040 Series 10L Super Power Ultrasonic Cleaner | 360W Top Power Configuration | Industrial Batch Cleaning Equipment | Professional Manufacturer

Professional manufacturer CleaningSonic offers 040 series 10L super power ultrasonic cleaners with 4-6 industrial transducers, up to 360W ultrasonic power. Designed for large-scale industrial parts, medical equipment batch cleaning. Global plug customization & complete OEM/ODM solutions available.

040 Series: Super Power Professional Ultrasonic Cleaners - Ultimate Industrial Batch Cleaning Solution

Product Description of Ultrasonic Retainer Cleaner Machine

The CleaningSonic 040 Series represents the pinnacle of ultrasonic cleaning technology. Featuring a 10L extra large capacity industrial-grade tank equipped with up to 6 industrial transducers providing top-level 360W ultrasonic power. This series is specifically designed for challenging, high-volume professional cleaning scenarios, capable of processing numerous industrial parts or medical instruments simultaneously, significantly improving cleaning efficiency and production capacity.

Four professional configurations (040 Basic, 040S Standard, 040SD Dual-wave, 040ST Adjustable) meet special needs across different industries. Enhanced cooling system, copper core drain valve, and professional safety protection design ensure Equipment stability and reliability during prolonged high-intensity use. We provide deep customization OEM services for global industrial customers and distributors.

Product Specifications of Industrial Cleaning Machine High Efficiency Industrial

Specification

040/040-2

040S/040S-2

040SD/040SD-2

040ST/040ST-2

Model

040(240W)/040-2(360W)

040S(240W)/040S-2(360W)

040SD(240W)/040SD-2(360W)

040ST(240W)/040ST-2(360W)

Capacity

10L

10L

10L

10L

Ultrasonic Power

240W(4 transducers)/360W(6 transducers)

240W(4 transducers)/360W(6 transducers)

240W(4 transducers)/360W(6 transducers)

240W(4 transducers)/360W(6 transducers)

Transducer Config

4×60W/6×60W

4×60W/6×60W

4×60W/6×60W

4×60W/6×60W

Heating

500W

500W

500W

500W

Frequency

40KHz

40KHz

40KHz

40KHz

Timer Range

1-30 min

1-30 min

1-30 min

1-30 min

Temp. Range

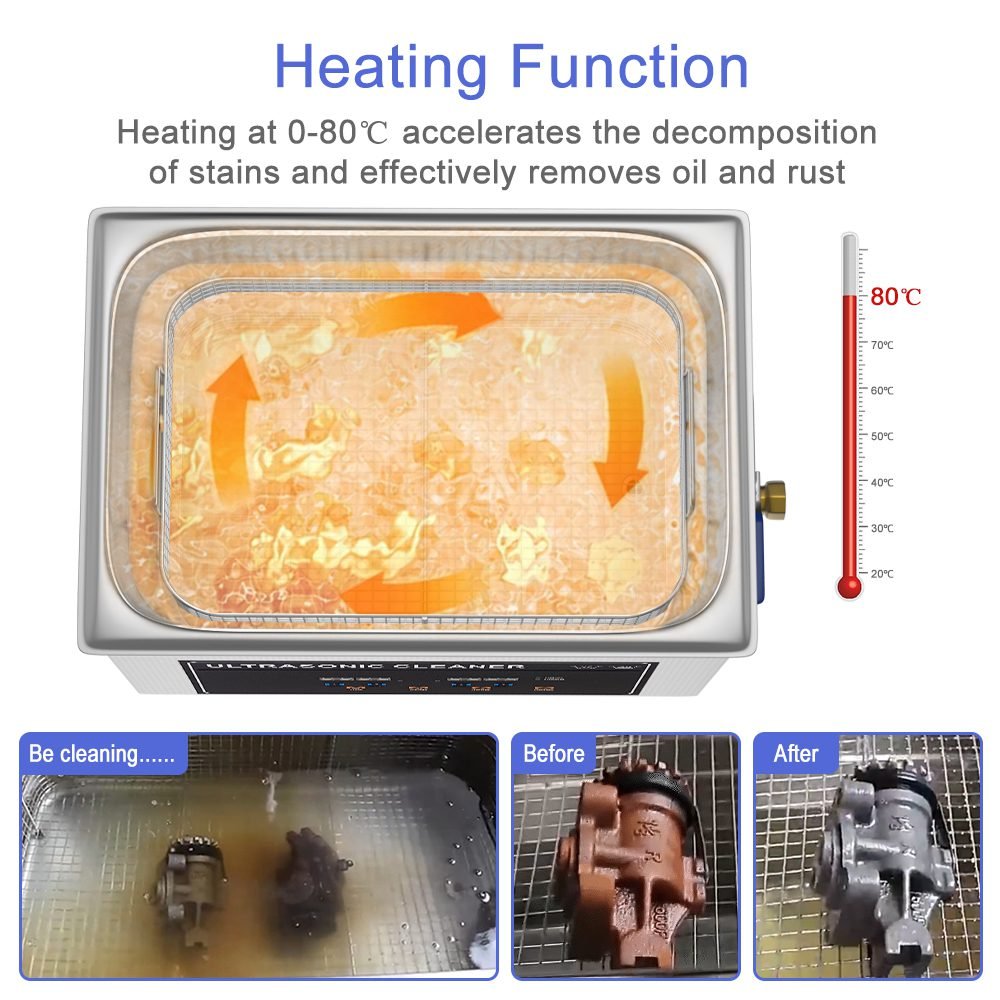

20-80°C

20-80°C

20-80°C

20-80°C

Control Type

Knob Mechanical Control

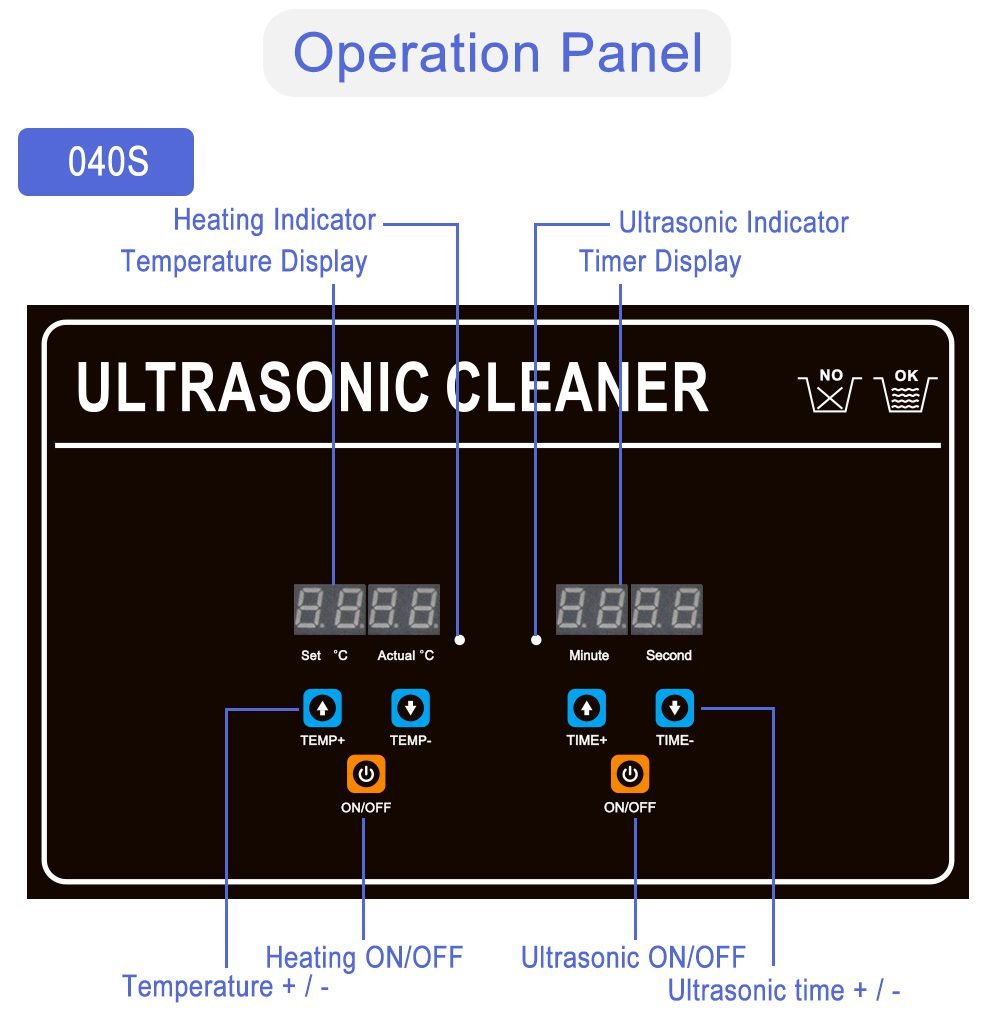

Digital Intelligent Control

Digital Intelligent Control

Digital Intelligent Control

Special Features

Basic Batch Cleaning

Digital Control + Degas

Dual-wave Cleaning + Degas

Stepless Power Adjustment

Drain System

Copper Core Fast Drain Valve

Copper Core Fast Drain Valve

Copper Core Fast Drain Valve

Copper Core Fast Drain Valve

Cooling System

Dual Fan Enhanced Cooling

Dual Fan Enhanced Cooling

Triple Fan Smart Cooling

Triple Fan Smart Cooling

Tank Size

11.81 x 9.45 x 5.9 inch

11.81 x 9.45 x 5.9 inch

11.81 x 9.45 x 5.9 inch

11.81 x 9.45 x 5.9 inch

Unit Size

12.8 x 10.43 x 11.02 inch

12.8 x 10.43 x 11.02 inch

12.8 x 10.43 x 11.02 inch

12.8 x 10.43 x 11.02 inch

Revolutionary Technical Innovations of Industrial Cleaner Automotive Engine Parts

Six-Transducer Matrix Layout (040-2 Series)

Industry-first Layout: 6×60W transducers arranged in matrix pattern, cleaning dead zones

Energy Density Increase: 50% higher energy density compared to traditional 4-transducer layouts

Intelligent Zone Control: Independent control of transducers in different zones enables

Redundant Backup Design: Single transducer failure doesn’t affect overall functionality, extremely high reliability

500W Super Heating System

Industrial-grade Heating Tubes: Special stainless steel heating tubes with 5000+ hours lifespan

Rapid Heating Capability: Heats 10L solution from room temperature to 80°C in 25 minutes

Zone Temperature Control: Front/rear zones Independent temperature control, adapts to different cleaning needs

Intelligent Energy-saving Mode: Automatically switches to keep warm mode after reaching set temperature

Triple Fan Intelligent Cooling System

Independent Air Duct Design: Separate heat dissipation for electronic control area, transducer area, heating area

Temperature-sensing Speed Control: Automatically adjusts fan speed based on internal temperature

Noise-optimized Design: Special fan blade design and vibration-damping installation reduces noise by 40%

Dust Filter System: Removable dust filter extends internal component lifespan

Professional Drainage & Maintenance System

Large Diameter Copper Core Valve: 38mm drain diameter, empties 10L capacity within 90 seconds

Quick-connect Interface: Standard quick-connect interface enables automatic drainage via piping

Maintenance Viewing Window: Side removable panel facilitates internal maintenance and inspection

Modular Design: All major functional modules can be independently disassembled and replaced

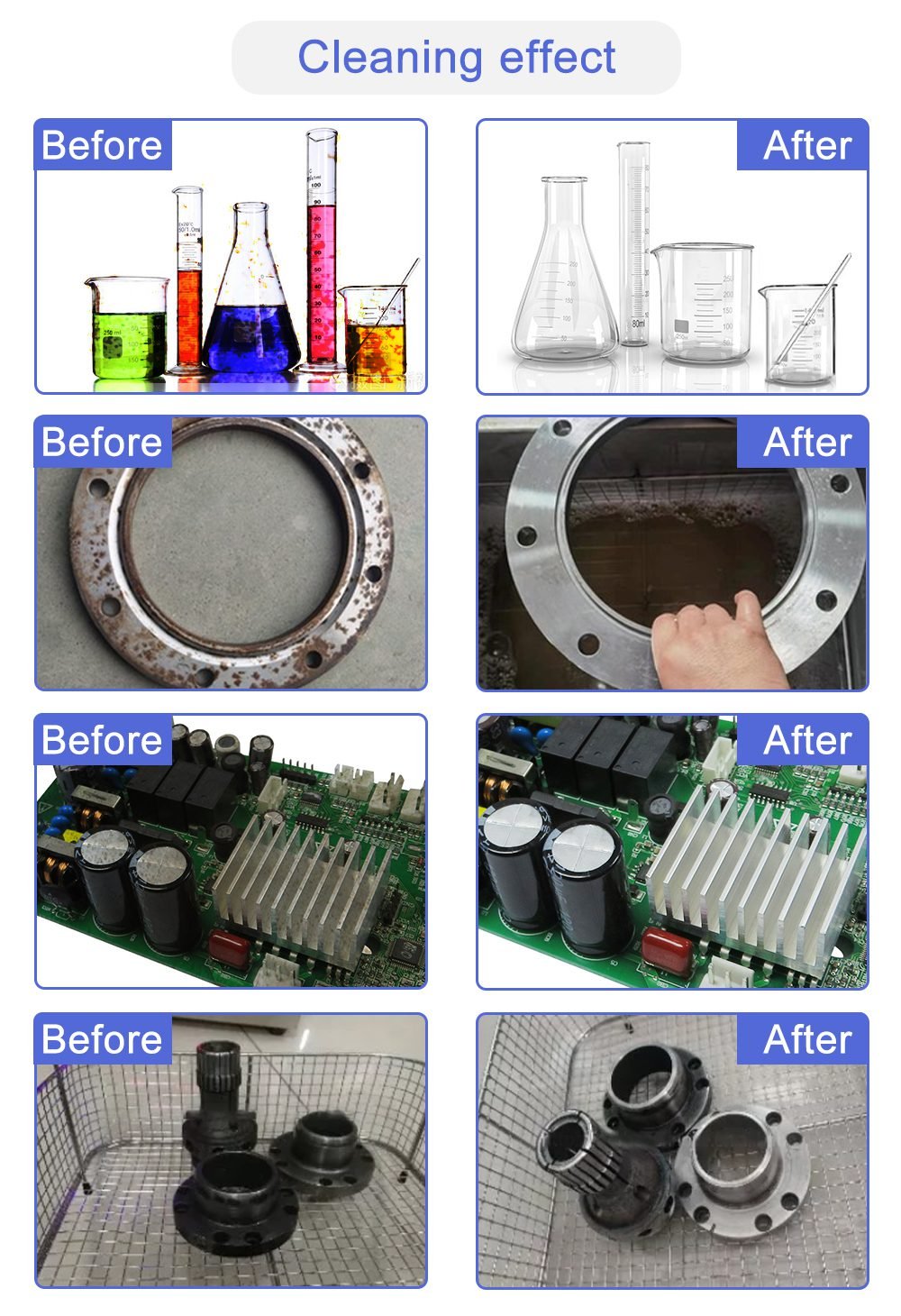

Industrial Application Scenarios Complete Analysis of Industrial System for Gun Saw Blade Hardware Metal Parts

Heavy Industry Manufacturing:

Automotive Engine Manufacturing: Batch cleaning of large parts like cylinder blocks, cylinder heads, crankshafts

Aerospace Manufacturing: Precision cleaning of aircraft engine components, landing gear parts

Rail Transit Equipment: Deep cleaning of train braking systems, transmission components

Heavy Machinery Manufacturing: Oil stain cleaning of construction machinery hydraulic parts, transmission gears

Medical Equipment Large-scale Processing:

Hospital Central Sterile Supply: Centralized batch processing of surgical instruments

Medical Device Manufacturers: Large-scale production cleaning of implants, surgical tools

Third-party Sterilization Centers: Outsourced cleaning services for multiple medical institutions

Dental Equipment Distributors: Batch refurbishment cleaning of dental handpieces and instruments

Electronics Manufacturing High-end Applications:

Semiconductor Manufacturing: Particle cleaning of wafer carriers, process chambers

Precision Circuit Boards: Batch cleaning of multilayer PCB boards, high-density connectors

Optical Component Manufacturing: Large-scale cleaning of camera modules, optical lenses

New Energy Batteries: Cleaning of battery electrode sheets, separator materials

Special Industry Professional Services:

Military Equipment Maintenance: Maintenance cleaning of weapon systems, optical sights

Petrochemical Equipment: Oil stain cleaning of valves, pipe fittings, exploration tools

Food & Beverage Industry: Food-grade deep cleaning of filling equipment, molds

Printing & Packaging Industry: Regular maintenance cleaning of large printing rollers, molds

Performance Data & Comparison Analysis of Cleaning Machine Automatic Washing Machine Benchtop

Performance Indicator

040 360W Version

Imported Similar Products

Domestic Ordinary Products

Competitive Advantage

Max Cleaning Capacity

10L/batch

8-10L/batch

6-8L/batch

25-67% Capacity leading

Power Density

36W/L

30-32W/L

20-25W/L

12-80% Intensity Increase

Heating Efficiency

25min(room temp→80°C)

30-35min

40-50min

17-50% Time Saving

Continuous Operation Time

12 hours

8-10 hours

4-6 hours

50-200% Stability Improvement

Daily Processing Capacity

200-300 pieces

150-200 pieces

80-120 pieces

33-250% Efficiency Increase

Energy Efficiency Ratio

0.92

0.85-0.88

0.75-0.80

5-23% Energy Efficiency Improvement

Investment Return Deep Analysis of Stainless Steel Digital Industrial Washer Electric Auto Parts Gas Carburetor Engine Washing

Initial Investment Details (040S-2 Example):

Equipment Purchase Cost: $1,200-1,500 (saves $800-1,200 compared to European brands)

Accessory Investment: Special cleaning basket $50, filter $30, piping $20

Installation Cost: No professional installation needed, saves $200-300

Training Cost: Free online training, saves on-site training fee $500

Annual Operating Cost Analysis:

Electricity Cost: Daily $2.5 (based on 8 hours, $0.15/kWh)

Cleaning Solution Cost: Daily $3.0 (specialized industrial cleaning solution)

Labor Cost: Daily $8.0 (0.5 person-day, $16/hour)

Maintenance Cost: Annual $120 (parts replacement and maintainance)

Total Annual Cost: Approx. $3,500 (based on 250 workdays)

Economic Benefits Output:

Direct Cleaning Service Revenue: Daily $80-120 (external cleaning services)

Internal Cost Savings: 60% cost saving compared to outsourced cleaning

Production Efficiency Improvement: 40% shorter cleaning time, 67% capacity increase

Quality Improvement Benefits: Product qualification rate improves from 95% to 99.5%

Total Annual Revenue: $15,000-25,000 (depending on application scenario)

Investment Recovery Period:

Fast Return Scenario: 3-6 months (high-intensity production environment)

Standard Return Scenario: 6-12 months (conventional industry application)

Long-term Value: Equipment lifespan 8-10 years, annual ROI 200-300%

Quality Assurance & Certification System of Ultrasonic Cleaning of Contaminants

International Authoritative Certifications:

ISO9001:2015 Quality Management System certification

ISO13485 Medical Device Quality Management System (medical versions)

Comprehensive European certifications: CE, RoHS, REACH

North American electrical safety certifications: UL/cUL (optional)

Canadian Standards Association certification: CSA (optional)

Manufacturing Quality Control:

Raw Material Traceability: All metal materials provided with material certificates and traceability certificate

Production Process Control: 48 quality control points with real-time data monitoring

Aging Test Standards: 120-hour continuous full-load aging test

Performance Verification Testing: Each unit completes 12 performance tests before leaving factory

Packaging & Shipping Standards: Export-grade wooden crate packaging, shockproof and moisture-proof treatment

Global Service System:

Installation Guidance Services: Multi-language video guidance + remote installation assistance

Operation Training System: Three-level training: basic operation + advanced application +troubleshooting

Technical Support Network: 24 global technical support centers, multi-language support

Parts Supply Guarantee: 5 global parts centers, 72-hour emergency parts supply

Regular Maintenance Plans: Provides annual, quarterly, monthly maintenance plan templates

Industry Customized Solutions of Ultrasonic Cleaning with Dual Frequency

Automotive Manufacturing Package:

Configuration: 2×040ST-2 + automotive special cleaning basket + degreasing cleaning solution

Functions: Engine parts cleaning line, supports mixed material parts cleaning

Services: Production line layout design + Cleaning process development + Employee certification training

Benefits: 300% cleaning efficiency improvement, 40% cleaning solution cost reduction

Medical Equipment Package:

Configuration: 3×040SD-2 + medical instrument racks + enzymatic cleaner + pure water system

Functions: Three-level surgical instrument classification cleaning, meets medical certification requirements

Services: Medical compliance consultation + Cleaning validation services + Regular biological monitoring

Benefits: 99.9% cleaning qualification rate, 50% extend instrument life

Electronics Manufacturing Package:

Configuration: 4×040S-2 + anti-static cleaning baskets + electronic-grade cleaning solutions

Functions: PCB board cleaning production line, particle control <100 particles/cm²

Services: Cleanliness testing + Process optimization + Employee cleanroom operation training

Benefits: 2% product yield improvement, 80% rework rate reduction

Third-party Cleaning Service Package:

Configuration: 1×each of 040/040S/040SD/040ST + multi-function accessory set

Functions: All-round cleaning service center, covers 95% customer needs

Services: Business model consultation + Marketing materials + Customer case library

Benefits: 50-100% annual service revenue growth, 95%+ customer satisfaction

OEM Cooperation Deep Package:

Product Customization: Complete design and manufacturing according to customer specifications, minimum order quantity 50 units

Brand Cooperation: Co-branding or customer independent brand, provides full range of brands solutions

Technology Licensing: Core cleaning technology licensing, supports customerlocalization production

Market Cooperation: Regional exclusive agent, shares technology and market resources

Technology Upgrades & Future Services of Ultrasonic Cleaning for Heavy Machinery

Hardware Upgrade Services:

Power Upgrade: 240W version field upgrade to 360W version (requires reserved interface)

Control Upgrade: Basic version upgraded to digital control or intelligent control version

Function Expansion: Adding filtration circulatory system, automatic liquid filling systems, etc.

Safety Upgrades: Installing emergency stop systems, remote monitoring systems, etc.

Software & Service Upgrades:

Intelligent Control Software: PC control software enablesremote monitoring and data management

Production Management Interface: MES/ERP system interfaces enable automatic production data collection

Preventive Maintenance System: Intelligent maintenance reminder system based on operational data

Cleaning Process Database: Industry-specific cleaning process parameter database

Sustainable Development Services:

Energy Consumption Optimization Consultation: Professional energy analysis, provides energy saving renovation solutions

Environmental Compliance Services: Cleaning solution environmentally friendly treatment consultation and compliance certification

Equipment Recycling Program: Old equipment recycling and trade-in services

Carbon Footprint Assessment: Full life cycle carbon footprint assessment and emission reduction recommendations

Send Inquiry

Hot Tags

#10LUltrasonicCleaner #360WSuperPower #IndustrialBatchCleaning #SixTransducerCleaner

#MedicalEquipmentBatchProcessing #IndustrialGradeCleaning #ProfessionalManufacturer #OEMDeepCustomization

#040UltrasonicCleaner #SuperHeatingSystem #IntelligentCoolingTechnology #CopperCoreDrainValve

#AutoPartsBatchCleaning #AerospaceCleaning #SemiconductorManufacturingCleaning #HeavyIndustryApplications