020 Series 3.2L Large Capacity Ultrasonic Cleaner | Laboratory Medical Cleaning Equipment | Adjustable Power 0-180W | CleaningSonic Manufacturer

Professional manufacturer CleaningSonic offers 020 series 3.2L large capacity ultrasonic cleaners with dual/semi-wave technology, adjustable power 0-180W, temperature 20-80°C. Suitable for laboratories, medical equipment, industrial parts cleaning. Global plug customization, 8 models available, OEM services supported.

020 Series: Large Capacity Professional Ultrasonic Cleaners - Laboratory & Industrial Grade Cleaning Solutions

Product Description of Ultrasonic Cleaning for Filters

The CleaningSonic 020 Series Large Capacity Ultrasonic Cleaners are designed specifically for laboratory, medical, and industrial applications. Featuring a 3.2L 304 stainless steel tank coupled with 2-3 industrial-grade transducers providing 120W/180W powerful cleaning performance. Exclusive dual/semi-wave cleaning technology enables seamless switching between intensive and gentle cleaning modes. Intelligent digital control system supports stepless power adjustment from 0-180W and precise temperature control from 20-80°C.

This series offers 8 professional configurations including standard, adjustable power, and dual-wave cleaning models to meet different precision cleaning requirements. Global plug customization service ensures plug-and-play operation worldwide. As a professional manufacturer, we provide comprehensive OEM/ODM customization solutions for global distributors.

Product Specifications of Ultrasonic Cleaning for Laboratory Equipment

Model

020

020-1

020S

020S-1

020SD

020SD-1

020ST

020ST-1

Capacity

3.2L

3.2L

3.2L

3.2L

3.2L

3.2L

3.2L

3.2L

Ultrasonic Power

120W

180W

120W

180W

60W/120W

90W/180W

0-120W Adjustable

0-180W Adjustable

Transducer Qty

2

3

2

3

2

3

2

3

Heating Power

150W

150W

150W

150W

150W

150W

150W

150W

Frequency

40KHz

40KHz

40KHz

40KHz

40KHz

40KHz

40KHz

40KHz

Temp. Range

20-80°C

20-80°C

20-80°C

20-80°C

20-80°C

20-80°C

20-80°C

20-80°C

Timer Range

1-30 min

1-30 min

1-30 min

1-30 min

1-30 min

1-30 min

1-30 min

1-30 min

Control Type

Knob Control

Knob Control

Digital Control

Digital Control

Digital Control

Digital Control

Digital Control

Digital Control

Special Features

Basic Cleaning

Basic Cleaning

Digital Control

Digital Control

Dual-wave Cleaning

Dual-wave Cleaning

Stepless Power Adjust

Stepless Power Adjust

Tank Size

9.45×5.31×3.94″

9.45×5.31×3.94″

9.45×5.31×3.94″

9.45×5.31×3.94″

9.45×5.31×3.94″

9.45×5.31×3.94″

9.45×5.31×3.94″

9.45×5.31×3.94″

Unit Size

10.43×6.5×8.66″

10.43×6.5×8.66″

10.43×6.5×8.66″

10.43×6.5×8.66″

10.43×6.5×8.66″

10.43×6.5×8.66″

10.43×6.5×8.66″

10.43×6.5×8.66″

Core Features & Functions of Ultrasonic Cleaning for Automotive Body Parts

Extra Large Capacity Professional Design

3.2L Industrial Capacity: Meets laboratory batch cleaning requirements

304 Stainless Steel Tank: Corrosion-resistant, easy to clean, suitable for various chemical cleaning solutions

Industrial Transducer Configuration: 2-3 pcs of 40KHz transducers, 40,000 high-frequency vibrations per second

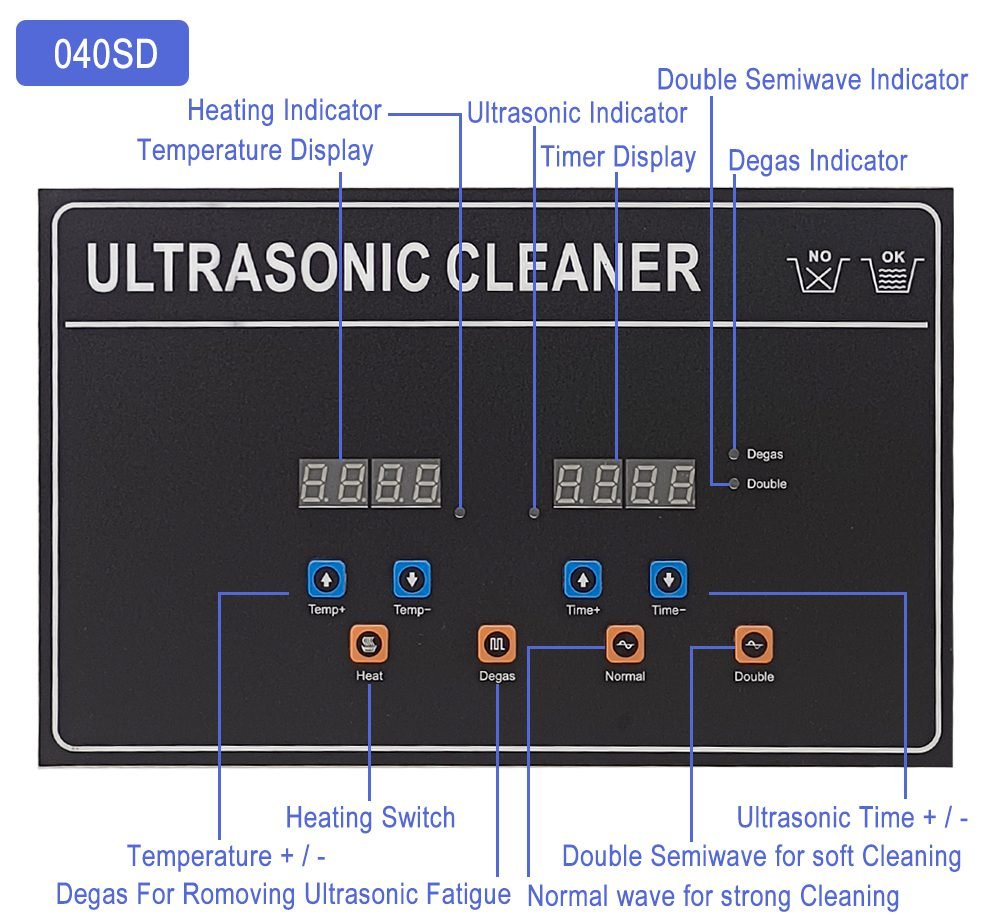

Advanced Cleaning Technology

Dual/Semi-wave Cleaning Technology (020SD series): Intensive wave for stubborn stains, gentle wave for delicate items

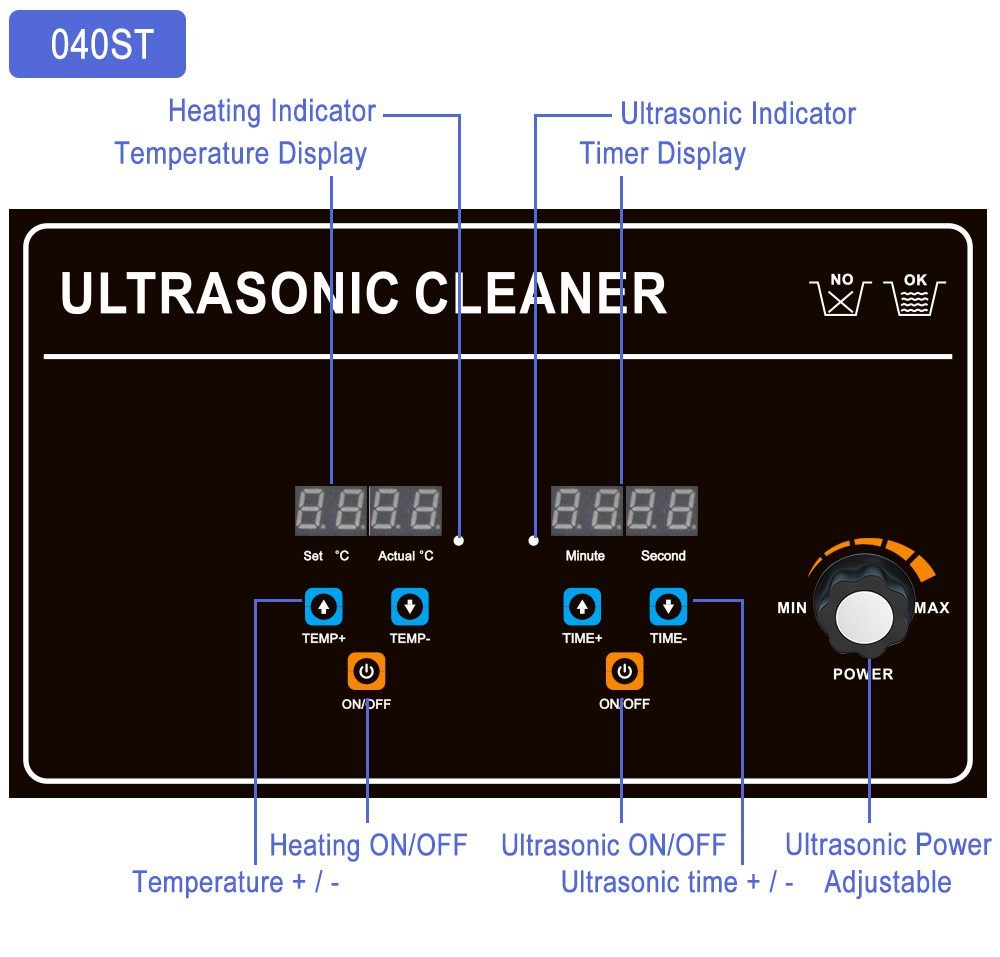

Stepless Power Adjustment (020ST series): Continuously adjustable from 0-180W, adapts to different cleaning requirements

Intelligent Degas Function: Optimizes cleaning solution penetration, improves efficiency by 30%

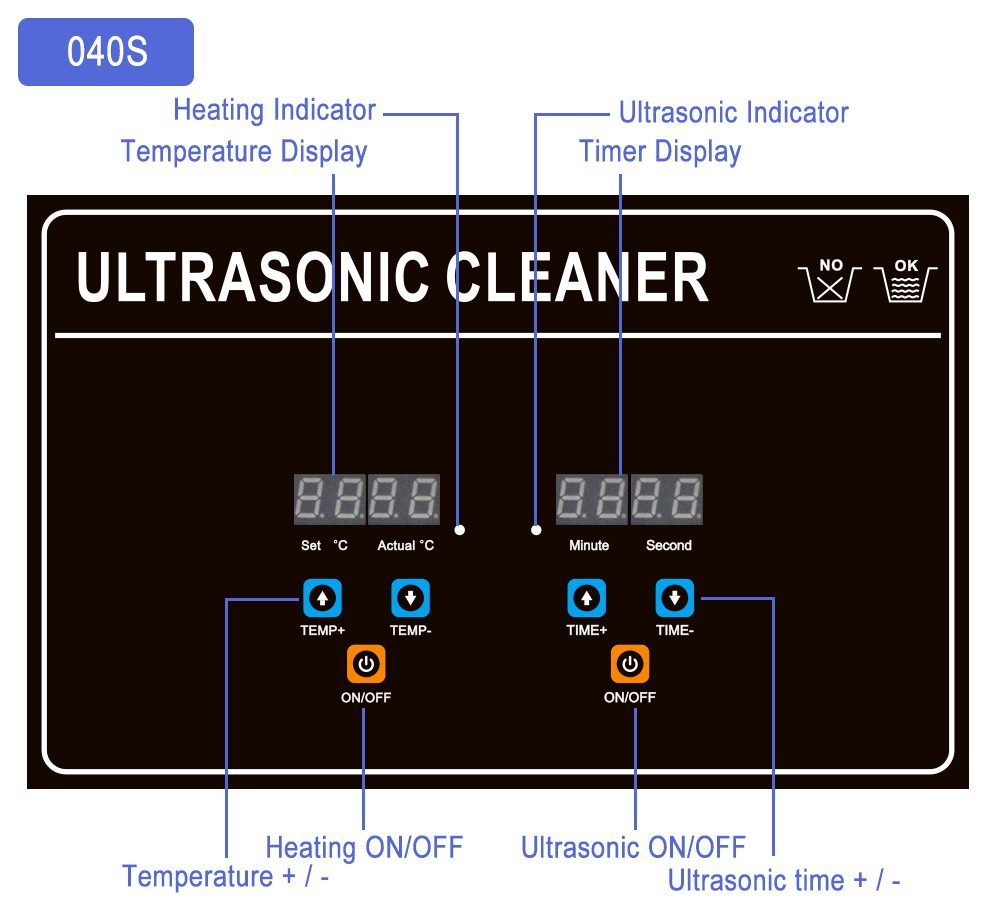

Professional Operation Panel

Digital Temperature Display: Dual display of set temperature and actual temperature

Precise Timer Control: Adjustable 1-30 minutes, meets different item cleaning durations

Independent Control Switches: Separate heating and ultrasonic controls for flexible operation

Function Indicators: Clear status indication for heating, ultrasonic, and timer control

Safety & Ergonomic Design

Dual Safety Switches: Prevent accidental operation, ensure safe use

Insulated Handle: Heat-proof design for safe and convenient handling

Non-slip Feet: Four-corner non-slip design reduces vibration noise

Multi-angle Viewing Window: 360° clear monitoring of cleaning process

Global Plug Customization: Supports Australian, British, American, European and other plug standards

Technical Advantages Explained of Ultrasonic Cleaning with Adjustable Power

Dual/Semi-wave Cleaning Technology

Intensive Wave Mode: Standard ultrasonic wave, suitable for metal parts, tools with stubborn stains

Gentle Wave Mode: Semi-wave output, suitable for delicate electronic components, optical lenses

Intelligent Switching: One-touch switching between cleaning modes based on item material

Stepless Power Adjustment Technology

Continuous Power Adjustment: Stepless adjustment from 0 to maximum power

Enhanced Adaptability: Precisely matches different item cleaning requirements

Energy Saving: Reduces energy consumption by 50% in low-power mode

Intelligent Temperature Control System

PID Precise Control: Temperature fluctuation controlled within ±1°C

Dual Protection: Automatic overheat protection prevents temperature runaway

Fast Heating: 150W heating power ensures quick temperature rise

Product Series Detailed Explanation of Ultrasonic Cleaning for Plastics

020/020-1 Series (Basic Knob Control)

Suitable For: Industrial cleaning where control precision is not critical

Core Advantages: Simple operation, cost-effective, easy maintenance

Recommended Users: Auto repair shops, machining workshops

020S/020S-1 Series (Digital Standard Control)

Suitable For: Laboratories, medical equipment cleaning requiring precise control

Core Advantages: Digital display, precise operation, comprehensive functions

Recommended Users: Research laboratories, hospital sterilization centers

020SD/020SD-1 Series (Dual-wave Cleaning)

Suitable For: Professional venues needing to handle different material items

Core Advantages: Dual-wave switching, versatile machine, wide application range

Recommended Users: Electronics manufacturers, precision instrument repair centers

020ST/020ST-1 Series (Adjustable Power)

Suitable For: Professional applications requiring fine-tuned cleaning intensity

Core Advantages: Stepless power adjustment, maximum adaptability

Recommended Users: Jewelry processing factories, optical instrument manufacturers

Application Scenarios Deep Analysis of Ultrasonic Cleaning for Polished Surfaces

Laboratory & Research Applications:

Chemistry Labs: Cleaning labware, sampling tools

Biology Labs: Cleaning petri dishes, pipettes

Physics Labs: Cleaning optical components, precision measuring tools

Teaching Labs: Batch cleaning of student experiment equipment

Medical & Healthcare Field:

Hospital CSSD: Pre-cleaning of surgical instruments

Dental Clinics: Dental instrument cleaning and disinfection

Testing Departments: Medical testing equipment cleaning

Rehabilitation Centers: Daily cleaning of physiotherapy equipment

Industrial Manufacturing Applications:

Electronics Manufacturing: PCB boards, chips, connector cleaning

Precision Machinery: Bearings, gears, mold cleaning

Automotive Manufacturing: Engine parts, injector cleaning

Aerospace: Precision component cleaning

Professional Service Institutions:

Jewelry Processing: Deep cleaning of precious metals, gemstones

Watch Repair: Professional cleaning of watch movements, cases

Optical Instruments: Lens, prism, filter cleaning

Cultural Relic Restoration: Professional cleaning of antiques, artworks

Global Market Adaptability of Ultrasonic Cleaning for Printed Circuit Boards (PCBs)

Power Adaptability:

Voltage Range: AC 100-240V, 50/60Hz globally compatible

Plug Customization: Supports Australian, British, American, European and other standards

Safety Certifications: Complete international certifications including CE, RoHS

Environmental Adaptability:

Operating Temperature: Stable operation at 5-40°C ambient temperature

Humidity Range: Normal operation at ≤80% relative humidity

Altitude: Usable in areas below 2000 meters elevation

Service Support Network:

Global Agents: Service networks in Europe, North America, Southeast Asia

Multi-language Support: Manuals in English, Chinese, German, French and more

Online Technical Support: 24-hour online technical consultation

Investment Return & Value Analysis of Ultrasonic Cleaning for Automotive Parts

Initial Investment Analysis:

Equipment Cost: 40-60% price advantage compared to imported brands

Installation Cost: Plug-and-play, no professional installation needed

Training Cost: Simple operation, minimal training time required

Operating Cost Advantages:

Energy Cost: Intelligent power adjustment reduces energy consumption by 30%

Maintenance Cost: Modular design ensures simple, low-cost maintenance

Consumable Cost: Optimized cleaning solution usage saves 20%

Value Creation Capability:

Efficiency Improvement: Batch cleaning capability improves efficiency 5-10 times

Quality Assurance: Standardized cleaning process ensures stable, controllable quality

Business Expansion: Can undertake external cleaning services, creating new revenue

Brand Enhancement: Professional equipment usage improves institutional image

Quality Assurance & Certifications of Custom Ultrasonic Cleaner

Manufacturing Standard Certifications:

ISO9001:2015 Quality Management System certification

ISO13485 Medical Device Quality Management System (optional)

EU certifications including CE, RoHS, REACH

North American certifications including UL, FCC (optional)

Quality Inspection Process:

Raw Material Inspection: 304 stainless steel material test reports

Production Process Control: Quality checkpoints at each production stage

Finished Product Full Inspection: 100% function testing, 72-hour aging test

Shipment Inspection: Comprehensive appearance, function, packaging check

After-sales Service Commitment:

Warranty Policy: 12 months for whole unit, 24 months for transducers

Response Time: Technical consultation response within 24 hours

Parts Supply: Key parts guaranteed supply for 10 years

Upgrade Service: Free software function upgrade service

Product Selection Decision Tree

Step 1: Determine Primary Use

Industrial parts cleaning → Consider 020 or 020-1 series

Laboratory ware cleaning → Consider 020S or 020S-1 series

Precision electronic component cleaning → Prioritize 020SD or 020SD-1 series

Mixed material cleaning → First choice 020ST or 020ST-1 series

Step 2: Determine Cleaning Intensity Requirements

Regular cleaning, light stains → 120W power models sufficient

Stubborn stains, need powerful cleaning → Choose 180W high-power models

Both delicate items and stubborn stains → Choose dual-wave cleaning models

Variable cleaning requirements → Choose adjustable power models

Step 3: Consider Control Precision Needs

Operators with basic technical skills → Knob control models

Need precise parameter control → Digital control models

Need to record cleaning parameters → Digital control models with memory function

Step 4: Budget & Investment Plan

Limited budget, basic needs → 020 basic models

Medium budget, need good functionality → 020S series

Ample budget,Pursue the best performance → 020ST-1 premium models

Send Inquiry

Hot Tags

#LargeCapacityUltrasonicCleaner #3.2LCleaner #LaboratoryCleaningEquipment #MedicalUltrasonicCleaner

#AdjustablePowerCleaner #DualWaveUltrasonic #IndustrialGradeCleaningEquipment #OEMCustomCleaner

#020UltrasonicCleaner #LaboratoryInstrumentCleaning #MedicalEquipmentCleaning #ElectronicComponentCleaner

#JewelryProcessingEquipment #PrecisionPartsCleaning #GlobalVoltageCleaner #SmartTemperatureControlCleaning