010 Series 2L Industrial Ultrasonic Cleaner | Professional Jewelry Tool Cleaning | Heating Temperature Control | CleaningSonic Manufacturer

CleaningSonic manufactures 010 series 2L industrial ultrasonic cleaners with 304 stainless steel tank, industrial transducers, intelligent temperature control. 60W/120W power options, suitable for jewelry manufacturing, tool repair, industrial parts cleaning. OEM customization & professional solutions for global distributors.

010 Series: Industrial-Grade Ultrasonic Cleaners - Professional Manufacturing Cleaning Solutions

Product Description of Precision Ultrasonic Cleaning

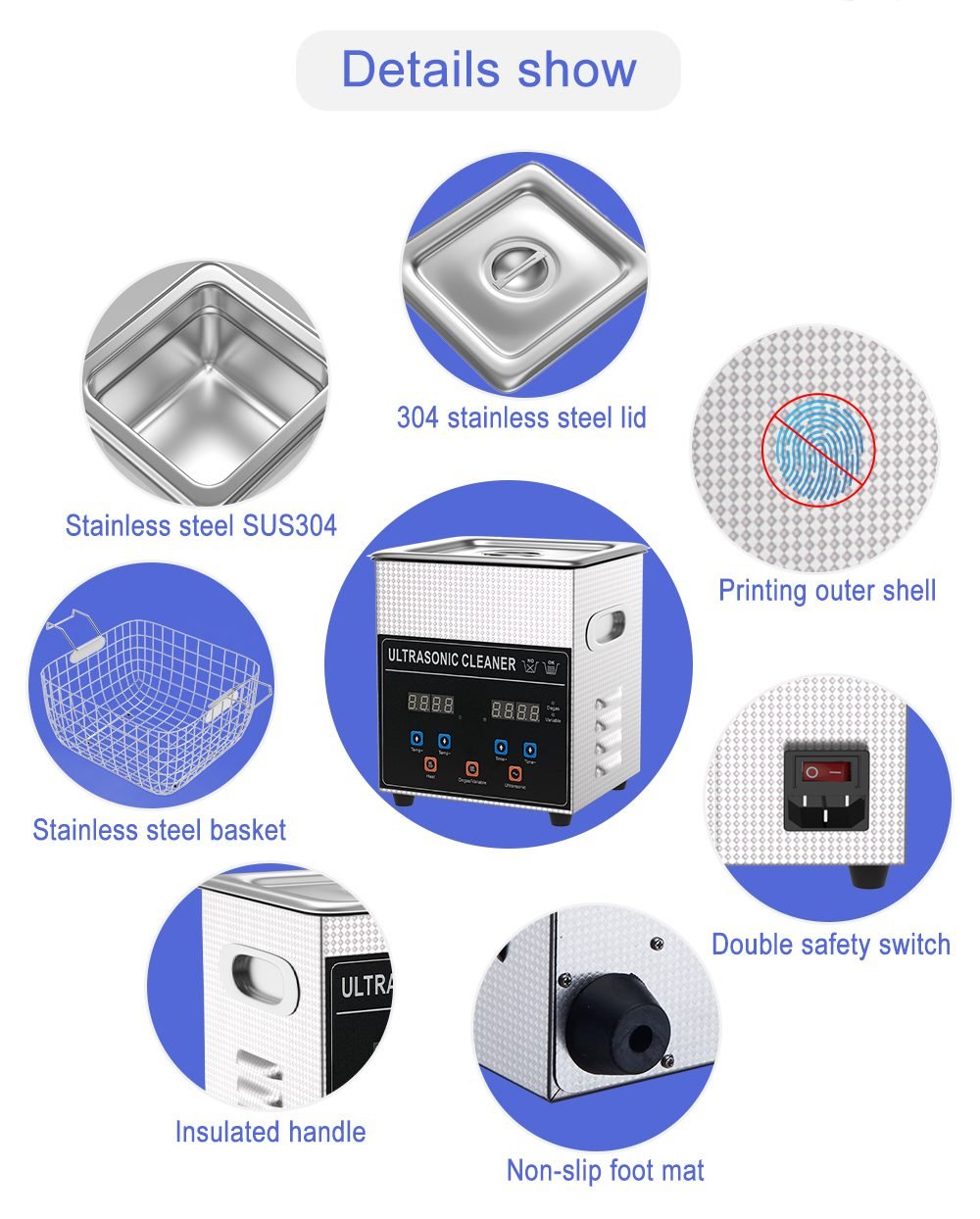

The CleaningSonic 010 Series Industrial-Grade Ultrasonic Cleaners are designed for demanding professional applications. Featuring a 2L large capacity 304 stainless steel tank coupled with industrial-grade transducers (40KHz high-frequency vibration, 40,000 times per second), these units provide powerful and stable cleaning performance. The intelligent temperature control system (adjustable 20-80°C) and precise digital timer (1-30 minutes) ensure efficient removal of various stains.

This series offers 6 configuration options including knob control and digital control, single power and dual power modes to meet different professional scenarios. The robust construction design, dual safety switch protection, and ergonomic handle ensure long-term reliable operation. As a professional manufacturer, we support comprehensive OEM/ODM customization services.

Product Specifications of Ultrasonic Cleaner with Timer

Model

010

010-1

010S

010S-1

010SD

010SD-1

Capacity

2.0L

2.0L

2.0L

2.0L

2.0L

2.0L

Ultrasonic Power

60W

120W

60W

120W

30W/60W

60W/120W

Heating Power

150W

150W

150W

150W

150W

150W

Frequency

40KHz

40KHz

40KHz

40KHz

40KHz

40KHz

Temp. Range

20-80°C

20-80°C

20-80°C

20-80°C

20-80°C

20-80°C

Timer Range

1-30 min

1-30 min

1-30 min

1-30 min

1-30 min

1-30 min

Control Type

Knob Control

Knob Control

Digital Control

Digital Control

Digital Control

Digital Control

Tank Material

304 Stainless Steel

304 Stainless Steel

304 Stainless Steel

304 Stainless Steel

304 Stainless Steel

304 Stainless Steel

Tank Size

5.9×5.31×3.94″

5.9×5.31×3.94″

5.9×5.31×3.94″

5.9×5.31×3.94″

5.9×5.31×3.94″

5.9×5.31×3.94″

Unit Size

6.89×6.3×7.87″

6.89×6.3×7.87″

6.89×6.3×7.87″

6.89×6.3×7.87″

6.89×6.3×7.87″

6.89×6.3×7.87″

Core Features & Functions of Ultrasonic Wave Cleaning

Industrial-Grade Core Components

304 Stainless Steel Tank: Corrosion-resistant, easy to clean, maintains shape over time

Industrial Transducers: 40KHz high-frequency vibration, 40,000 times per second, high energy conversion efficiency

Dual Transducer Configuration (010-1/010S-1/010SD-1): Provides more uniform and powerful cleaning

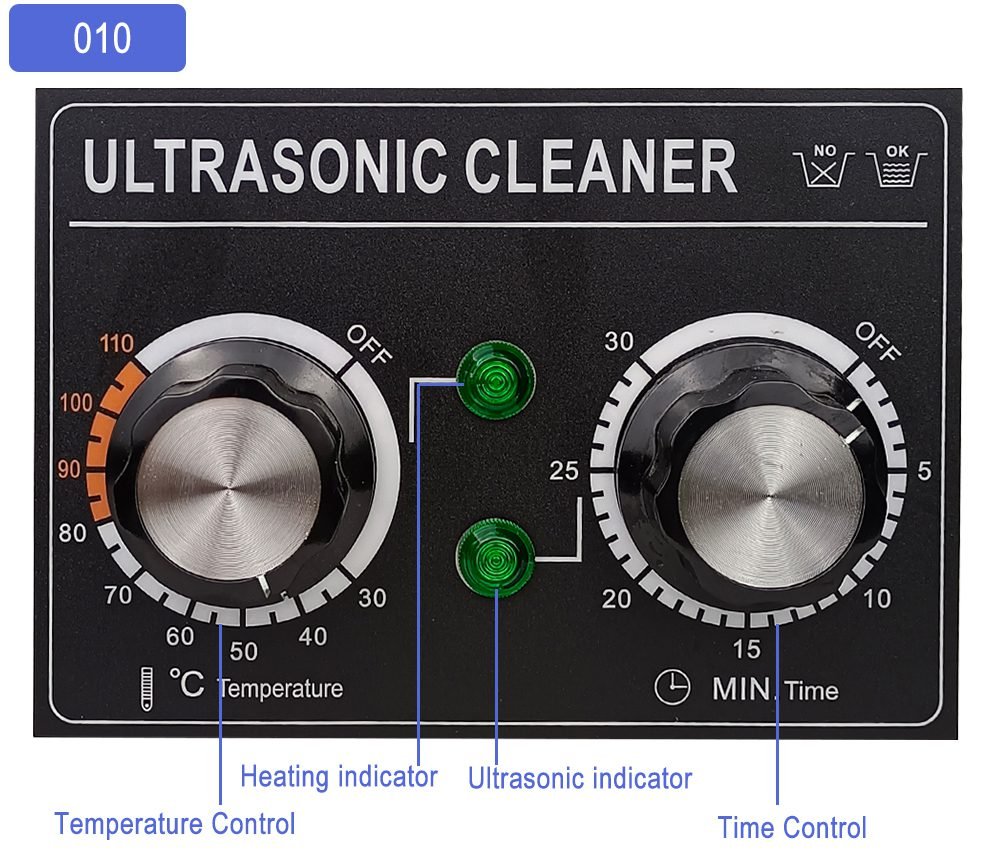

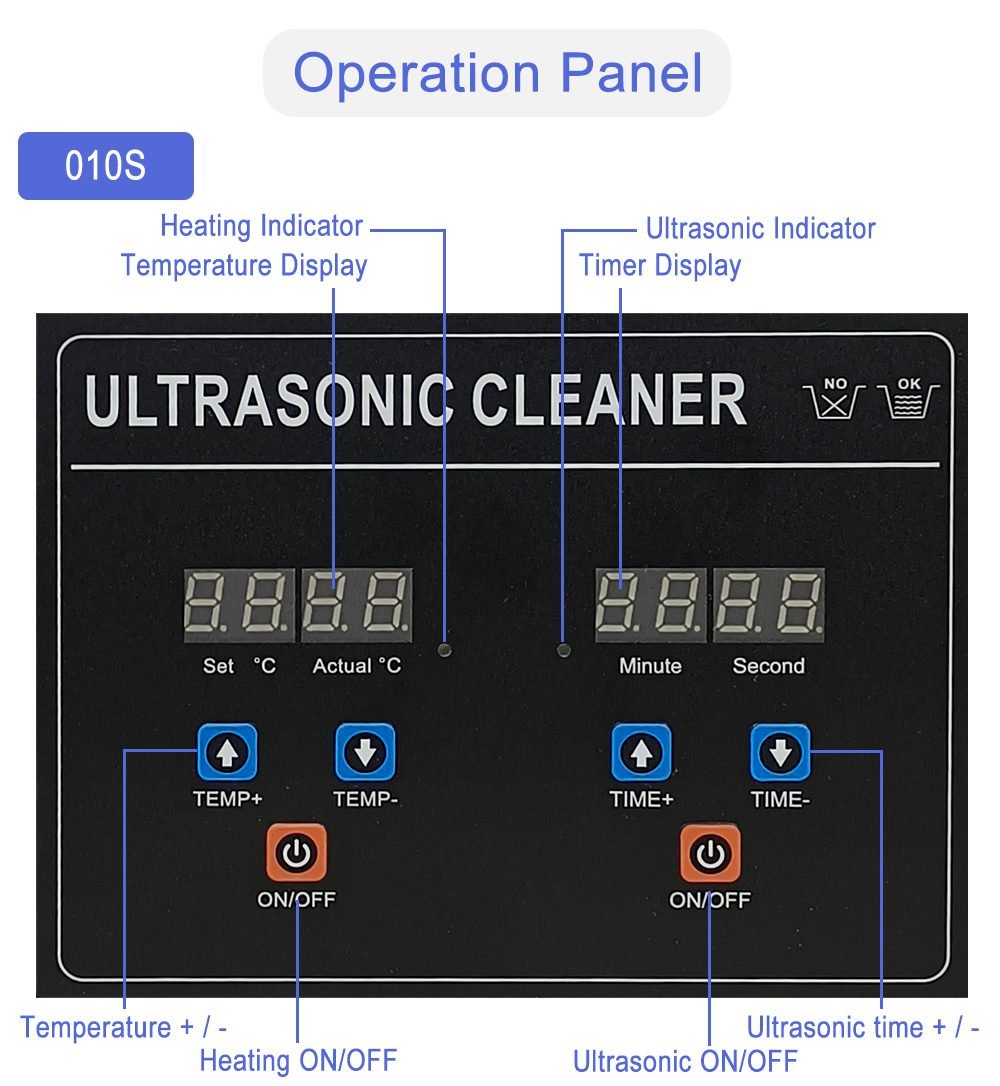

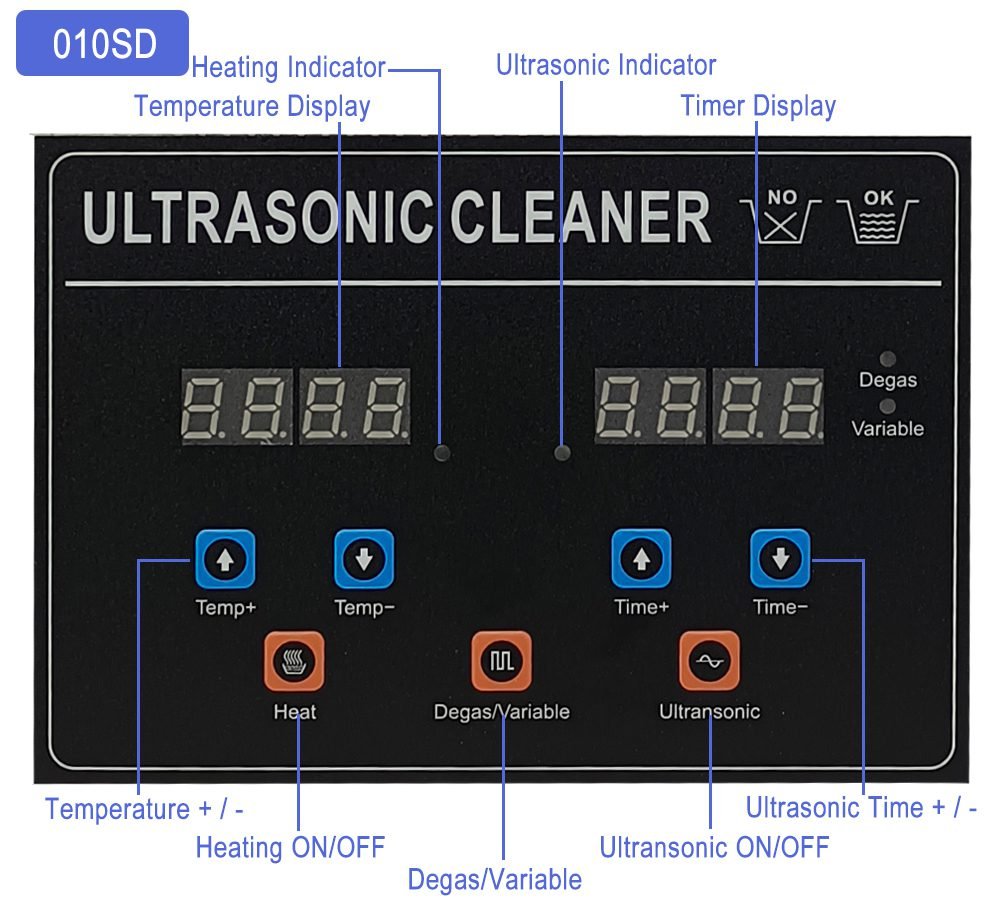

Professional Operation Panel

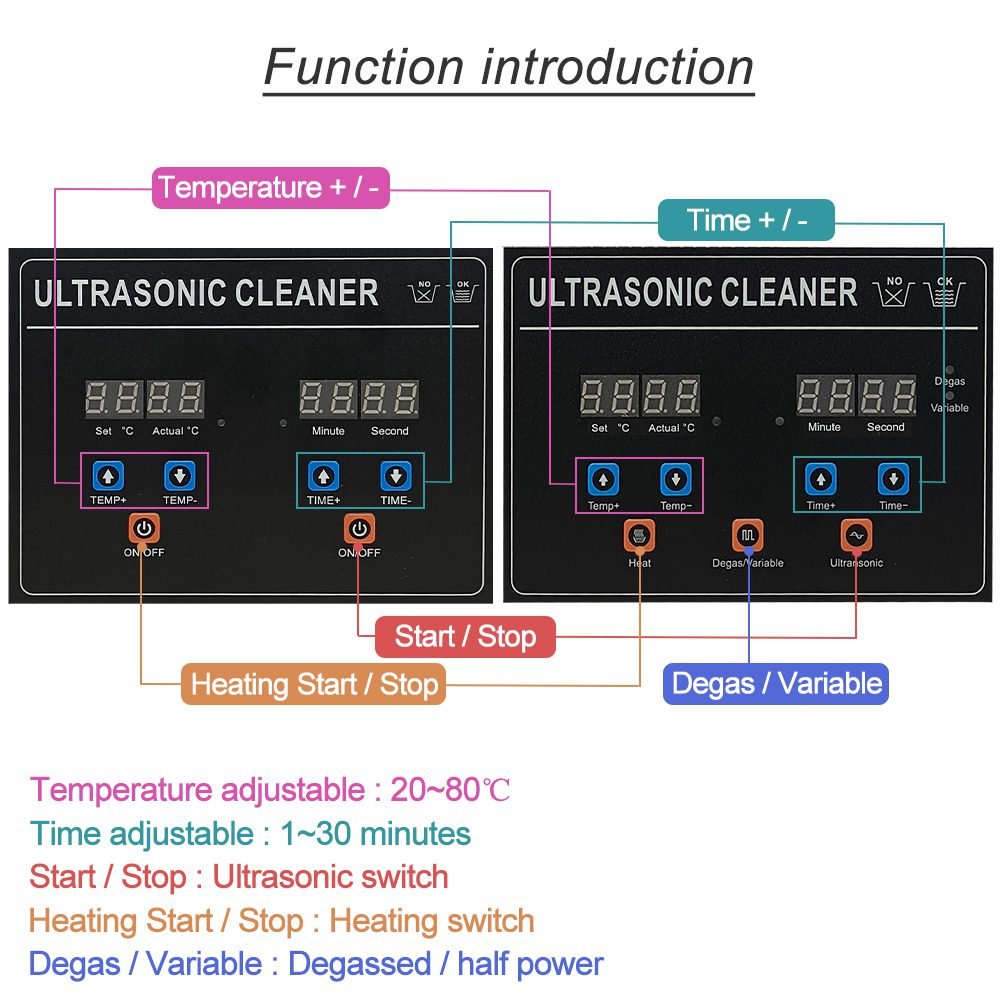

Temperature +/- precise adjustment buttons

Time +/- setting buttons (1-30 minutes adjustable)

Independent heating switch control

Independent ultrasonic switch control

Dual display interface (set value/actual value)

Safety & Ergonomic Design of High-Frequency Cleaning

Dual Safety Switches: Prevent accidental operation, ensure safe use

Insulated Handle: Heat-proof design for safer operation

Non-slip Feet: Stable placement, reduces vibration noise

Multi-angle Viewing Window: Clear monitoring of cleaning process

Printed Shell: Aesthetic and durable, supports brand customization

High-Efficiency Cleaning Technology

Heating accelerates stain decomposition, especially effective for oil and rust

Degas function optimizes cleaning solution penetration

Dual power modes adapt to different cleaning intensity requirements

Technical Advantages Explained of Professional Ultrasonic Cleaner

Industrial Transducer Technology

Uses professional industrial-grade piezoelectric ceramic transducers

40KHz frequency achieves optimal balance between cleaning effectiveness and item protection

High energy conversion efficiency with minimal power loss

Long-life design ensures stable continuous operation

Intelligent Temperature Control System

PID temperature control algorithm minimizes temperature fluctuation

Dual temperature display (set temperature/actual temperature)

Wide 20-80°C adjustment range adapts to different cleaning agent requirements

Structural Design Advantages

Integrated stainless steel structure, no welded seams, leak-proof

Optimized tank proportions maximize cleaning solution utilization

Ergonomic handle facilitates easy and labor-saving transport

Operation Guide of Lab Ultrasonic Cleaner / Laboratory Ultrasonic Cleaner

Equipment Installation & Preparation:

Place on a stable, dry work surface

Check if power voltage meets requirements

Add appropriate amount of specialized cleaning solution (recommended liquid level)

Insert stainless steel cleaning basket (if needed)

Standard Cleaning Process:

Place items to be cleaned into tank or basket

Set desired working temperature (20-80°C)

Set cleaning time (1-30 minutes)

Activate heating function (wait for temperature to reach set value)

Start ultrasonic cleaning function

After cleaning completion, turn off power and remove items

Rinse items with clean water, air dry or blow dry

Special Function Usage:

Degas Mode: Press ultrasonic switch 3 times before starting

Dual Power Selection (010SD series): Select appropriate power via panel

Temperature Hold: Can turn off ultrasound separately after heating completes

Product Advantage Comparison of Ultrasonic Cleaning for Micro Parts

010 Series vs Ordinary Cleaning Equipment:

More Powerful: Industrial transducers provide stable output, cleaning effectiveness improved by 40%

Better Materials: 304 stainless steel vs ordinary stainless steel, durability increased 3 times

More Precise Control: Digital temperature control vs mechanical, temperature accuracy ±1°C

More Functions: Professional features like degas, dual power, independent controls

Higher Safety: Safety designs including dual safety switches, insulated handle

010 Series vs Competing Products:

More Complete Configuration: 6 models meet different needs

Easier Customization: Comprehensive OEM support with quick response

Better Service: Professional technical support, complete after-sales protection

Higher Cost Performance: Significant price advantage with equivalent configuration

Expanded Application Scenarios of Ultrasonic Cleaning for Stainless Steel Components

Professional Manufacturing & Repair:

Jewelry Manufacturing: Cleaning semi-finished jewelry, castings, polishing residues

Watch Manufacturing & Repair: Cleaning movement parts, cases, bands

Eyewear Manufacturing: Batch cleaning of frames, lens processing residues

Precision Instrument Repair: Cleaning optical components, precision mechanical parts

Industrial Manufacturing:

Auto Parts Manufacturing: Cleaning spark plugs, injectors, sensors

Electronics Manufacturing: Cleaning PCB boards, connectors, precision components

Medical Device Manufacturing: Pre-processing surgical instruments, laboratory ware

Mold Manufacturing: Cleaning precision molds, cutting tools

Commercial Service Industry:

High-end Jewelry Stores: Providing professional cleaning services for clients

Luxury Repair Centers: Cleaning and maintaining high-end leather accessories

Professional Restoration Studios: Antique and artwork restoration cleaning

Research Laboratories: Professional cleaning of laboratory equipment

Investment Return Analysis

For End-Users:

Efficiency Improvement: Batch cleaning capability increases efficiency 10x over manual cleaning

Cost Savings: Reduces labor costs, decreases cleaning agent consumption

Quality Assurance: Standardized cleaning process ensures stable, controllable quality

Business Expansion: Can add professional cleaning services, creating new revenue streams

For Distributors:

Complete Product Line: Covers full range from entry-level to professional needs

Higher Profit Margins: Industrial-grade products support higher profit rates

Stronger Customer Loyalty: Professional equipment fosters long-term partnerships

Market Competitiveness: Unique functional configurations create differentiation advantages

Brand Building: OEM customization helps establish professional brand image

Quality Assurance System of Ultrasonic Cleaning for Laboratory Glassware

Manufacturing Standards:

ISO9001 Quality Management System certification

Strict incoming material inspection system

72-hour aging test for each unit

100% factory function testing

Component Quality Control:

Transducers: Imported piezoelectric ceramic materials, performance tested

Stainless Steel: Food-grade 304 material, thickness meets standards

Electronic Components: Brand-name components for stability and reliability

Control System: Independently developed, repeatedly tested and verified

After-Sales Service Commitment:

12-month quality warranty period

Lifetime technical support

48-hour fault response time

Long-term spare parts supply guarantee

Product Configuration Recommendations of Ultrasonic Cleaning for Ceramic Parts

Industry-Specific Recommendations:

Jewelry Manufacturing Industry:

Recommended Model: 010S-1 (Digital control, 120W dual transducers)

Recommended Accessories: Multi-compartment stainless basket, specialized jewelry cleaning solution, drying equipment

Usage Advantages: Thorough cleaning, doesn’t damage fine structures, batch processing capability

Tool Repair Industry:

Recommended Model: 010SD-1 (Digital control, adjustable dual power)

Recommended Accessories: Tool holding rack, heavy grease cleaning solution, rust inhibitor

Usage Advantages: Adjustable power for different tools, excellent degreasing effect

Multi-Application Scenarios:

Recommended Combination: 010S + 010SD-1

Application Strategy: Smaller model for daily cleaning, larger model for difficult stains

Cost Advantage: Flexible configuration, fast return on investment

Startups/Small Batch Production:

Recommended Model: 010 (Basic knob control)

Upgrade Path: Can upgrade to 010S or 010SD series later

Investment Advice: Meet basic needs first, upgrade as business expands

Send Inquiry

Hot Tags

#IndustrialUltrasonicCleaner #2LCleaner #304StainlessSteelTank #JewelryManufacturingEquipment #ToolCleaningMachine

#IndustrialTransducerCleaner #ProfessionalCleaningEquipment #OEMCustomCleaner #HeatedUltrasonicCleaning

#CS010UltrasonicCleaner #HighPowerCleaner #DualTransducerCleaner #PrecisionPartsCleaningEquipment

#AutoPartsCleaning #ElectronicComponentCleaning #MedicalInstrumentCleaning #LaboratoryCleaningEquipment