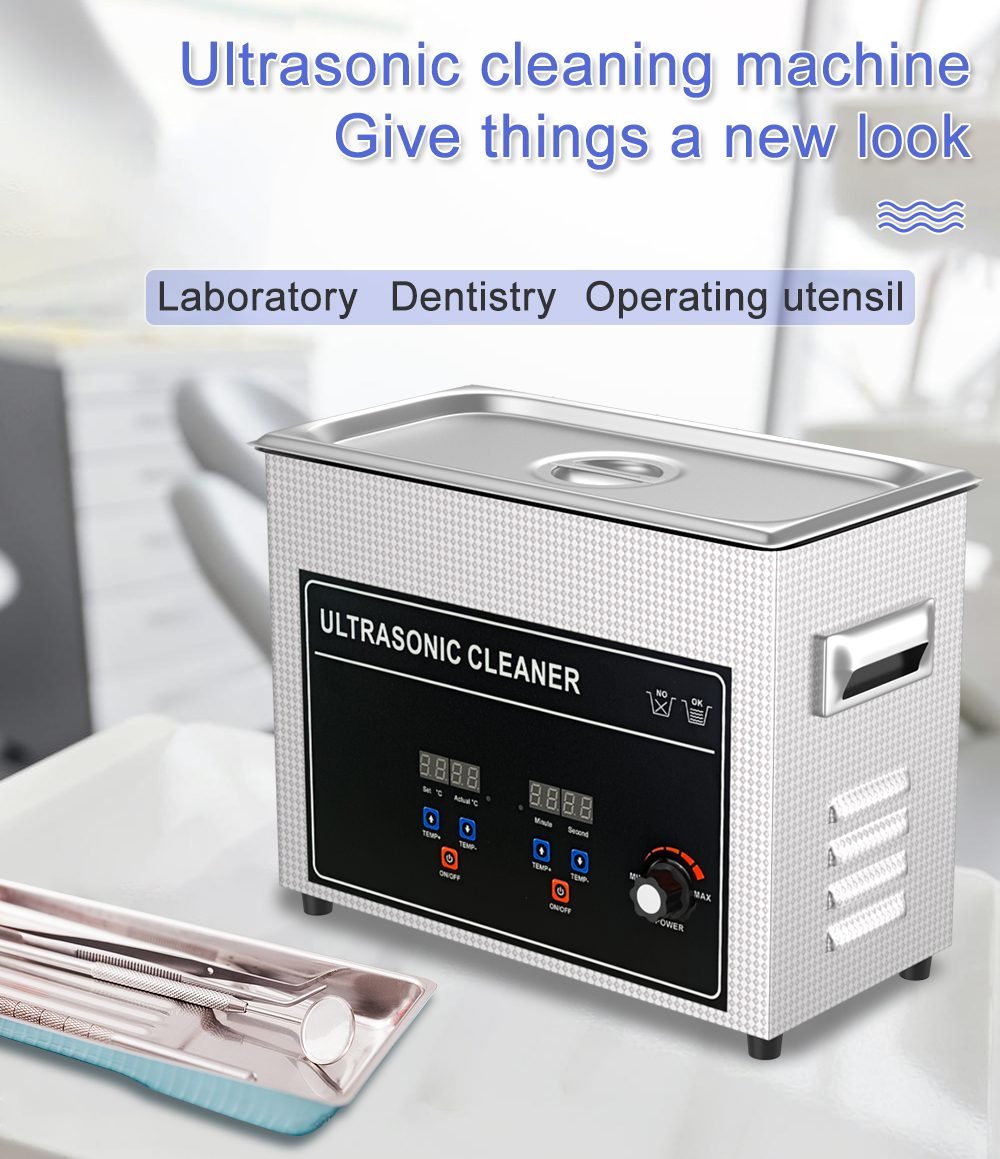

030 Series 4.5L Industrial Ultrasonic Cleaner | 300W Heating Power | Laboratory Medical Equipment Cleaning | Professional Grade Cleaning Solutions

Professional manufacturer CleaningSonic offers 030 series 4.5L extra large capacity ultrasonic cleaners with 300W powerful heating system, 180W ultrasonic power, 40KHz industrial transducers. Designed for laboratory, hospital, industrial batch cleaning. Global plug customization & OEM/ODM services available.

030 Series: Industrial High-Power Ultrasonic Cleaners - Batch Cleaning Professional Solutions

Product Description of Ultrasonic Cleaner

The CleaningSonic 030 Series Industrial Ultrasonic Cleaners are designed for large-scale, high-intensity professional cleaning requirements. Featuring a 4.5L extra large capacity 304 stainless steel tank, 3 industrial-grade transducers (total 180W power), and a 300W powerful heating system, these units provide exceptional batch cleaning capabilities. The intelligent temperature control system (precise adjustment 20-80°C) and multi-mode cleaning functions meet various professional cleaning needs from laboratory ware to medical surgical instruments.

This series offers multiple control method options including knob control, digital control, and adjustable power models, equipped with professional cooling systems and safety protection devices. As a professional manufacturer, we provide comprehensive OEM customization services for global distributors, supporting multiple international plug standards.

This series offers 8 professional configurations including standard, adjustable power, and dual-wave cleaning models to meet different precision cleaning requirements. Global plug customization service ensures plug-and-play operation worldwide. As a professional manufacturer, we provide comprehensive OEM/ODM customization solutions for global distributors.

Product Specifications of Digital Ultrasonic Cleaning Machine with Heater and Timer

Model

030

030S

030SD

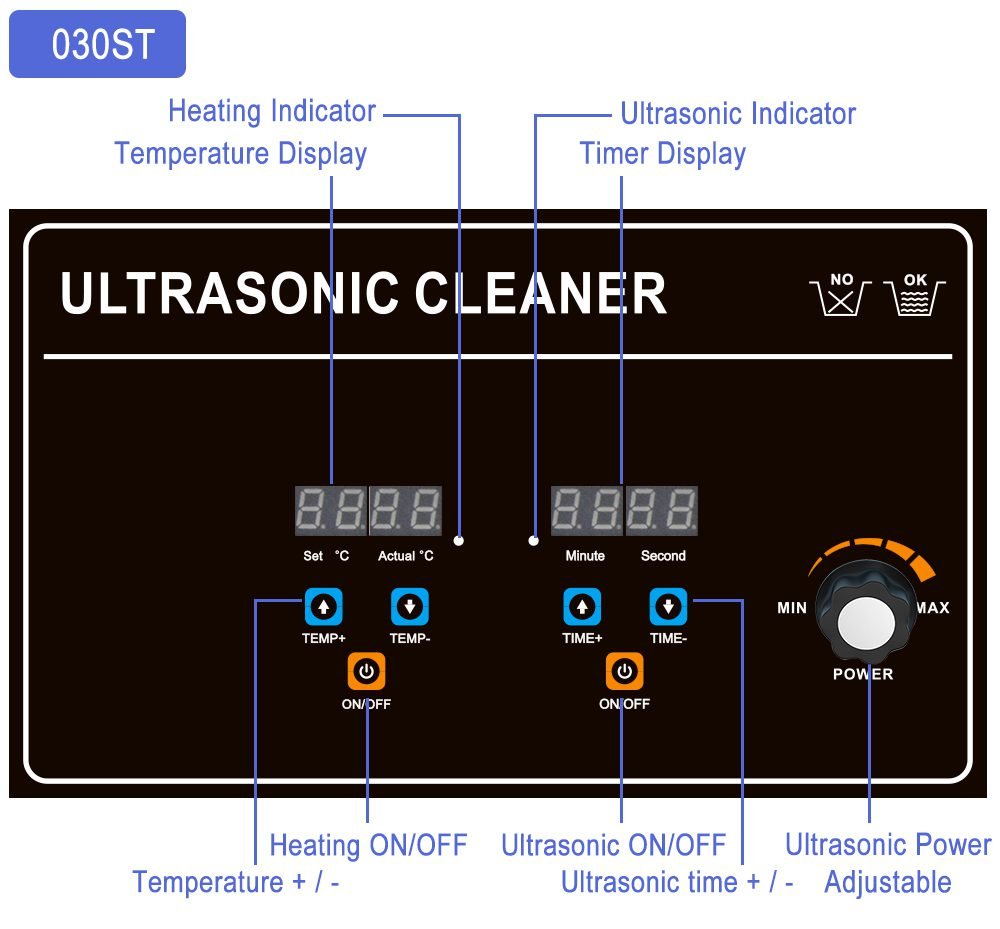

030ST

Capacity

4.5L

4.5L

4.5L

4.5L

Ultrasonic Power

180W

180W

90W/180W Dual Power

0-180W Adjustable

Transducer Qty

3

3

3

3

Single Transducer Power

60W

60W

60W

60W

Heating Power

300W

300W

300W

300W

Frequency

40KHz

40KHz

40KHz

40KHz

Temp. Range

20-80°C

20-80°C

20-80°C

20-80°C

Timer Range

1-30 min

1-30 min

1-30 min

1-30 min

Control Type

Knob Control

Digital Control

Digital Control

Digital Control

Special Features

Basic Cleaning

Digital Control + Degas

Dual-wave Cleaning + Degas

Stepless Power Adjustment

Display

Basic Indicators

Digital Display

Digital Display

Digital Display

Cooling System

Standard Air Cooling

Standard Air Cooling

Enhanced Air Cooling

Enhanced Air Cooling

Tank Size

11.81×5.9×3.94″

11.81×5.9×3.94″

11.81×5.9×3.94″

11.81×5.9×3.94″

Unit Size

12.8×7.09×8.86″

12.8×7.09×8.86″

12.8×7.09×8.86″

12.8×7.09×8.86″

Core Features & Functions of Stainless Steel Ultrasonic Cleaner Machine

Extra Large Capacity Industrial Design

4.5L Professional Capacity: Can clean multiple large items or batches of small items simultaneously

304 Stainless Steel Thickened Tank: 2.0mm thickness, robust and durable, suitable for long-term high-intensity use

Three-Transducer Array Layout: Three 60W industrial transducers evenly distributed at bottom ensure uniform cleaning

Powerful Heating & Temperature Control System

300W High-Power Heating: Fast heating, maximum temperature 80°C, suitable for high-temperature cleaning needs

Intelligent PID Temperature Control: Temperature control accuracy ±1°C, ensures stable cleaning process

Dual Temperature Display: Shows both set temperature and actual temperature simultaneously

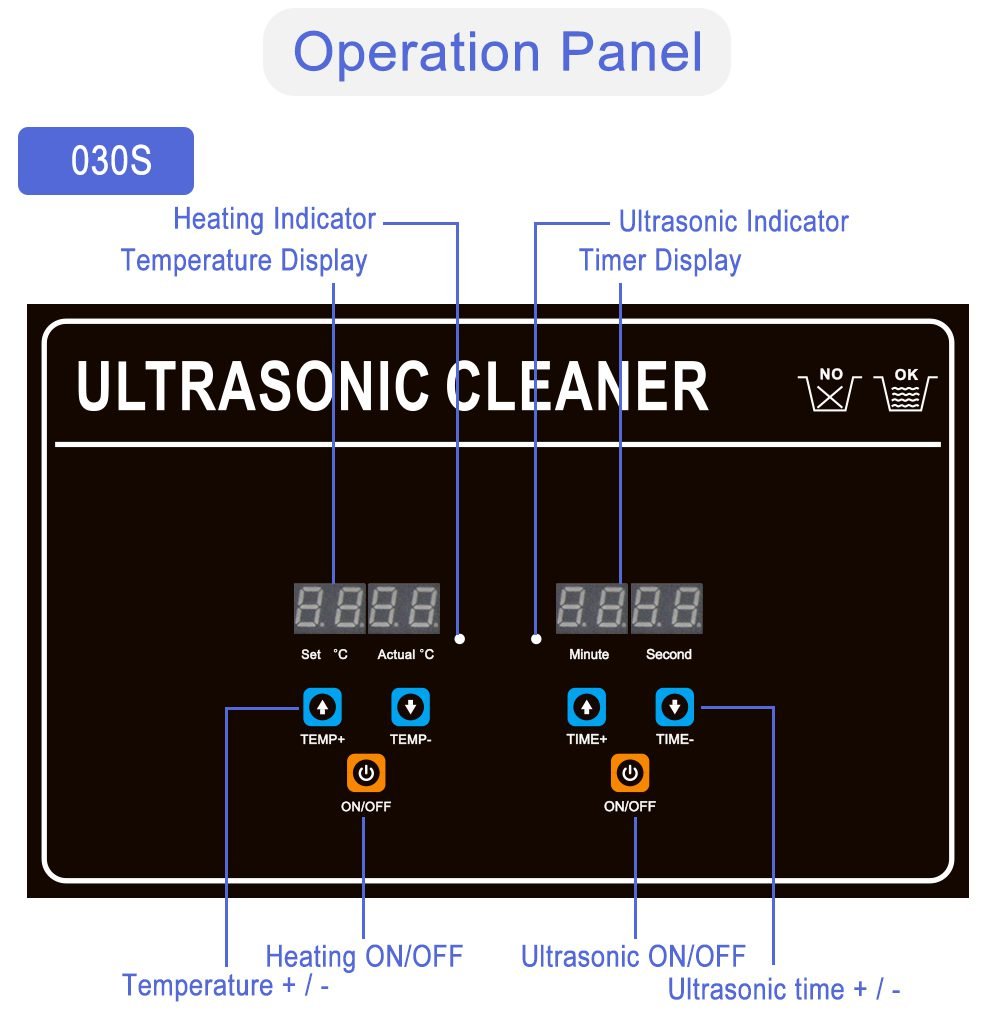

Professional Operation & Control System

Multi-function Operation Panel: Independent temperature and time adjustment, independent heating and ultrasonic control

Status Indicators: Clear display of heating, ultrasonic, and timer status

Professional Cooling System: Built-in fan cooling ensures stability during prolonged continuous operation

Safety & Ergonomic Design

Dual Safety Switch Protection: Prevents accidental operation, ensures safe use

Insulated Heat-proof Handle: Ergonomic design for safe and convenient handling

Non-slip Vibration-damping Feet: Four-corner non-slip design effectively reduces operational vibration

Multi-angle Viewing Window: 360° monitoring of cleaning process

Global Power Adaptation: Supports Australian, British, American, European and other plug standards

Technical Advantages Explained of Ultrasonic Parts Cleaner for Retainer Glasses Auto Tool Machine Part

Three-Transducer Array Technology

Uniform Energy Distribution: Three transducers arranged in triangular layout eliminate cleaning dead zones

Synergistic Effect: Multiple transducers work together to produce stronger cavitation effect

Redundant Design: Single transducer failure doesn’t affect basic use, higher reliability

300W High-Power Heating System

Fast Heating: Heats from room temperature to 80°C in only 15-20 minutes

Constant Temperature Maintenance: Intelligent PID control ensures temperature stability, suitable for processes requiring constant temperature cleaning

Energy-saving Design: Automatically reduces heating power after reaching set temperature, saves energy

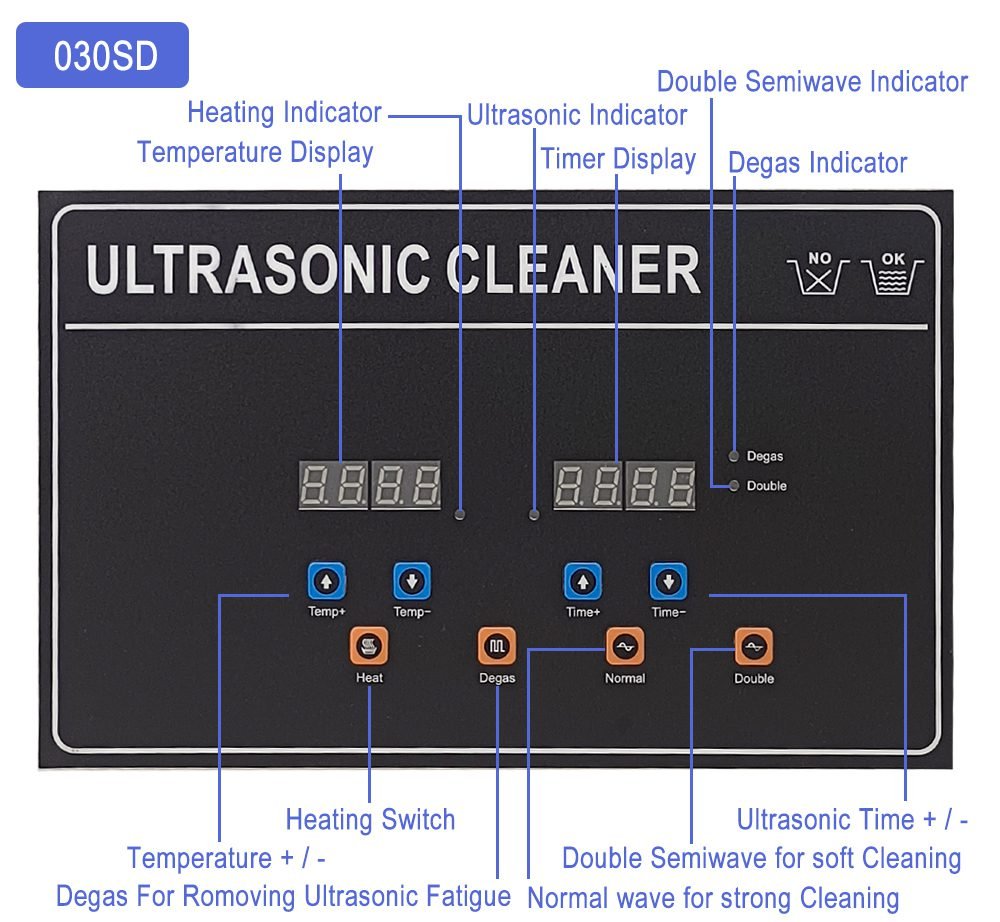

Intelligent Cleaning Modes

Standard Cleaning Mode (030/030S): Suitable for most conventional cleaning needs

Dual-wave Cleaning Mode (030SD): Switch between intensive and gentle waves, versatile machine

Adjustable Power Mode (030ST): 0-180W stepless adjustment, maximum adaptability

Product Series Detailed Explanation of Ultrasound Cleaning Machine with Heater and Timer

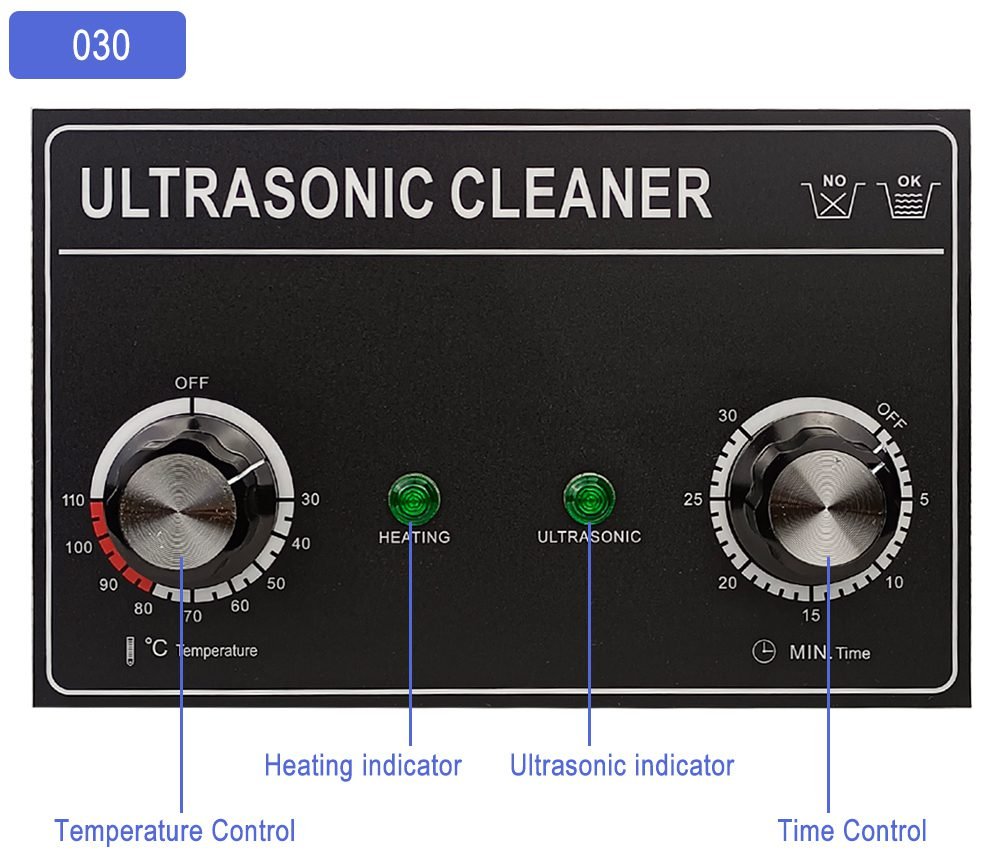

030 Series (Basic Knob Control)

Suitable For: Industrial batch cleaning requiring operational simplicity

Core Advantages: Intuitive operation, simple maintenance, cost-effective

Typical Applications: Auto repair shop batch parts cleaning, machining workshop tool cleaning

030S Series (Digital Standard Control)

Suitable For: Laboratories and medical facilities requiring precise parameter control

Core Advantages: Digital display, precise parameters, comprehensive functions

Typical Applications: Hospital sterilization supply centers, research laboratory ware cleaning

030SD Series (Dual-wave Professional Cleaning)

Suitable For: Professional venues handling items of different materials and contamination levels

Core Advantages: Dual-wave technology, wide application range, excellent cleaning results

Typical Applications: Electronics manufacturing plants, precision instrument repair centers, dental instrument cleaning

030ST Series (Adjustable Power Premium Model)

Suitable For: Top-tier applications with refined cleaning process requirements

Core Advantages: Stepless power adjustment, adapts to various special cleaning needs

Typical Applications: High-end jewelry processing, optical instrument manufacturing, precision mold cleaning

Application Scenarios Deep Analysis of Stainless Steel Ultrasonic Washing Machine

Medical & Healthcare Batch Cleaning:

Hospital Central Sterile Supply: Pre-cleaning and sterilization of large batches of surgical instruments

Dental Chain Institutions: Centralized cleaning of multi-clinic instruments

Testing Centers: Standardized cleaning of large quantities of testing ware

Pharmaceutical Companies: Cleaning validation of production equipment and containers

Laboratory & Research Batch Processing:

University Teaching Labs: Centralized cleaning management of student experiment equipment

Research Institutes: Batch sample processing for large research projects

Quality Inspection Agencies: Standardized pre-treatment of large quantities of testing samples

Environmental Monitoring Stations: Batch cleaning and maintenance of sampling equipment

Industrial Manufacturing Batch Cleaning:

Auto Parts Factories: Batch cleaning of engine parts, transmission components

Aerospace: Batch cleaning of precision components

Mold Manufacturing: Cleaning and maintenance of large molds and processing tools

Electronics Manufacturing: Batch cleaning of PCB boards, connectors

Professional Service Institutions:

Large Jewelry Processing Factories: Batch cleaning of precious metals and gemstones

Watch Manufacturing Companies: Large batch cleaning of watch components

Premium Eyewear Chains: Centralized cleaning of frames and lenses

Cultural Relic Restoration Agencies: Professional cleaning of large artifacts and artworks

Performance Comparison Table of Professional Ultrasound Parts Cleaning Machine for Lab Tool Glasses Auto Part

Performance Indicator

030 Series

Ordinary 2-3L Cleaners

Advantage Comparison

Cleaning Capacity

4.5L

2-3L

50-125% Capacity Increase

Heating Power

300W

150W

100% Faster Heating

Ultrasonic Power

180W

60-120W

50-200% Cleaning Strength Increase

Continuous Operation Time

8 hours

4 hours

100% Stability Improvement

Temperature Control Accuracy

±1°C

±3-5°C

3-5 Times Precision Improvement

Batch Processing Capability

20-30 items/batch

10-15 items/batch

100% Efficiency Increase

Quality Assurance System of ECO Energy-Saving Ultrasonic Cleaning Machine

Manufacturing Standards:

ISO9001:2015 Quality Management System certification

ISO13485 Medical Device Quality Management System (optional)

International certifications including CE, RoHS, REACH

Strict factory inspection standards

Key Component Quality Control:

Transducers: Imported piezoelectric ceramics, 100% performance testing

Stainless Steel Tank: Food-grade 304 material, thickness testing, weld inspection

Control System: Independently developed, 72-hour continuous aging test

Heating System: Multiple safety protections, automatic power-off on overheating

After-sales Service Policy:

Warranty Period: 18 months for whole unit, 36 months extended warranty for transducers

Response Time: Technical consultation response within 2 hours, fault diagnosiswithin 24 hours

Parts Supply: 10-year guaranteed supply of key components

Remote Support: Modern service methods including video guidance, remote diagnostics

OEM Cooperation Packages:

Basic Customization: LOGO printing, color customization, packaging design

Deep Customization: Function adjustment, specification modification, software customization

Joint Development: Co-develop new models based on market needs

Send Inquiry

Hot Tags

#4.5LUltrasonicCleaner #IndustrialGradeCleaningEquipment #BatchCleaner #HighPowerUltrasonicCleaner

#MedicalEquipmentCleaner #LaboratoryBatchCleaning #300WHeatedCleaner #ProfessionalCleaningEquipment

#030UltrasonicCleaner #HospitalSterilizationEquipment #IndustrialPartsBatchCleaning #OEMCustomCleaner

#ThreeTransducerCleaner #LargeCapacityCleaningEquipment #SmartTemperatureControlCleaner #GlobalVoltageCleaningEquipment