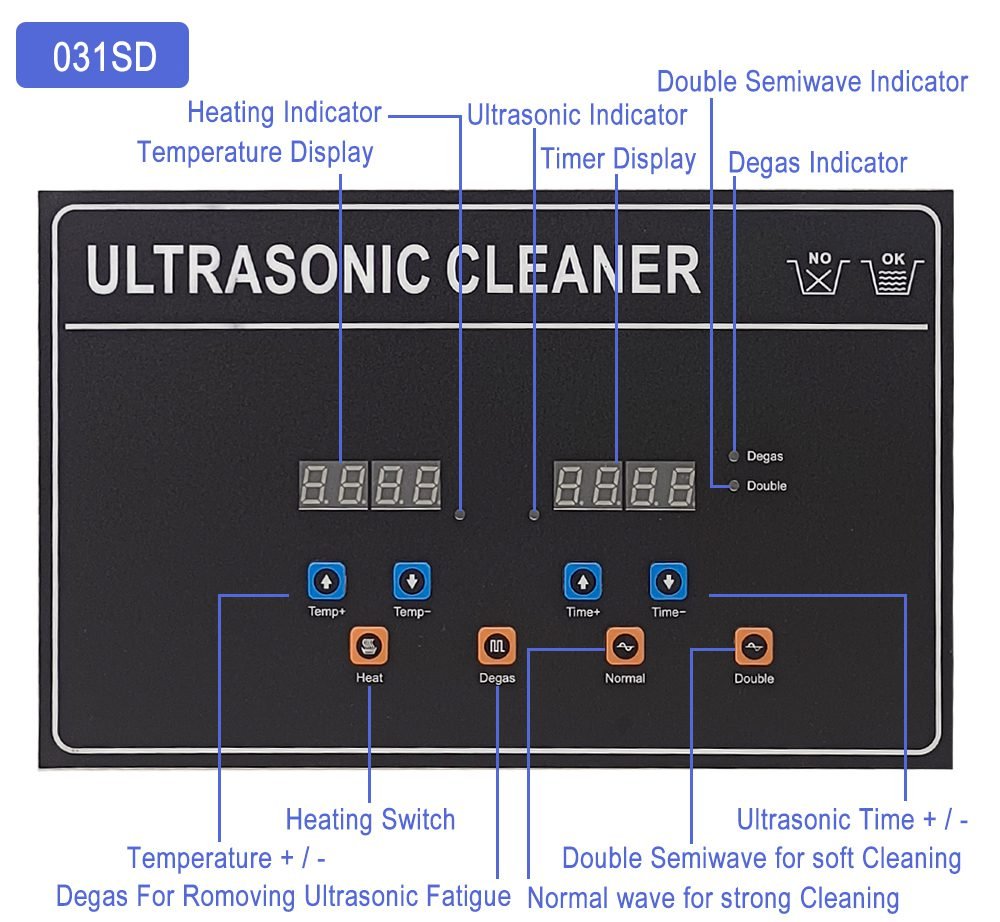

Dual-wave Cleaning Technology (031SD)

Intelligent Wave Switching: One-touch switching between standard wave (intensive cleaning) and semi-wave (gentle cleaning)

Adaptive Cleaning Algorithm: Automatically optimizes wave combination based on set power and time

Fatigue Elimination Technology: Regular wave switching extends transducer lifespan by 30%

Professional Functions Detailed of Ultrasonic Cleaner Machine with 304 Stainless Steel Tank

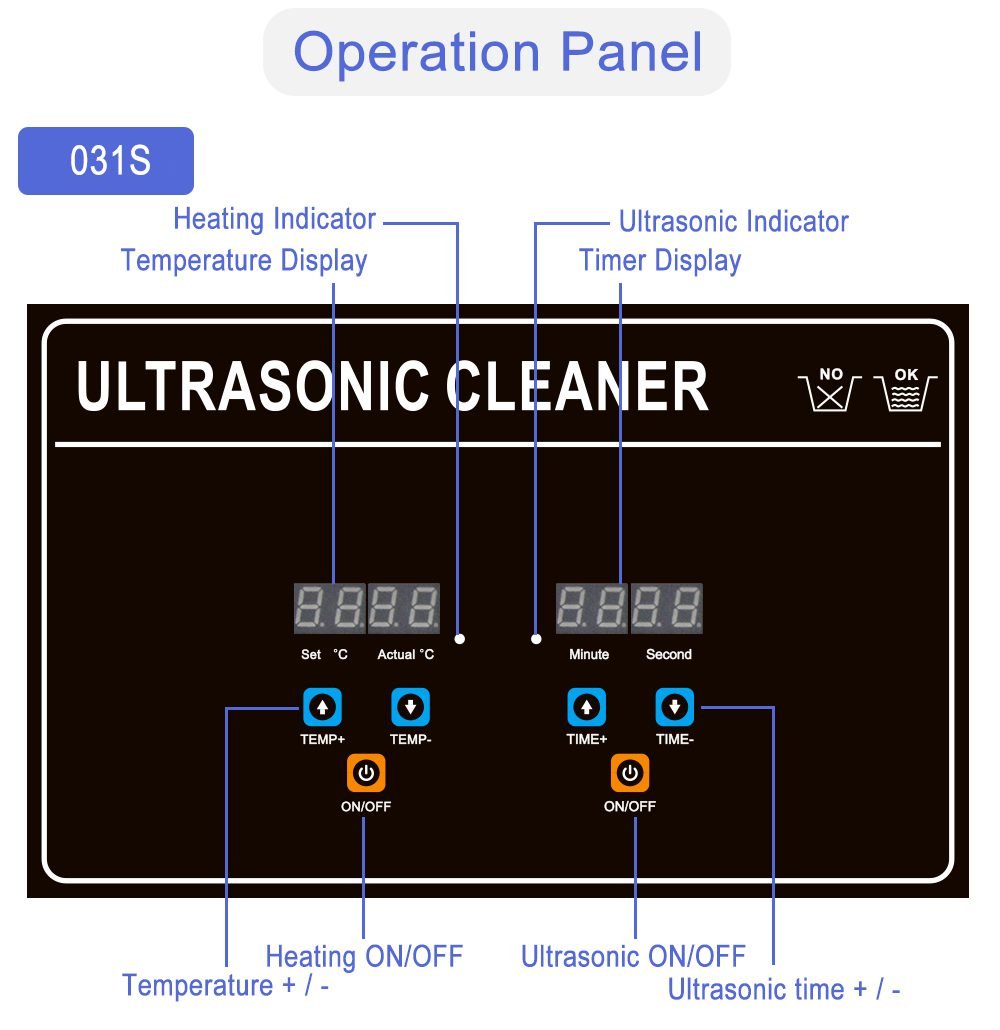

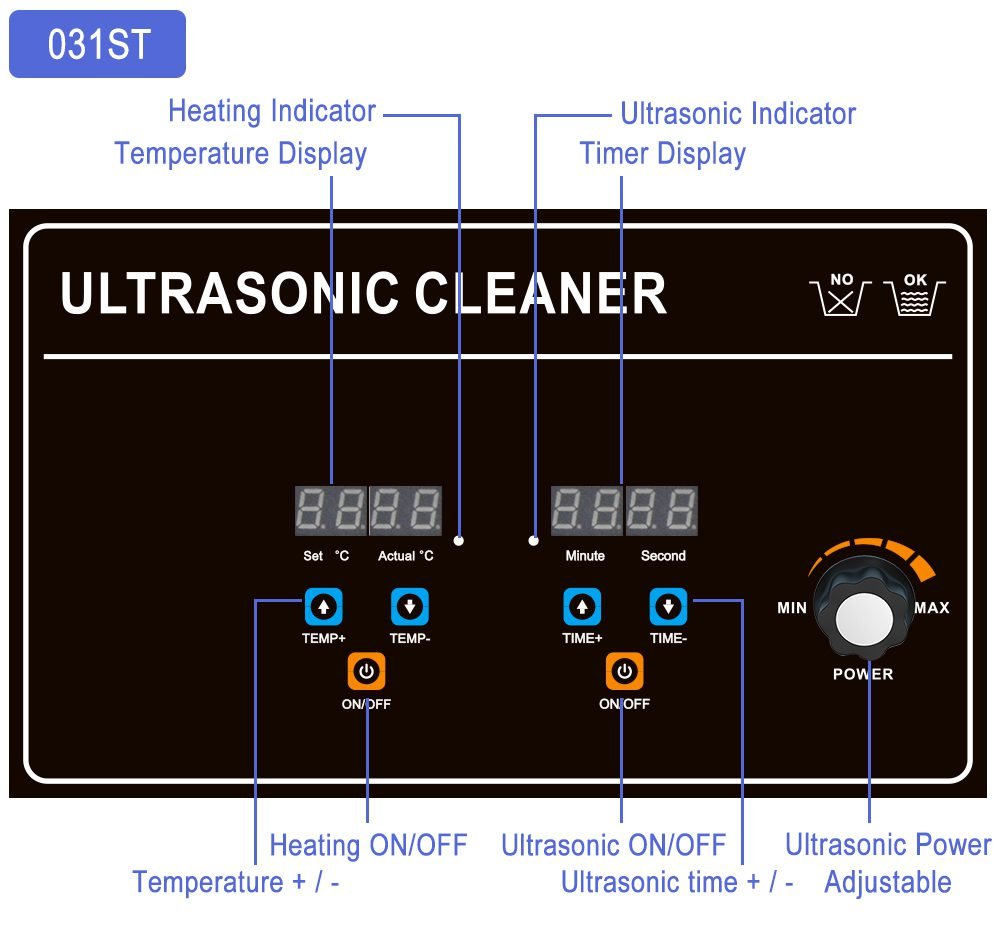

Operation Control Systems:

031 Basic Model: Mechanical knob control, suitable for harsh industrial environments

031S Standard Model: Digital temperature control + timer, suitable for常规医疗 laboratories

031SD Professional Model: Dual-wave cleaning + degas function, suitable for mixed material cleaning

031ST Premium Model: Stepless power adjustment, suitable for precision instruments and special process

Safety Protection Systems:

Dual Safety Switches: Prevent accidental startup, comply with medical equipment safety standards

Overheat Auto Protection: Automatic power-off when temperature exceeds 85°C, preventsequipment damaged

Dry-run Protection: Automatically stops heating when liquid level is too low, extends heating element lifespan

Leakage Protection: Complies with international electrical safety standards, ensures operator safety

Ergonomic Design Features:

Insulated Heat-proof Handle: Wider design allows easy operation even with gloves

Multi-angle Viewing Window: High-transparency material provides clear monitoring of deep tank bottom

Adjustable Non-slip Feet: Four Independently adjustable corners adapt to uneven work surfaces

Cable Management System: Built-in cable channels keep work area tidy and safe

Application Scenarios Deep Expansion of Dual Modes & LED Display - for Jewelry, Eyeglasses, Watches, Dentures, Retainers & More

Medical Equipment Deep Cleaning:

Surgical Instrument Central Processing: Orthopedic instruments, endoscopes, laparoscopes and other long-handle instruments

Dental Equipment Batch Processing: Deep cleaning of dental handpieces, implant instruments, orthodontic tools

Rehabilitation Equipment Maintenance: Regular deep cleaning of physiotherapy equipment, rehabilitation devices

Testing Equipment Cleaning: Precision components of automated testing instruments like sampling needles, reaction cups

Industrial Manufacturing Special Applications:

Aircraft Engine Parts: Cleaning of complex structure parts like turbine blades, fuel nozzles

Automotive Transmission Systems: Batch cleaning of large parts like gearbox gears, drive shafts

Mold Deep Hole Cleaning: Cleaning of cooling water holes and ejector pin holes in injection molds, die-casting molds

3D Printing Post-processing: Support structure removal and surface cleaning of large metal 3D printed parts

Research Institution Professional Applications:

Large Experimental Apparatus: Cleaning of reactor accessories, distillation equipment, extraction devices

Field Sampling Equipment: Deep cleaning of geological sampling tools, environmental monitoring instruments

Marine Research Equipment: Salt removal from underwater detection equipment, seawater samplers

Agricultural Research Instruments: Cleaning of soil analysis equipment, plant sample processing tools

Special Industry Professional Services:

Fire Equipment Maintenance: Deep cleaning and disinfection of respirator masks, firefighting equipment

Food Processing Equipment: Food-grade cleaning of food production molds, filling equipment

Printing Industry Applications: Ink residue removal from printing rollers, anilox rollers

Electrical Equipment Maintenance: Cleaning and maintenance of insulated tools, power distribution equipment

Technical Parameter Comparison Analysis of Ultrasonic Retainer Cleaner Machine

Performance Dimension

031 Series

Industry Average

Competitive Advantage

Max Cleaning Length

300mm

200-250mm

20-50% Increase

Heating Efficiency

18 min (room temp→80°C)

25-30 minutes

40% Time Saving

Continuous Operation Time

8+ hours

4-6 hours

33% Stability Improvement

Drain Speed

60 seconds for 6.5L

90-120 seconds

50-100% Efficiency Increase

Energy Efficiency

0.85 kW·h/cycle

1.2-1.5 kW·h

30-45% Energy Saving

Maintenance Cycle

1000 hours

500-800 hours

25-50% Maintenance Cost Reduction

Economic Benefit Analysis of Dental Cleaning Pod for Denture, Mouth Guard, Night Guard, Aligner, Braces, Toothbrush

Investment Cost Analysis:

Single Unit Purchase Cost: 50-60% savings compared to European similar products

Installation & Commissioning Cost: No professional installation needed, plug-and-play

Training Cost: Multi-language video tutorials reduce training time by 70%

Operating Cost Advantages:

Energy Cost: Intelligent power adjustment reduces energy consumption by 35%

Cleaning Solution Cost: Optimized tank design reduces solution usage by 25%

Labor Cost: Batch processing capability reduces manual input by 60%

Maintenance Cost: Modular design reduces annual maintenance cost by 40%

Investment Return Period:

Production Efficiency Improvement: Batch processing capability increases cleaning efficiency by 300%

Quality Control: Standardized cleaning process improves product qualification rate to 99.5%

Business Expansion: Can undertake external high-end cleaning services, annual revenue growth potential 30-50%

Asset Depreciation: 5-year depreciation cycle, annual cost only the purchase price 20%

Quality Certification System of Denture Cleaner with Digital Timer

International Certification Standards:

ISO9001:2015 Quality Management System

ISO13485 Medical Device Quality Management System (optional)

European certifications: CE, RoHS, REACH

North American electrical safety certifications: UL/cUL (optional)

Manufacturing Quality Control:

Material Traceability System: Each key component has unique traceability code

Production Process Monitoring: 36 quality control points with full data recording

Factory Testing Standards: 72-hour aging test + full function test + safety test

Packaging & Shipping Standards: Customized packaging solutions ensure international transportation safety

Technical Service Support:

Installation Guidance: Multi-language installation videos and graphic guide

Operation Training: Online training courses + on-site guidance (optional)

Remote Diagnostics: Supports remote Trouble shooting and software upgrades

Parts Supply: Global parts network ensures 10-year parts availability

Regular Maintenance: Provides annual maintenance plans and preventive maintenance services

Customization Service Packages of Ultrasonic Cleaner

Basic Customization Services:

Brand Identification: Front panel LOGO printing, control panel brand customization

Exterior Colors: Multiple standard colors available, supports Pantone color card customization

Packaging Design: Full set customization of brand packaging box, manual, warranty card

Power Configuration: Global major country standard plugs available

Function Customization Services:

Special Frequencies: Can customize special frequencies like 28KHz, 68KHz based on cleaning materials

Power Adjustment: Adjust ultrasonic power and heating power according to customer requirements

Control Interface: Multi-language operation interface, supports special industry terminology customization

Software Functions: Customized cleaning programs, data recording and reporting functions

Deep Cooperation Packages:

Joint R&D: Co-develop special model based on specific industry needs

Private Molds: Develop special model and components for high-volume customers

Technical Training: Provide In-depth training on ultrasonic cleaning technology for customers

Market Support: Joint marketing, exhibition support, technical seminar cooperation

Industry Solution Packages:

Medical Equipment Cleaning Package:

031SD main unit +special instrument basket + medical cleaning solution + water filter

Supporting services: Operation training + Cleaning process design + Regular calibration

Industrial Manufacturing Cleaning Package:

3×031ST units forming production line + multi-size cleaning baskets + industrial cleaning solution

Supporting services: Production line layout design + Maintenance training + Fast response service

Laboratory Research Cleaning Package:

2×031S + 1×031SD + laboratory special accessories

Supporting services: SOP development + Data analysis + Annual upgrade service

Distributor Support Package:

Mixed model purchase discounts + Marketing material support + Technical training

Inventory management advice + After-sales service system establishment support

Send Inquiry

Hot Tags

#6.5LUltrasonicCleaner #ExtraLargeCapacityCleaning #MedicalInstrumentCleaner #IndustrialDeepCleaning

#CopperCoreDrainValveCleaner #DualWaveCleaningTechnology #ProfessionalGradeCleaning #OEMCustomSolutions

#031UltrasonicCleaner #SurgicalInstrumentCleaning #IndustrialPartsBatchProcessing #SmartTemperatureControl

#EnhancedCoolingSystem #SteplessPowerAdjustment #GlobalVoltageAdaptation #ProfessionalManufacturerDirect